job title - Spiration

advertisement

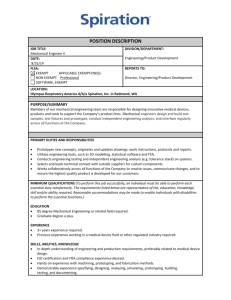

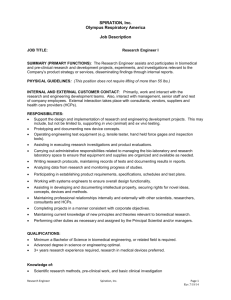

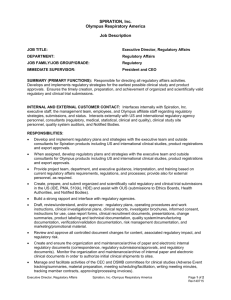

POSITION DESCRIPTION JOB TITLE: Senior Buyer/Planner DATE: 7/18/14 FLSA: EXEMPT APPLICABLE EXEMPTION(S): NON EXEMPT Professional SOFTWARE, EXEMPT DIVISION/DEPARTMENT: Manufacturing Operations REPORTS TO: Director, Operations LOCATION: Olympus Respiratory America d/b/a Spiration, Inc. in Redmond, WA PURPOSE/SUMMARY Conducts activities related to the sourcing, negotiating of contracts, procurement and control (i.e. receiving, movement and transactions, shipping, etc.) of materials, equipment and manufacturing-associated services at Spiration. Is responsible for selecting, reviewing and evaluating suppliers and developing partnerships with key vendors. Solicits bids and awards contracts for a wide variety of capital, technical and non-technical items and materials within written Spiration guidelines, Olympus Corporation of the America’s (OCA’s) policies and applicable regulations. Provides guidance and training to internal departments concerning purchasing processes and procedures. PRIMARY DUTIES AND RESPONSIBILITIES Identifies sources, initiates and negotiates contracts, selects vendors and executes Purchase Orders (POs) for equipment, raw materials, assemblies, construction and manufacturing-associated services and evaluates quotations, bids and proposals. Negotiates adjustments with vendors involving replacement of equipment or materials not conforming to purchase specifications, cancellations/termination of contracts and/or POs and preparation of contract amendments and/or Document Change Notices (DCNs) as required. Reviews and edits requisitions, DCN’s, drawings/ specifications, requirements and recommends changes and/or substitutions if needed. Creates procurement schedules. Coordinates with Planning and Finance Department to establish goals for inventory levels and other financial targets. Participates in cross-functional efforts with Supplier Quality Management to select, review and continuously evaluate suppliers. Manages strategic supplier partnerships in order to achieve quality, delivery and cost objectives. Develops second source suppliers to reduce business risk. Participates in the planning and implementation of improvement systems (i.e. use of Kanbans, backflush, Demand Flow Technology (DFT), supply chain management strategies, etc.) to minimize WIP/working capital and cycle times, and maximize responsiveness to customer needs. Creates solutions to material availability and scheduling challenges resulting from unplanned events such as product failures, part shortages, sales increases beyond forecast and fluctuations in product yields. On an ad-hoc basis (as part of the back-up team): Performs duties required with receiving of freight and routing to appropriate areas; Ships products or materials requested by internal customers or HUD shipments; Supports the release of work orders, pulling materials and chemicals, cycle counts and inventory for physical year end. Adheres to general safety rules, manufacturing procedures, company policies and procedures, Good Manufacturing Practices, and FDA regulations. Performs other miscellaneous duties as requested or assigned. SUPERVISOR RESPONSIBILITIES (IF ANY) – Optional section None. MINIMUM QUALIFICATIONS (To perform this job successfully, an individual must be able to perform each essential duty satisfactorily. The requirements listed below are representative of the, education, knowledge, skill and/or ability required. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions.) EDUCATION B.S. or B.A. or equivalent required. Manufacturing or Supply Chain Management curriculum optimal. Evidence of continued learning efforts preferred. EXPERIENCE 8+ years related experience (material planning, supply change management, contract negotiation, etc.) within a highly regulated industry required (FDA, aerospace, military or similarly complex manufacturer). Class III medical device manufacturing company optimal. CERTIFICATIONS/LICENSES APICS certification(s) in Certified in Integrated Resource Management (CIRM) and Certified in Production and Inventory Management (CPIM) are desired. SKILLS, ABILITIES, KNOWLEDGE Proven sophisticated contract negotiation and relationship building skills required. Solid analytical and math skills also required. Six Sigma, LEAN or TQM experience preferred. Advanced computer skills including sophisticated Excel skills a must. Access, Visio, Powerpoint, MRP/inventory control/supply chain management software strongly preferred. Sophisticated skills in supply chain management and material planning a must. Must be highly and effectively organized. Must also be a flexible, self-starter, team-oriented, and capable of multi-tasking. Excellent written and verbal communication skills, ability to handle confidential and sensitive matters, and skillful at fostering collaborative relationships across all lines of the company. PHYSICAL DEMANDS Frequently Lift/Carry 25 lbs Microscope/Fine close work 8 hrs a day Vision requirements correctable to 20/20 vision WORK ENVIRONMENT Chemicals/Solvents Infectious Disease exposure Radiation Frequently Push/Pull 50+ lbs Bend/Stoop/Kneel 2 hrs a day Stand/Sit/Walk 8 hrs a day Dexterity required Operate moving vehicles Other Clean Room Laser ETO exposure Eye Protection Noise above 85 decibels Other Spiration d/b/a Olympus Respiratory America is an Equal Opportunity Employer P a g e |2 Sr. Buyer/Planner.140927