7774 Set up and maintain computerised photographic grading

advertisement

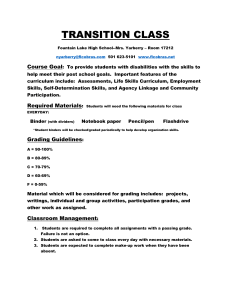

7774 version 4 Page 1 of 5 Set up and maintain computerised photographic grading equipment for food products Level 3 Credits 8 Purpose This unit standard is for people who are currently working in jobs which involve the set-up and maintenance of sophisticated sorting equipment which uses photographic images to identify and reject out-of-specification food products. People credited with this unit standard are able to: use safe working practices; set up photographic grading equipment for food products, maintain photographic grading equipment for food products, and repair photographic grading equipment for food products. Subfield Food and Related Products Processing Domain Food and Related Product Production Equipment Status Registered Status date 26 November 2007 Date version published 26 November 2007 Planned review date 31 December 2012 Entry information Open. Accreditation Evaluation of documentation and visit by NZQA and industry. Standard setting body (SSB) Competenz (Food and Beverage) Accreditation and Moderation Action Plan (AMAP) reference 0111 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 Legislation relevant to this unit standard includes but is not limited to the: Health and Safety in Employment Act 1992; Health and Safety in Employment Regulations 1995; Food Act 1981; Food Hygiene Regulations 1974; Food (Safety) Regulations 2002; Resource Management Act 1991; and their associated regulations and subsequent amendments. New Zealand Qualifications Authority 2016 7774 version 4 Page 2 of 5 2 Definitions Equipment refers to equipment used for photographic grading or colour sorting; Organisational procedures refer to documents that include: worksite rules, codes, and practices; equipment operating instructions; production specifications; documented quality management systems; and health and safety requirements. PPE refers to personal protective equipment and may include but is not limited to: protective clothing, gloves, safety glasses/headwear/footwear, hearing protection, safety devices. 3 Competence is to be demonstrated on at least three occasions of setting up and maintaining computerised photographic grading or colour sorting equipment for food products that includes any two of – potato chips, diced carrots, swede, potato, broad beans, mixed vegetables. Elements and performance criteria Element 1 Use safe working practices. Performance criteria 1.1 PPE is used in accordance with organisational procedures. 1.2 Work environment is clean and free from hazards in accordance with organisational procedures. Range 1.3 hazards to – personnel, product, plant. Documentation is referred to and/or completed in accordance with organisational procedures. Element 2 Set up photographic grading equipment for food products. Performance criteria 2.1 Equipment is set up and operational within agreed timeframe. 2.2 Photographic grading equipment operation is correct for vegetable type and specification. 2.3 Optical path is clean and aligned to equipment specifications. Range 2.4 optical path – direct, indirect video camera lens, fluorescent tubes, mirrors. Product rejection ratio is correct and meets production supervisory staff rejection ratio requirements. New Zealand Qualifications Authority 2016 7774 version 4 Page 3 of 5 2.5 Photographic grading equipment conveyer belts are clean, serviceable, at correct tension, and follow correct track. Range serviceable belts – crack free, reliable, surface unworn, unperished. 2.6 Pressure within air and water systems complies with equipment specifications. 2.7 Test equipment used for set-up of photographic grading equipment is calibrated, and measurement accuracy is within equipment manufacturer's stated tolerance. Range 2.8 Correct tools and test equipment for set up of photographic grading equipment are used in specified manner. Range 2.9 test equipment includes but is not limited to – vibration listening devices, multi-meters, oscilloscopes. tools include but are not limited to – spanners, screwdrivers, wrenches, keys. Set-up of photographic grading equipment complies with organisational procedures and legislation. Element 3 Maintain photographic grading equipment for food products. Performance criteria 3.1 Operation of photographic grading equipment is maintained within specification. 3.2 Motor bearings of photographic grading equipment are quiet, within wear tolerance specification, and lubricated in specified manner. 3.3 Photographic grading equipment motor running currents are within rated current limits, and insulation resistance of windings is correct. 3.4 Transmission of photographic grading equipment is quiet, conforms to tolerance specifications, and is lubricated in specified manner. Range 3.5 transmission – gearbox, chains, chain drive, sprockets. Optical path of photographic grading equipment is clean and meets specification. Range optical path – camera lens, fluorescent tubes, mirrors. 3.6 Belts are clean, at correct tension, and follow correct track. 3.7 Pressure within air and water systems conforms to equipment specifications. New Zealand Qualifications Authority 2016 7774 version 4 Page 4 of 5 3.8 Maintenance is planned and coordinated with stakeholders, and production downtime is minimised. Range 3.9 stakeholders – operators and/or production supervisors. Maintenance of photographic grading equipment complies with organisational policies and procedures, and legislation. Range policies and procedures – service manuals and/or safety and/or codes of practice and/or agreed and defined best practices. Element 4 Repair photographic grading equipment for food products. Performance criteria 4.1 Faults on photographic grading equipment are identified and diagnosed, and photographic grading equipment is repaired within a timeframe that optimises production performance. Range faults – mechanical, water pressure, air pressure, bearing, gear box, transmission, broken parts, electrical; alignment related; optical. 4.2 Photographic grading equipment is restored to specification. 4.3 Faults are located, and repair is completed in a manner and within a timeframe that maximise equipment performance, and minimise cost and waste. 4.4 Problems to repairing photographic grading equipment are identified, and solutions are developed to optimise performance. Range 4.5 Photographic grading equipment repair complies with organisational policies and procedures, and legislation. Range 4.6 problems – availability of equipment and/or replacement parts and/or personnel; specialised expertise and/or legislative requirements; policies and procedures – service manuals and/or safety and/or codes of practice and/or agreed and defined best practices. Opportunities to improve repairing of photographic grading equipment are identified, and are actioned with personnel responsible for initiating changes. Range opportunities – reduced maintenance cost and/or reduced maintenance downtime. New Zealand Qualifications Authority 2016 7774 version 4 Page 5 of 5 4.7 Stakeholders are informed of repair status and estimated completion time in a manner and within a timeframe that promotes goodwill. Range 4.8 Correct tools and test equipment are used in specified manner in accordance with organisational procedures. Range 4.9 stakeholders – operators, production line supervisors, managers, colleagues and/or contractors. tools and test equipment – spanners, screwdrivers, wrenches, keys; vibration listening devices, multi-meters, oscilloscopes. Guards and interlocks of photographic grading equipment are in correct position during maintenance. Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact Competenz qualifications@competenz.org.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016