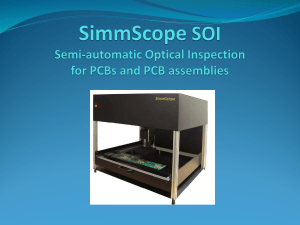

Automatic optical inspection systems

advertisement

Automatic optical inspection systems In the SMT process, the migration to smaller components are driving the implementation of AOI machines. 1. Passive components: smaller components (0402/0201) utilization 1206 = 0805= 0603 = 0402 = 0201 = 3.2 x 1.6 mm 2.0 x 1,3 mm 1.6 x 0.8 mm 1.0 x 0.5 mm 0.6 x 0.3 mm 2. Large utilization of ultrafinepitch and BGA and uBGA components. 3. Higher speed placement equipment. Automatic optical inspection systems The issue is not if we have to use an AOI machine, but understand where in the process it is most profitable: after the screen printer, after the pick and place or after the oven? The list of the main failures that can be caught with the use of the AOI machine can help us on this analysis. Fail Excessive paste Missing solder paste Misaligned solder paste Poor solder paste Smashed solder paste Missing components Reversed components Misaligned Components Wrong Polarity Wrong component Cracked component Aoi after screen printer X X X X X Aoi after pick and place ( X) (X) (X) (X) ( X) X X X X X X Missing/ bent lead(s) Tombstoned Poor solder joint No solder joint Short circuit (X) AOI after the oven X X X X X X X X X X X X X X X Automatic optical inspection systems 1. AOI after the screen printer Since the screen printer is the first stage, every defect created will be passed on to the next process. The strategy behind using post print AOI is to perform 2D or 3D paste inspection. The volume measurement is critical in the smaller componets (0201) and the ultra fine pitch components. 2. AOI after placement Placement of an AOI at this location will identify a high percentage of defects during the SMT process including some caused at screen printing .The failures detected at this step can be easily detected and reworked. 3. AOI after the oven The system can theorically give you the opportunity to identify all defects caused during the SMT process but inherently has these disadvantages: - Failures identified have a high rework cost. - The feedback on the process is not in real time ....all boards in reflow oven be defective. - The overkill factor is critical due to inherent variability of the solder joint image. Bad, missing and cold solder joints are not detected with high repeatability. Consequently, much time is spent fine tuning each AOI program. - The pick and place operation cannot be controlled by SPC analysis because the addition of reflow masks problems otherwise contained by real time SPC feedback Automatic optical inspection systems: VIM II Failure sample: Insufficient capacitor metallization The machine controls component positioning after placement. The system verifies by pattern matching at the component level giving us the opportunity to inspect with high accuracy. Additionally, since it utilizes centroid data as an integral part of that inspection, it offers real time Statistical Process Control of placement accuracy. Automatic optical inspection systems: VIM II Main Features Each point represents individual placements of the component selected. Max speed 0,085 sec/comp Accuracy (+/- 0,015 mm) Near Zero Overkilling Easy to be programmed Easy maintenance Real Time SPC. With this graph, you can immediately evaluate placement performance for each component real time. This feature assists not only with placement program optimization, but also provides immediate feedback, relative to all types of process changes. ( program variations, feeders, nozzles etc.) Reports have been developed to analyze positioning accuracy by product, by lot, by hours. Additional reports can be added as desired by the customer. Features Max speed: 0.085 sec/comp Accuracy: (+/- 0.015 mm) Near Zero Overkill Easy programming Inspects for missing, misplaced, wrong, polarization, cracked, broken, and more. Easy, flexible programming. Individual components can be reprogrammed easily without reprogramming an entire area. Standard Library for passive components. (Passive components have “don’t care area’ pre-programmed) Executes 45,000 tests per hour CAD Data or machine data may be downloaded to minimize downtime. Programmable rail width In line or off-line capability Test optimization function determines fastest path. 8 camera lighting sections may be individually programmed for best contrast Tests individual cards or multiple panels Unique components can be added to the component library Markings Identification. This can be programmed for “spot checking” for statistical analysis. Statistical symbolization checking. Statistical control prior to reflow . SPC can measure the deviation and provide real time feedback. Component model images are optimized to produce near zero overkill. Can check 0201 with no modifications to camera Extremely low maintenance. Affordable cost Data reporting. All data can be used for statistical analysis. SMEMA compatible Questions /Answers 1. Who is Protech? Protech Electronics is a sales / engineering firm based near Rome, Italy. Protech has exclusive rights as marketing reps in Italy for Ersa, Philips, Knodel. VIM II , and Optitest. Protech engineering is responsible for development, and ongoing support for VIM II and Optitest as well as development of new products. 2. How many units in operation worldwide? 67 Units currently in operation worldwide. Most units are located in Italy. The machine was developed by Protech specifically for EEMS, Inc. Rieti , Italy. It was so successful that it is now being marketed worldwide. 3. What companies currently use the system? Currently, EEMS (formerly Texas Instruments), a large memory house has 8 units in production. Others machines are located throughout Europe. Additionally, a VIM II is currently under evaluation by JBIL. 4. How many units in operation in USA? Recon has recently been awarded exclusive rights to market the machines in North America. Several companies are strongly considering the machine at this time. 5. Who is going to support the machine in the USA? Recon / Protech have a longstanding partnership. Upon delivery of the first machine in the USA, 3Q 2004, Protech Electronics provided on-site training Recon engineering. Additionally, Protech Engineering has the capability to access each machine’s onboard software via the internet from anywhere in the world. However, since thousands of hours have been logged on the machines, little or no offline support is anticipated. 6. Spare parts and service. Recon will stock a complete inventory of consumable spare parts, along with an inventory of complete machines. 7. Warranty? 1 Year Parts / service warranty. 8. Website? www.protechelettronica.it The VIMII is featured.