Here

advertisement

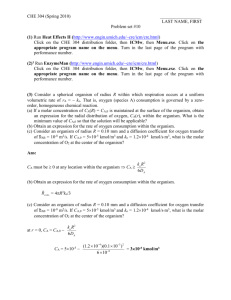

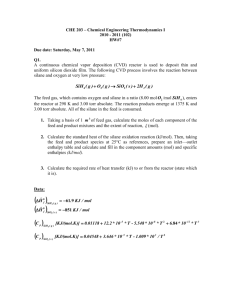

CHE 304 (Spring 2010) __________________ LAST NAME, FIRST Problem set #10 (1) Run Heat Effects II (http://www.engin.umich.edu/~cre/icm/cre.html) Click on the CHE 304 distribution folder, then copy the Heat2 folder to your flash drive or H:\ drive. Open this folder and click on the appropriate program name (Heat Effects II.exe). Turn in the last page of the program with performance number. (2) Consider a spherical organism of radius R within which respiration occurs at a uniform volumetric rate of rA = ko. That is, oxygen (species A) consumption is governed by a zeroorder, homogeneous chemical reaction. (a) If a molar concentration of CA(R) = CA,0 is maintained at the surface of the organism, obtain an expression for the radial distribution of oxygen, CA(r), within the organism. What is the minimum value of CA,0 so that the solution will be applicable? (b) Obtain an expression for the rate of oxygen consumption within the organism. (c) Consider an organism of radius R = 0.10 mm and a diffusion coefficient for oxygen transfer of DAB = 10-8 m2/s. If CA,0 = 510-5 kmol/m3 and ko = 1.210-4 kmol/sm3, what is the molar concentration of O2 at the center of the organism? (3) The following data as obtained in a batch reactor for the yeast Saccharomyces cerevisicae t(h) CC(g/L) CS(g/L) dCC/dt(g/Lh) 0 1 250 0.30 1 1.39 245 0.45 2 1.93 238 0.63 3 2.66 229 0.87 4 3.7 216 1.21 6 7.12 197 2.32 8 13.7 94.4 4.42 (a) Determine the rate law parameter max and Ks, assuming the data can be described by Monod Equation dCC CC = rg = max S C dt K S CS Use fminsearch with initial guess: max = 0.1 L/gh, Ks = 2 g/L (b) Determine the rate law parameter max and k, assuming the data can be described by Tessier Equation dCC C = rg = max 1 exp S CC dt k Use fminsearch with initial guess: max = 0.5 /h, k = 100 g/L Use Matlab to plot out the experimental and calculated rg for both models on the same graph. You need to put your own name on the graph using the Matlab statement “title” to receive credit for this problem. (4)1 Normal butane (A), C4H10, is to be isomerized to isobutane (B) in a plug-flow reactor5. The reaction is to be carried out adiabatically in the liquid phase under high pressure using essentially trace amount of a liquid catalyst, which gives a specific rate constant of 0.5 h-1 at 300oK. Calculate the fractional conversion of a PFR with a volume of 2.0 m3 necessary to process 163 kmol/h of a mixture 80 mol % n-butane and 20 mol % i-pentane, which is considered an inert. The feed enter at 330oK. k A k B b Data: HRx = 6,900 J/mol, Cp,n-B = CpA = 141 J/moloK, Cp,i-B = CpB = 141 J/moloK, Cp,i-P = k 161 J/moloK, activation energy = 65.7 kJ/mol, CA0 = 8.5 kmol/m3, Keq = = 3.0 at 333oK. kb (5) The hydrolysis of esters1, i.e., RCOOR’ + H2O RCOOH + R’OH frequently is catalyzed by acids. As the above hydrolysis reaction proceeds, more acid is produced and the concentration of catalyst increases. This phenomenon, known as “autocatalysis,” is captured by the rate equation rE = (k0 + k1[A])[E][H2O] Here k0 is the rate constant in the absence of the organic acid that is produced by the reaction. Given the following values: E0 (ester concentration in feed) = 1.0 mol/L W0 (water concentration in feed) = 1.0 mol/L A0 (acid concentration in feed) = 0 [R’OH] (alcohol concentration in feed) = 0 k0 = 0.01 L/molh, k0 = 0.20 L2/mol2h Assume that the reaction takes place in the liquid phase: a) Using Matlab plot 1/( rE) versus XE for 0 XE 0.7. You need to put your own name on the graph using the Matlab statement “title” to receive credit for this problem. b) What kind of continuous reactor system would you use if a final ester conversion of 0.60 were desired, and if the reaction were to take place isothermally. Choose the reactor or combination of reactors that has the smallest volume. Justify your answer. (6) Use Comsol Multiphysics to simulate an adiabatic reactor (Example 7.6-2 in the notes). Turn in Figure 3, 4, 5, and 6 of this example. 5 1 Fogler, H. S., Elements of Chemical Reaction Engineering, Prentice Hall, 1999, pg. 454 Roberts, G. W., Chemical Reactions and Chemical Reactors, Wiley, 2006, pg. 59, P. 3-10