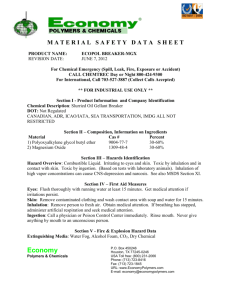

Table B2-2 Art - Metalworking

advertisement

Table B2-2 Control Measures - Metalworking ID Metalworking Technique Ingestion Hazard Inhalation Hazard 1 WELDING, BRAZING, & SOLDERING 2 Oxyacetylene Welding Fire Hazards 3 Oxyacetylene Welding Cylinder Precautions 4 Oxyacetylene Welding Safety Hazards Skin Contact Hazard Other Hazards Fire and explosion hazards Recommended Control Measures Welding surface should be fireproof, made of steel or firebrick; don't use asbestos sheeting; wooden floors & walls should be covered with fireproof materials; remove combustibles/flammables; don't weld on containers that have held combustibles/flammables Don't move cylinders w/out valve protection cap; make sure hoses can't be tripped over/don't contact grease; make sure connections are gas tight; use proper tools to open valves away from self-purge lines to remove mixed gases; close valves before relighting Thermal burns B2-2-1 Hot metal, flying sparks, infrared radiation can cause severe thermal burns on exposed skin Wear leather gloves, longsleeve 100% wool or flameretardant cotton shirts, pants, leather apron to protect from burns; don't wear flammable clothing Table B2-2, continued ID Metalworking Technique Ingestion Hazard Inhalation Hazard Skin Contact Hazard Other Hazards Recommended Control Measures w/cuffs, pockets; wear hightop leather boots w/out rubber/crepe soles & do have safety toes 5 Oxyacetylene Welding Health Hazards 6 Arc Welding Safety Hazards 7 Arc Welding Health Hazards Phosgene extremely toxic; carbon dioxide, acetylene cut off oxygen to lungs; carbon monoxide & fluoride flux fumes highly toxic; metal fume fever; metal dusts irritating; metal fumes highly toxic Ozone highly toxic/causes lung irritation/congestion/ chemical UV can cause skin cancer, eye damage, sunburn; can react w/ chlorinated hydrocarbons to form phosgene Eye damage from uv light B2-2-2 Visible light can cause eye strain/headaches; infrared radiation can cause skin burns/ chronic eye inflammation/ heat cataracts; copper/ zinc/ iron/ nickel/ magnesium can cause metal fume fever; lead/ cadmium/ manganese/ chromium/ beryllium/ nickel highly toxic Wear welding goggles w/shade #4-8; don't store chlorinated hydrocarbons where UV light can reach; know composition of metals/rods; use dilution ventilation of at least 2,000 cubic feet/minute/welder; use local exhaust system, NIOSH-approved respirator Increased risk of fire, thermal burns from sparks, heat stress; high risk of electric shock due to large electric currents used Wear protective clothing/leather leggings/sleeves; prevent fire; install & ground electric arc welders according to manufacturer; cables/ connectors should be of proper size, regularly inspected, & properly secured; inspect electrode holders, cables Chromates may cause lung irritation, allergies, nasal Use fireproof UV radiation screens around welding units; coat walls w/zinc Table B2-2, continued ID Metalworking Technique Ingestion Hazard Inhalation Hazard Skin Contact Hazard pneumonia/chronic bronchitis, can be fatal; nitrogen dioxide highly toxic/causes chemical pneumonia, emphysema; metal fumes/manganese/fluoride fumes highly toxic 8 FOUNDRY 9 Mold Making High-silica sands, silica flour, investment plasters highly toxic (can cause silicosis); formaldehyde extremely toxic; isocyanates highly toxic; asbestos extremely toxic; ethyl silicate highly toxic 10 Burnout of the Pattern Carbon monoxide highly toxic; wax decomposition fumes highly irritating; styrene, hydrogen cyanide gases highly toxic 11 Melting the Metal Carbon dioxide & carbon monoxide (highly toxic) from furnace; lead fumes from lead metal & bronze highly toxic; zinc fumes from bronze & brass moderately toxic; nickel Formaldehyde moderately toxic; hexamethylenetetramine causes skin irritation by decomposing to formaldehyde Other Hazards Recommended Control Measures septum ulceration, lung cancer; plasma arc welders produce much higher concentrations of ozone, nitrogen dioxide, metal fumes & produce high noise levels oxide to reduce reflection; leave 20 inches at bottom of screen for ventilation; wear welding helmet over impact-resistant flash goggles (#10-14); use local exhaust ventilation Formaldehyde known carcinogen; asbestos can cause lung cancer, mesothelioma, stomach/intestinal cancer; french chalk can contain high amounts of free silica Use foundry sand for molds, not high-silica sands; use local exhaust ventilation when mixing silica, or use NIOSHapproved respirator; avoid formaldehyde/polyurethane resins; wear gloves, goggles; DO NOT use asbestos/silica flour/French chalk; use graphite Ventilate with local exhaust system (canopy hood over burnout furnace) Natural gas/propane gas cause fire/explosion hazards; nickel fumes/dusts can cause lung/nasal cancer; using alloys B2-2-3 Gas furnaces should be connected by gas company; use alloys of known composition only; avoid nickel/lead; use local exhaust ventilation; wear infrared goggles, face Table B2-2, continued ID Metalworking Technique Ingestion Hazard Inhalation Hazard Skin Contact Hazard fumes may be extremely toxic (nickel carbonyl can be in it) 12 Pouring the Metal Hazardous metal fumes released during pouring; thermal decomposition of organic materials release formaldehyde, carbon monoxide, acrolein, cancer-causing substances; polyurethane foam can release hydrogen cyanide gas (extremely toxic) 13 Removing the Mold Intense temperatures convert normal quartz sand to highly hazardous. silica; sandblasting can cause silicosis in a few years exposure 14 FORGING & METAL FABRICATION 15 Cutting, Piercing, & Molten metal splashes can cause severe thermal burns Small metal filings can damage skin, eyes; B2-2-4 Other Hazards Recommended Control Measures of unknown composition can result in exposure to other toxic metals; furnace can cause heat stress; infrared radiation causes skin burns shield, long-sleeve wool shirt, insulated leggings, jacket, apron, gloves Manual pours limited by weight of crucible & person's strength; molten metal splashes on cement result in heat vaporizing water in cement, causing it to violently break apart in steam explosion Make sure you can lift crucible; don't pour by yourself; use two-person shank and ring/mechanical lifting equipment; embed molds in damp sand 18 inches deep, enclosed in metal; foundry floor should have raised metal grate/covered w/sand; use canopy hood Abrasive blasting creates loud amounts of noise, which can cause hearing loss Wear NIOSH-approved toxic dust respirator; vacuum/wet mop; don't use sand for abrasive blasting; use alumina/silicon carbide/walnut shells; avoid foundry slags w/arsenic; inspect blasting machine often; wear hearing protection, protective clothing; blasting hood Electric drills can cause electric Wear ANSI-approved goggles to protect eyes Table B2-2, continued ID Metalworking Technique Ingestion Hazard Inhalation Hazard Filing Metals 16 Forging Furnaces for hot forging give off large amounts of carbon monoxide and other highly toxic fumes & gases 17 Annealing 18 SURFACE TREATMENT OF METALS 19 Mechanical Treatment Benzine (VM&P naphtha) moderately toxic Skin Contact Hazard Other Hazards Recommended Control Measures saws, drills, metal snips can cause cuts shocks if they're not properly grounded against flying metal pieces/filings; make sure electrical equipment properly grounded & wiring is in good condition; handle tools w/sharp edges carefully; fasten metal piece in vise; put tools away after use Careless handling of hot objects can cause thermal burns; furnaces produce infrared radiation, which is an eye & skin hazard Noise is a hearing hazard in both hot/cold forging; large amounts of heat from furnaces can cause heat stress Do forging in separate room; wear ear plugs/ear muffs; equip all furnaces w/chimneys/canopy hoods; use exhaust fan; wear protective goggles (shade # 1.7-3.0); wear long-sleeve, cotton shirt, leather gloves, safety shoes, face shield; keep room cool Sulfuric acid/other acids & Sparex highly corrosive to skin, eyes; diluted acid less hazardous., but can cause burns Use of torches involves flammable gases, such as propane & acetylene, and oxygen/compressed air (fire & explosion hazards); furnaces can cause heat stress Use precautions w/gas torches, fuel-fired furnaces; wear protective goggles, gloves, apron; add acid to water; use Sparex; avoid acids; if acid splashes on skin, rinse w/water, if in eyes, rinse for 15-20 minutes; neutralize acid w/sodium bicarbonate Benzine moderately toxic; hot pitch is skin irritant & frequent, Heating pitch & use of benzine to remove pitch from Don't smoke/have open flames; store solvents in safety cans, store rags in B2-2-5 Table B2-2, continued ID Metalworking Technique Ingestion Hazard Inhalation Hazard Skin Contact Hazard Other Hazards Recommended Control Measures prolonged contact can cause skin cancer the metal creates fire hazards; engraving tools can cause cuts if used improperly disposal cans & remove each day; use adequate exhaust system; use gloves when handling hot pitch or benzine; handle engraving tools carefully; cut away from yourself Methyl cellosolve acetate can cause adverse reproductive effects, kidney damage, anemia; methyl cellosolve acetate & xylene flammable; carbon arcs emit ultraviolet radiation, which cause sunburn, eye damage; hot pitch is fire hazard. Wear gloves, goggles, protective apron, NIOSHapproved organic vapor respirator; add acid to water; if acid splashes on skin, rinse w/water, if in eyes, rinse for 15-20 minutes; use local exhaust system; use commercial resists; don't use carbon arcs 20 Etching & Photoetching Nitrogen dioxide gas highly toxic, causing pulmonary edema, pneumonia, emphysema; methyl cellosolve acetate highly toxic; xylene highly toxic; carbon arcs give off nitrogen oxides, ozone, metal fumes (highly toxic) Nitric acid/other acids highly corrosive to eyes, skin; methyl cellosolve acetate highly toxic; xylene moderately toxic; hot pitch can cause burns 21 Electroplating & Electroforming Sulfuric acid is respiratory irritant; lacquer vapors & mists highly toxic Risk of electrical shock; caustic soda, sulfuric acid highly corrosive; sulfuric acid skin & eye irritant; lacquer vapors moderately irritating 22 Electroplating & Electroforming Send pieces to commercial electroplater; wear rubber gloves, goggles, protective apron, NIOSH-approved respirator, rubber-soled shoes; add acid to water; if acid splashes on skin, rinse w/water, if in eyes, rinse 1520 min.; use local exhaust system Install ground fault circuit interrupter; install electroplating unit on B2-2-6 Table B2-2, continued ID Metalworking Technique Ingestion Hazard Inhalation Hazard Skin Contact Hazard Other Hazards (continued) Recommended Control Measures wooden/non-conducting surface, not on metal; don't use metal chair; don't touch bath, wires, electrodes w/bare hands; unplug power before adjusting bath; use special rectifiers/tape 23 Anodizing Hydrofluoric acid can be fatal Trisodium phosphate alkaline & can cause respiratory irritation; hydrofluoric acid highly corrosive to lungs Trisodium phosphate alkaline & can cause skin, eye irritation; hydrofluoric acid highly corrosive Titanium & tantalum are combustible; their filings & dust will burn; burns can occur without pain hours after exposure to hydrofluoric acid; hydrofluoric acid can cause chemical pneumonia, chronic bone/teeth or kidney damage; risk of electrical shock Wear insulating rubber gloves, goggles, protective apron, face shield; AVOID hydrofluoric acid, use wet sand & emery paper; only use hydrofluoric acid in lab hood or w/acid gas respirator; if contact w/skin/eyes, flush for 15 min. & call doctor right away 24 Patinas Patinas highly poisonous; concentrated acids highly corrosive; benzine moderately toxic Chlorinated solvents highly toxic; patinas highly poisonous; spray mists hazardous.; concentrated acids highly corrosive; potassium cyanide forms poisonous hydrogen cyanide gas; benzine moderately toxic, lacquers highly toxic Chlorinated solvents can be absorbed through skin; patinas corrosive; concentrated acids highly corrosive; benzine, lacquers moderately toxic Chlorinated solvents probable carcinogens; if heated w/torch, decompose to poisonous phosgene gas; diluted acids cause skin, eye irritation; oxidizing agents can cause fires/explosions; benzine, lacquer solutions flammable Use mineral spirits/detergent solutions to clean/degrease metals; don't use antimony/ arsenic/ cyanide/ mercury; wear goggles, gloves, protective apron; don't add acids to sulfides when coloring; store oxidizing agents away from solvents B2-2-7 Table B2-2, continued ID Metalworking Technique Ingestion Hazard Inhalation Hazard 25 Patinas (continued) 26 Niello Lead sulfide dust from grinding highly toxic Lead fumes emitted from melting of lead highly toxic; lead sulfide dust from grinding highly toxic 27 Gilding Mercury metal poorly absorbed Mercury metal highly toxic Skin Contact Hazard Other Hazards Recommended Control Measures Use glove box, local exhaust ventilation, NIOSHapproved toxic dust respirator; don't eat, drink, smoke in studio; dip/brush patinas instead of spraying; don't have smoke/open flames in working area; dispose of waste solvents & rags daily Do all melting & heating in local exhaust system; wear NIOSH-approved respirator; don't eat, drink, smoke in studio; wash hands carefully after work; wet mop surfaces; heat ammonium chloride paste inside a hood Mercury metal highly toxic B2-2-8 Acute mercury poisoning is accompanied by metallic taste, excessive salivation, swelling of gums/mouth, vomiting, bloody diarrhea, kidney failure, bronchitis, pneumonia; chronic mercury poisoning affects central nervous system DO NOT USE mercury amalgams; store mercury under water in closed containers; if mercury used, make amalgam on tray to contain spills; use local exhaust ventilation; clean up spills w/mercury spill kit; wash contaminated surfaces w/ferric chloride Table B2-2, continued ID Metalworking Technique Ingestion Hazard 28 CLEANING, POLISHING, & FINISHING 29 Pickling Ammonium bifluoride highly toxic 30 Grinding, Polishing, & Other Mechanical Techniques Leadcontaining dusts highly toxic Inhalation Hazard Recommended Control Measures Skin Contact Hazard Other Hazards Nitric & sulfuric acids highly toxic; hydrofluoric acid highly corrosive; potassium dichromate highly toxic Nitric & sulfuric acid, ammonium bifluoride highly toxic; hydrofluoric acid highly corrosive; sodium bisulfate moderately corrosive; potassium dichromate moderately toxic Boiling acid solutions can be very hazardous due to danger of splashing; dichromates are probable carcinogens; hydrofluoric acid can cause lung irritation, chemical pneumonia, chronic bone/teeth/kidney damage; may be fatal Wear gloves, goggles, protective apron, respirator, face shield; if acid splashes on skin, rinse w/water; if in eyes, rinse for 15-20 min.; cover acid baths; use local exhaust ventilation; use bifluoride pastes; neutralize acid w/sodium bicarbonate Lead-containing dusts highly toxic; free silica highly toxic, causing silicosis; formaldehyde highly irritating; silicacontaining abrasives may cause silicosis from chronic inhalation Cutting fluids may cause dermatitis Flying metal particles can cause eye damage; synthetic, semisynthetic, soluble cutting oils contain nitrosamines, which cause cancer in animals Wear goggles, face shield, respirator; grinding wheels should have eye shields; don't wear loose clothing; don't use sandstone wheels; use silicon carbide/alumina; use wet techniques; use local exhaust ventilation; use cutting oils w/out amines/nitrites B2-2-9