office of information technology equipment, infrastructure, and wiring

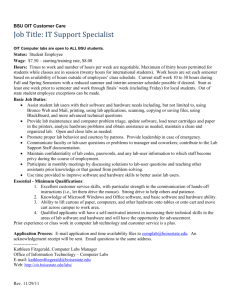

advertisement