Advances in AOI Technology.

Advances in AOI

Technology.

A Taster for our next

Seminar

Keith Bryant

Technology Editor SMT Today Magazine

Chairman SMART Group

Your Delegate Webinar Control Panel

Open and close your panel

Full screen view

Submit text questions during or at the end

Visit the website www.smartgroup.org

Advances in AOI

Technology.

A Taster for our next

Seminar

Keith Bryant

Technology Editor SMT Today Magazine

Chairman SMART Group

Visit the website www.smartgroup.org

Through The Eye Of A Needle

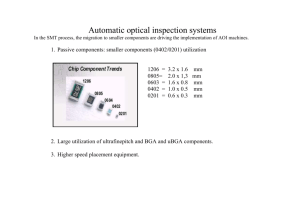

Chip Size and Spacing Options

Chen, et al.; ASSEMBLY PROCESS RESEARCH ON 01005 CHIP

COMPONENTS IN LEAD-FREE SYSTEM; SMTAI-06

Visit the website www.smartgroup.org

Ball Grid Arrays and QFN’s

Package on Package (PoP)

Flash Memory (Top)

+ =

Logic (Bottom)

Courtesy of Spansion

Visit the website www.smartgroup.org

Inspection Options

Manual Options

Magnifiers / Comparators

Digital Imaging Devices

Video Microscopes

Eyes

Inspection Options

Manual Options

Compact, ergonomic design

Digital zoom from 4x to 160x

Image capture and video output

Large workspace with sliding stage

for easy inspection and handling of PCB

Very simple to use lifted lead Misplacement another angle cold solder joint another angle

Visit the website www.smartgroup.org

Reliability of Visual Inspection

Solder Joint Visual Inspection of the same PC Board

44 %

Inspection Options

Automatic Options

FT (Functional Test) of finished product

ET/FP (Electrical Test/Flying Probe) of partial or finished assemblies

ICT (In Circuit Test) of circuits/components on PCB

AXI / XI (Automatic X-ray Inspection) for soldering and presence of components

A O I (Automatic Optical Inspection) for soldering and components

SPI (Solder Paste Inspection)

Visit the website www.smartgroup.org

Where do you place an AOI System?

In-Line

To check Solder Paste (2.5 or 3D)

To check Part Placement

To check solder post reflow

Solder Paste Placement

Parts &

Solder fillets

Where do you place an A O I System?

Off-line

Test for all three defect ty pes

O r test at any stage

Printer

X

Mounter

X

Reflow

X

Visit the website www.smartgroup.org

Solder Paste

Deposit (Brick)

Insert Picture of brick

Precise Volume (l, w, t) or ( D, t)

◦ Metal

◦ Flux (Can be an issue)

Precise Location (x, y, θ )

Post Print Inspection

2-D Inspection detects bridges, inadequacies, and checks alignment

◦ AOI on-board Printers is a recent innovation

◦ In-Line or Off-Line

3-D Inspection checks above as well as solder paste height, allowing volume calculation but at a slower rate

◦ In-Line or Off-Line

Visit the website www.smartgroup.org

DEFECT GENERATION

60 % of Assembly defects originate in the solder deposition process.

H-P Study in late 1980 ’ s

Confirmed by ITM and other evaluations of client ’ s defect data

Solder Paste Printing Fish Bone

Equipment Methods

Printer

Snap-Off

Squeegee Pressure

Alignment

Stencil

Holder

Squeegee

Humidity

Solder

Paste

Materials

Stencil

Temperature

Environment People

Training

Authority

Awareness

Visit the website www.smartgroup.org

Pre Reflow AOI Inspects:

Component Presence and Position

Correct Component

Orientation / Polarity

Skew / Mis-alignment

Lost or Extra components

Replaces the DANGEROUS Tweezer

People!

Pre Reflow Inspection

Purpose:

Find placement defects

It is much cheaper to fix them here

Components don’t self-align with

Lead-Free

Visit the website www.smartgroup.org

Good Solder Joints

Reliable Interconnection

Component Location

Solder Volume

Wetting

Residues

Post Soldering Inspection

Purpose: Find defects that include soldering defects and placement defects

Copyright 2007- 2008 ITM

Visit the website www.smartgroup.org

Post Soldering AOI Inspects:

Component Presence and Position

Correct Component

Orientation / Polarity

Skew / Mis-alignment

Tombstoning

Opens

Shorts

Post Soldering Inspection

AOI here is not easy !

Post-Reflow Inspection is difficult -

“ Good ” Solder joint difficult to

“ define ”

Solder joints are shiny and hard for some optical systems to “ see ” .

Visit the website www.smartgroup.org

A O I

Technology Variables

Inspection technologies / principles

Colour vs. B/W analysis

Capturing devices (cameras or scanners)

Optics (Lenses, Moray or LCOS)

Software, algorithms and libraries

Lighting, type, colours and controls

2D, 2.5D, Pseudo 3D and ‘Real’ 3D

A O I Inspection technologies / principles

Solutions available

Black and White Image Recognition

Scanner Types (OCR)

C o l o u r moving cameras

Colour comparator imaging (OCR)

Colour synthetic imaging

Multiple Cameras (2.5D or Pseudo3D imaging)

Visit the website www.smartgroup.org

A O I Inspection technologies / principles

Inspection technologies

Different calculation principles can be categorized as follows:

1. Correlation (picture comparison) ~ OCR

2. Synthetic modeling

3. Vector modeling

A O I Types

AOI Correlation principle

“Average” picture creation

Picture comparison using an average picture, based on the

“average” pixel-value of multiple pictures of the same component.

Most used in scanner type and entry level AOI systems.

Operator display in Colour (Colour Camera) but actual imaging & inspection in grey scale and Black and White

Formula for Average Picture:

Image = (Image 1 + Image 2 + … + Image N) / N

Visit the website www.smartgroup.org

A O I Types

Correlation principle

Advantages:

"Self learning“

adding a new picture on every false or real alarm

Fast programming

Flexible

Low Cost

A O I Types

Correlation principle Disadvantages:

Risk of “Slip” when programmer adds “wrong pictures”

Alternative components require renewed debugging

Visit the website www.smartgroup.org

A O I Types

AOI Synthetic Modeling principle

Picture comparison using a sy nthetic picture, deriv ed from real picture by image processing

U sed in more adv anced camera systems, sometimes in combination w ith v ector based models

Normal: Sy nthetic:

A O I Types

Synthetic Modeling advantages:

Based on a single image reference

Tolerance setting done by modeling graphical filters

Flexible (low volume, high mix)

Easy use of alternative components

“STAMP”

Ability to add “ Special Features ”

Visit the website www.smartgroup.org

A O I Types

Synthetic Modeling disadvantages:

Experience, Skill + Library required to make modeling easier (operator training)

More powerful computer needed

(higher resolution graphics & imaging)

A O I Types

AOI Vector Modeling principles

numbers (not images)

Many inspection fields for each component component / solder joint

Usually only Grey-scale analysis

Both “Self Learning” (via statistics) or “Fixed

1001

Visit the website www.smartgroup.org

A O I Types

Vector Modeling advantages:

Measurements based on exact numbers

Sometimes Rotation measurements possible

Simple calculations (only grey-scale and small frames)

Fast in combination with fast hardware

Pseudo 3D possible in case of angled cameras

A O I Types

Vector modeling disadvantages:

Need large library

(extensive programming and experience)

New components or design need new modeling

(for library)

Modeling odd components (THT) complicated

Limited flexibility (e.g. low volume-high mix)

Additional technology for text needed

Visit the website www.smartgroup.org

A O I Types

Colour vs. B/W in AOI

More powerful detection (e.g. dark green

PCB with black components)

24bit vs. 8bit measurements

Requires more processing power and inspection time

Easier interface for Operators,

Programmers, Repairers

SMT industry uses many colours.

A O I Types ~ B&W vs. Colour

Dark components on dark green PCB

Nor mal lighting Gr ey only

- Poor contrast

- Difficult detection

Nor mal lighting Colour

- Good contrast

- Easy detection

Nor mal lighting Gr ey only

- Poor contrast

- Difficult detection

Nor mal lighting Colour + signal emphasis

- Good contrast

- Easy detection

Visit the website www.smartgroup.org

A O I Types

Camera types

Two different Image Capturing devices:

Moving XY Field Camera

Line Camera or “Scanner”

A O I Types

Moving XY Field Camera

Camera/Light head is moving

Mixed resolutions possible in one program

Lighting can be changed per inspection location

Omni directional lighting (360 degrees)

Larger Field Of View (FoV) increases speed

Orthogonal camera(s): Top view

(more cameras = more speed)

Angled cameras: Side view ~ Pseudo 3D speed slows down + increases programming time

Live picture easy for programming/debugging

Higher Pixel count image slows system, requires bigger PC and reduces depth of field

Stitching of image can also be an issue

Visit the website www.smartgroup.org

A O I Types

“Line-camera“ or Scanner

Fast scanning

Scanning time independent of component numbers

Single resolution per board

Single lighting per board (not 360 degrees)

Large file sizes

Inexpensive

A O I Types

Lighting systems

Top Light (around lens)

70-80 degrees normal inspection

White

Visit the website www.smartgroup.org

A O I Types

Lighting systems

Side light (around lens)

45 degrees

Better v isibility of text

V isibility of solder meniscus

Red

A O I Types

Lighting systems

Coloured lighting at different angles

Lights can be in different colours to help algorithms to “see” more information

White

+

Red

Visit the website www.smartgroup.org

A O I Types

Lighting Systems

Coaxial light ( through the lens)

Prism Construction

Light beam lands with 90º on PCB surface

High contrast between flat and non-flat items

Excellent visibility of solder defects

Top

White

Gold

A O I Types ~ Lighting

Silv er Tin O SP

C o

A xial

More lighting options offer a measurable difference

Visit the website www.smartgroup.org

A O I Types ~ Lighting effects

Melf Diode polarities

Nor mal lighting (Grey only)

- Poor contrast

- Difficult detection

Nor mal lighting Colour

- Good contrast

- Easier detection

Nor mal lighting Colour + Synthetic Imaging

- Good contrast

- Easy detection

Coaxial lighting + Colour Emphasis

(before Synthetic Imaging)

- Best contrast

- Easy detection and programming

A O I Types ~ Lighting effects

SOT23 Upside Down detection by joints

Component OK:

Nor mal lighting

- C ontrast O K

- Large meniscus v ariation

Component OK:

Red Side lighting (before Synthetic Imaging)

- Meniscus emphasized

- Easy detection w ith focus on meniscus

Component NOT OK (upside down):

Red Side lighting (before Synthetic Imaging)

- If SO T upside dow n, meniscus is gone

- C lear detection by Red Side light

Visit the website www.smartgroup.org

A O I Types / Solder ~ Lighting effects

Solder joint inspection: 4 ways

Synthetic modeling

Using different lighting settings

Sidelight Extraction + Synthetic modeling

A O I Types / Solder ~ Lighting effects

Solder joint inspection: 4 ways

Greyscale Thresholds

Set upper and lower limits

Sidelight Extraction & Histogram analysis

Visit the website www.smartgroup.org

How A O I Works ~ Component Library

1 ~ Automatically scan & map the board

2 ~ Import CAD / Gerber data

How A O I Works ~ Component Library

3 ~ Stamps

• Select component stamp from library.

• Or create stamp by selecting area around component.

Visit the website www.smartgroup.org

How A O I Works ~ Component Library

4. Place stamp over component.

Software then seeks all components on

PCB matching this type.

5. Run program / adjust Filters until no false errors occur.

How A O I Works ~ STAMP Library

• Filter Settings

Visit the website www.smartgroup.org

A O I Types

Defect analysis example

A O I Type 1 ~ C orrelation

A O I Type 2 ~ Synthetic Imaging

A O I Type 3 ~ V ector Imaging

Moving from 2D to 3D Inspection

Typical Problems of 2D AOI

Lifted Pins/Leads

Flipped Components

Lifted Components

• The 100%“ solution of the problems listed above is to have accurate component height information.

2D 3D

Visit the website www.smartgroup.org

Moving from 2D to 3D Inspection

Pseudo 3D

(Side/Angled View Camera)

2D programming

High Components/Shadows

Local Information

Inspection Speed

(Lasers)

Very Local height information

Unsuitable for Solder

Joint Inspection

Inspection Speed

Real 3D with 2D overcomes most AOI issues

Shadow area Translucent surface Dark surface issue

Brightness

Real phase

Digitize

Error phase

2

1

0

4

3

6

5

Unwanted projection

Normal projection

Multiple reflections of projection

Multiple reflections

Normal projection

Unwanted projection

Multiple reflections of image acquisition

Brightness

Bright surface issue

Real phase

Saturation

Saturation level

Error phase

Position of stripe pattern

Position of stripe pattern

Visit the website www.smartgroup.org

Height Measurement Methods

Phase Measurement Profilometry

180deg phase

0deg phase

Phase round height

Base height

Brightness

One of raw images

Phase overlapped image

Phase difference

Position of stripe pattern

Illustration for imagination

Zero Reference Correction

The High End Systems calculate zero reference correction automatically for each height of the PCB and each FOV.

The correction is performed to calculate the average value of the points that have been recognized as the PCB surface in each FOV.

Automatic Zero

Reference Correction

Visit the website www.smartgroup.org

Defect Examples in 3D View

Tombstone Chip Component - 01005in.

232um Bad

Defect Examples in 3D View

Lifted Leads of IC Component

192um Good

922um

181um

Visit the website www.smartgroup.org

A O I Types

Which AOI machine matches your requirements?

Factors:

Which defects appear in my factory?

What is the required detection depth?

Large or small Batch sizes?

Is my process stable (False failure sensitivity)?

Is the an operator available for classification?

Is there a programmer available for programming?

What is my expected Pay-back time?

What is my investment/leasing budget

Visit the website www.smartgroup.org

Visit the website www.smartgroup.org