Musterbrief sw - Muller Martini

advertisement

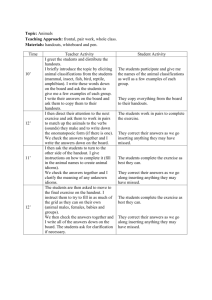

Muller Martini Marketing AG Press Release Date No. Number of characters Contact 16.10.2014 PI 1880 3424 Muller Martini Marketing AG Untere Brühlstrasse 13, 4800 Zofingen, Switzerland Tel. +41 (0)62 745 45 75, Fax +41 (0)62 751 55 50 info@mullermartini.com, www.mullermartini.com Media Group Münchner Merkur tz Invests in New Mailroom Inserting, Stitching and Trimming Inline The Münchner Merkur tz media group is investing in its second complete newspaper mailroom system from Muller Martini within a short period of time. Following its new printing plant in Penzberg, the group’s main plant on Dessauerstrasse in Munich is next in line to be equipped with a ProLiner inserting system featuring a CoLiner pre-gatherer. The ProStitch stitching unit, which is integrated into the ProLiner, together with the NewsTrim fanflex trimmer, enables inserting, stitching and trimming to be performed inline. In addition to various daily newspapers, including the flagship Münchner Merkur, the Münchner Merkur media Group also prints several weekly newspaper at its main plant in Dessauerstrasse in Munich, including the Bayerisches Landwirtschaftliches Wochenblatt. The traditional agricultural weekly is produced in a print run of around 110,000 copies in a wire-stitched tabloid format and regularly contains inserts. The Bayerisches Landwirtschaftliches Wochenblatt is currently produced using a relatively old saddle stitcher 300 with a Biliner inserting system from Muller Martini. The new solution will make the production of the Münchner Merkur media group far more cost-effective. The group opted for a new ProLiner inserting system with an integrated ProStitch stitching unit and a NewsTrim fanflex trimmer, to which the finished products are conveyed directly from the ProLiner. That means the agricultural weekly can be produced in a single production process, which, according to Managing Director Uwe Günther, was one of the main reasons that the Münchner Merkur media group chose this solution. Muller Martini is the only supplier of mailroom systems that enable inserting, stitching and trimming to be performed inline in a single pass. NewsLiner Extension In addition to the new ProLiner inserting system with three automatic preprinted section feeders, five feeders, coupled with a CoLiner pre-gatherer with four feeders and stream feeders for automatic insert feeding, three NewsStack compensating stackers with TABA F top sheet applicator, the Mailroom Production Control (MPC) addressing, ramp and control 1/2 Muller Martini Marketing AG system with Connex.Info from Connex.Mailroom and MMRemote Online (enabling remote access for diagnosis and corrective action), the Munich-based newspaper publisher has also decided to extend its existing NewsLiner inserting system from Muller Martini. A CoLiner with eight feeders will be docked on. The existing compensating stackers will be fitted with TABA F and a control system update for connection to MPC, and the NewsLiner will also be controllable from the Muller Martini factory in future by means of MMRemote Online. Second Major Investment The new systems will begin production in the second quarter of 2015. The Münchner Merkur tz media group, which is based in the Bavarian capital of Munich, is investing in its second newspaper mailroom system from Muller Martini within a short period of time. “We believe in the future of printed newspapers,” says Günther. The media group likewise chose a complete system from Muller Martini for its new printing center in Penzberg with two ProLiner newspaper inserting lines, each coupled with a CoLiner pre-gathering unit, and each with three NewsStack compensating stackers with TABA F, a NewsSorter ramp system and the MPC control system. Image caption PI 1880.jpg The ProStitch stitching unit, which is integrated into the ProLiner inserting system, together with the NewsTrim fanflex trimmer (pictured), enables inserting, stitching and trimming to be performed inline. 2/4

![[#EXASOL-1429] Possible error when inserting data into large tables](http://s3.studylib.net/store/data/005854961_1-9d34d5b0b79b862c601023238967ddff-300x300.png)