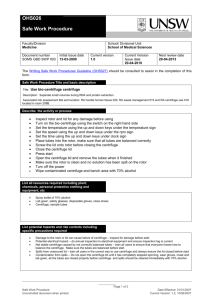

04_SWP_Centrifuge Use_AK

advertisement

OHS026 Safe Work Procedure Faculty/Division Medicine Document number SOMS.CGM.SWP004 Initial Issue date 12 June 2009 School/ Divisional Unit School of Medical Sciences Oncology Research Unit/Neuromuscular and Regenerative Medicine Unit Current version Current Version Next review date 1 12 June 2012 Issue date: 12 June 2009 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Title: Centrifuge Use Description: Safe use of centrifuges (excludes Ultracentrifuges) Associated risk assessment title and location: 04_RA_Centrifuge Use_AK Describe the activity or process Laboratory centrifuges: An apparatus used in the laboratory for separating substances of different density or particle size, when suspended in a fluid, by spinning them about an axis in a suitable container. Operation Only suitably trained persons may operate a centrifuge. Before use, the rotor, its lid and seals must be examined for cleanliness and damage (a build-up of chemicals from spillages may cause a tube to jam in the rotor or cause corrosion that could lead to a rotor failure). Damaged rotors must not be used and should be reported to the Lab Manager, dirty rotors must be cleaned by the approved method. (see rotor care). Never fill centrifuge tubes above the maximum recommended by the manufacturer. Check the minimum safe volume for the rotor, tube and speed of centrifugation from the manufacturers. Always use tubes that are specifically designed to be used in centrifuges and never centrifuge above the manufacturers recommended speed. Never exceed the maximum stated speed for any rotor. Balance the rotor to within the limits specified (take care that materials of similar densities are in opposite positions of the rotor). The higher the speed the rotor needs to be balanced more precisely, ie weigh centrifuge tubes plus contents on a scale. Do not operate the centrifuge without the appropriate rotor cover securely fitted and its seals in place. Check compatibility of tube material to solvent medium. (some solvents may cause the tubes to swell or crack in the rotor) Use only correctly fitting tubes. Clean up spillages immediately. Use appropriate PPE if necessary. Do not use chemicals that are explosive, highly flammable or have vigorous chemical interaction without observing the appropriate safety precautions to minimise risk of vapour build-up. Never attempt to open the lid of a centrifuge or slow the rotor by hand or open the lid while rotor is in motion as serious injuries may be incurred. Only authorised and suitably trained persons may service or repair a centrifuge, report all faults promptly, do not attempt repairs yourself. Do not use the centrifuge until the fault has been inspected or repaired. Rotor Care Stress corrosion is thought to be initiated by certain combinations of stress and chemical reaction. If the rotor is not kept clean and chemicals remain on the rotor, corrosion will result. Also, any moisture left for an extended time can initiate corrosion. It is important that the rotor is left clean and dry. (Wash with mild detergent and warm water). Dry the rotor thoroughly and store upside down with the cover and tubes removed. Do not expose aluminum rotor components to strong acids or bases, alkaline lab detergents or salts ___________________________________________________________________________________________________________ ___________ Page 1 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 (chlorides) of heavy metals (e.g. caesium, lead, silver or mercury.) Use of these can initiate corrosion. List all resources required including plant, chemicals, personal protective clothing and equipment, etc Materials and Equipment Eppendorf Centrifuge 5424 Eppendorf Centrifuge 5810 Eppendorf Centrifuge 5414R QikSpin Centrifuge Personal Protective Clothing and Equipment Laboratory coat/gown Gloves Mask (if possibility of aerosols) List potential hazards and risk controls including specific precautions required 1) Physical Injury due to spinning rotor Risk Controls: proper training, proper and regular maintenance; do not exceed maximum speed stated for rotor and centrifuge, never fill centrifuge tubes above the maximum recommended by the manufacturer, balance the rotor to within the limits specified, maintain rotors in good condition. 2) Infections from aerosols Risk Controls: proper training, proper and regular maintenance; do not exceed maximum speed stated for rotor and centrifuge, never fill centrifuge tubes above the maximum recommended by the manufacturer, balance the rotor to within the limits specified, maintain rotors in good condition, clean up spillages immediately 3) Potential electrical hazard Risk Controls: annual inspection of electrical equipment and ensure inspection tag is current. List emergency shutdown instructions For centrifuges, turnoff at power point. If unable or unsafe to do so use the emergency cutoff switch (red button) for the laboratory (Rm 502) located on the wall near the entrance to the lab. List clean up and waste disposal requirements If rotor or centrifuge becomes contaminated wash with mild detergent, warm water and then 70% ethanol. Dry the rotor thoroughly after washing. List legislation, standards and codes of practice used in the development of the SWP NSW OHS Act 2000 NSW OHS Regulation 2001 Code of Practice for the Labelling of Workplace Substances AS/NZS 2243.2:2006. Safety in laboratories. Part 2: Chemical aspects AS/NZS 2243.3: 2006 Safety in laboratories Part 3: Microbiological aspects and containment facilities AS/NZS 2243.6-1990. Safety in laboratories. Part 6: Mechanical Aspects. AS/NZS 2243.3:2006 Safety in Laboratories Part 7 Electrical aspects AS/NZS 2161.1:2000 Occupational Protective Gloves – Selection, Use and Maintenance Safe Work Procedure Form (OHS026) Supervisory approval, training, and review Supervisor: Edna Hardeman Signature: Plant custodian: Signature List competency required – qualifications, certificates, licencing, training - eg course or instruction: Training as per the Training Needs Analysis, Induction to Lab, training in this SWP ___________________________________________________________________________________________________________ ___________ Page 2 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 ___________________________________________________________________________________________________________ ___________ Page 3 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007