ChE 471

advertisement

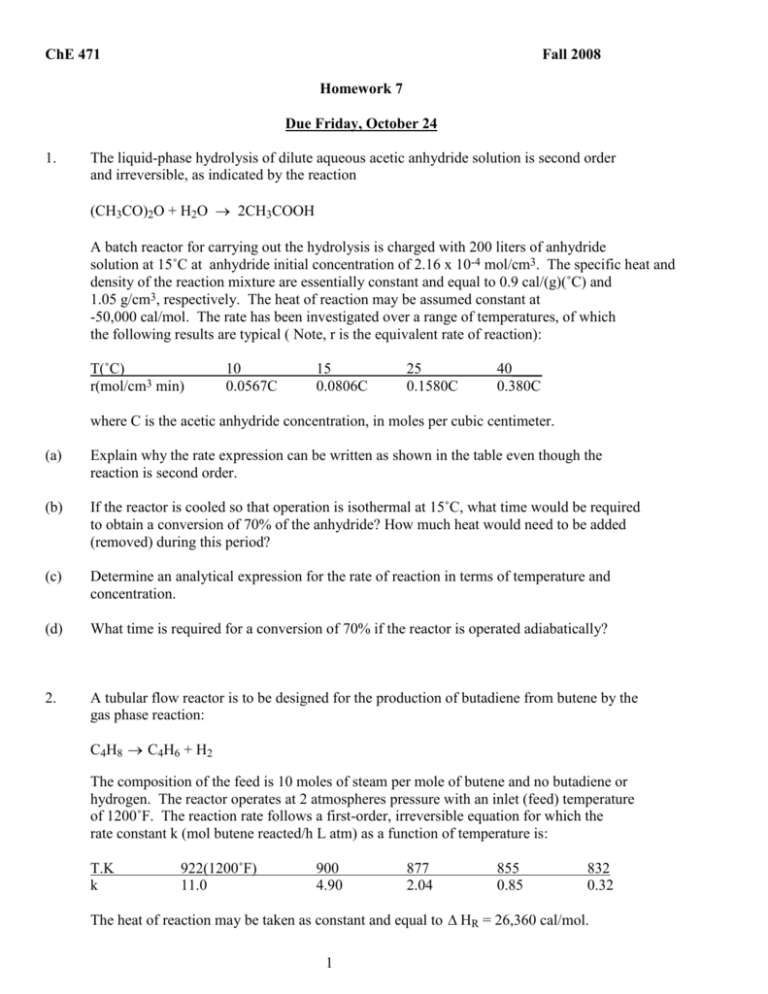

ChE 471 Fall 2008 Homework 7 Due Friday, October 24 1. The liquid-phase hydrolysis of dilute aqueous acetic anhydride solution is second order and irreversible, as indicated by the reaction (CH3CO)2O + H2O 2CH3COOH A batch reactor for carrying out the hydrolysis is charged with 200 liters of anhydride solution at 15˚C at anhydride initial concentration of 2.16 x 10-4 mol/cm3. The specific heat and density of the reaction mixture are essentially constant and equal to 0.9 cal/(g)(˚C) and 1.05 g/cm3, respectively. The heat of reaction may be assumed constant at -50,000 cal/mol. The rate has been investigated over a range of temperatures, of which the following results are typical ( Note, r is the equivalent rate of reaction): T(˚C) r(mol/cm3 min) 10 0.0567C 15 0.0806C 25 0.1580C 40____ 0.380C where C is the acetic anhydride concentration, in moles per cubic centimeter. (a) Explain why the rate expression can be written as shown in the table even though the reaction is second order. (b) If the reactor is cooled so that operation is isothermal at 15˚C, what time would be required to obtain a conversion of 70% of the anhydride? How much heat would need to be added (removed) during this period? (c) Determine an analytical expression for the rate of reaction in terms of temperature and concentration. (d) What time is required for a conversion of 70% if the reactor is operated adiabatically? 2. A tubular flow reactor is to be designed for the production of butadiene from butene by the gas phase reaction: C4H8 C4H6 + H2 The composition of the feed is 10 moles of steam per mole of butene and no butadiene or hydrogen. The reactor operates at 2 atmospheres pressure with an inlet (feed) temperature of 1200˚F. The reaction rate follows a first-order, irreversible equation for which the rate constant k (mol butene reacted/h L atm) as a function of temperature is: T.K k 922(1200˚F) 11.0 900 4.90 877 2.04 855 0.85 832 0.32 The heat of reaction may be taken as constant and equal to HR = 26,360 cal/mol. 1 Similarly the specific heat of the feed stream may be regarded as constant and equal to 0.5 Btu/lb ˚R. (a) What would be the volume required for a conversion (of butenes) of 20% if the reactor were operated isothermally at 1200˚F with a butene-plus-steam feed rate of 22 lb mol/h? What is the heat addition ( removal) requirement? (b) It is desired to determine the conversion as a function of reactor volume (ft3) for adiabatic operation if the feed rate is 2.0 lb mol of butene per hour and 20 lb mol of steam per hour. Demonstrate your ability to solve this type of problem by calculating the reactor volume for conversions (of butenes) of 10 and 20%. What changes in operating conditions could be employed to reduce the volume required for a given conversion? 3. A first-order irreversible (liquid-phase) reaction is carried out in a continuous flow stirred-tank reactor (CSTR). The density is 1.2 g/cm3 and the specific heat is 0.9 cal/(g)(˚C). The volumetric flow rate is 200 cm3/s and the reactor volume is 10 liters. The rate constant is: k = 1.8 x 105e-12,000/RgT s-1; Rg = universal gas constant in (cal/mol K) where T is in degrees Kelvin. If the heat of reaction is HR = -46,000 cal/mol and the feed temperature is 20˚C, what is the steady state temperature and conversion in stable, adiabatic operation at a feed concentration of 4.0 mol/liter? 4. The reaction between sodium thiosulfate and hydrogen peroxide in dilute aqueous solution is irreversible and second order in thiosulfate. The rate constant for the thiosulfate is the following function of temperature: 18300 (cm3/mol s) ; k = 6.85 x 1014 exp Rg T Rg= gas constant (cal/mol K) Reaction stoichiometry indicates that 2 moles of H2O2 react with one mole of Na2S2O3. The heat of reaction at 25˚C is HR = -131,000 cal/mol. Kearns and Manning (AIChE J., 15, 660 (1969)) experimental studies in a continuous flow stirred tank reactor included the following conditions: Reactor volume Feed temperature Feed rate = 2790 cm3 = 25˚C = 14.2 cm3/s Consider adiabatic operation and feed concentration of 2.04 x 10-4 (mol/cm3) and 4.08 x 10-4 g (mol/cm3) of thiosulfate and hydrogen peroxide, respectively. What would be the thiosulfate conversion and temperature in the reactor effluent? 2 3