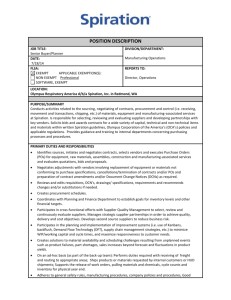

job title - Spiration

advertisement

POSITION DESCRIPTION JOB TITLE: Quality Engineer I, II or III (DOE) DATE: 9/25/14 FLSA: EXEMPT APPLICABLE EXEMPTION(S): NON EXEMPT Professional SOFTWARE, EXEMPT DIVISION/DEPARTMENT: Quality Systems REPORTS TO: Director, Quality Systems LOCATION: Olympus Respiratory America d/b/a Spiration, Inc. in Redmond, WA PURPOSE/SUMMARY The Quality Engineers support the development and manufacture of Spiration products during all phases of design, development, production, and distribution. All Quality Engineers, in one manner or another, are responsible for: Acting as the Quality Representative on the Product Development project teams Supplier management, including supplier qualification, audits, and annual reviews Inspection and test methods and systems Complaint handling and product investigations of device returns Corrective and preventive action Maintenance of Spiration quality management system by ensuring compliance to U.S. and international regulatory requirements for medical devices Internal quality audits. PRIMARY DUTIES AND RESPONSIBILITIES 1. Support design and development projects a. Represent the Quality team. Provide input and coordinate activities related to: Risk analysis activities (design and process FMEAs) Supplier sourcing, qualification, and selection Acceptance criteria and inspection methods of components and assemblies Product labeling and specifications b. Develop and maintain Design History File c. Provide project team with guidance on compliance to Product Development Process d. Assist in regulatory submissions, as required. 2. Supplier Management a. Supplier Management Team (SMT) member supporting the evaluation, risk analysis, qualification, approval and monitoring of Spiration suppliers b. Perform supplier audits, as required c. Conduct annual reviews of approved suppliers d. Issue and track Supplier Corrective Action Requests to closure e. Maintain Approved Supplier List. 3. Support and maintain device production and distribution activities a. Facilitate and continually improve complaint handling system. Perform and coordinate investigations of product returns in a timely manner. b. Review and approve release of or changes to specifications and drawings, evaluating design change impact, including effect on inspection, verification/validation, risk analysis, sterilization, and biocompatibility c. Identify areas requiring corrective and preventive action, including those resulting from nonconforming product. Coordinate activities associated with planning and implementing solutions. Follow up, as required, to ensure effective implementation d. Provide data collection, review, and analysis of processes supporting production and product quality. Communicate information effectively e. Quality representative for Material Review Board (MRB) activities. 2. Corrective and Preventive Action a. Assist in maintenance of CAPA Log or database and coordination of CAPA Review Board meetings b. Complete assigned CAPA actions c. Conduct and document verification of implementation and effectiveness of corrective and/or preventive actions 2. Support and participate in inspection and test activities. a. Review and approve inspection requirements b. Assist in inspection processes through development of inspection tools and aides; i.e., go/no go gages, visual standards, and reference samples c. Review and approve first article inspections d. Determine compliance to specifications. 3. Support Spiration quality management system a. Perform or assist in hosting internal audits according to approved schedule. b. Maintain SPC database and expand implementation, as needed. c. Create/revise SOPs and work instructions. 4. Sterilization and Biocompatibility a. Assist in coordinating the development of sterilization processes, validation, revalidation, and routine monitoring. b. Review sterilization test results for final product release. This includes, but is not limited to, EO residuals, sterility, and bacterial endotoxins (pyrogen). c. Assist in determining applicable biocompatibility requirements for US and international compliance. Coordinate biocompatibility testing with outside laboratories. 5. Trend analysis and data reporting for identified performance measures. MINIMUM QUALIFICATIONS (To perform this job successfully, an individual must be able to perform each essential duty satisfactorily. The requirements listed below are representative of the, education, knowledge, skill and/or ability required. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions.) EDUCATION BS degree in a technical discipline is required. Evidence of continued learning efforts a plus. P a g e |2 Quality Engineer II.140927 EXPERIENCE 2++ years in a medical device manufacturing environment. Previous Quality Engineering experience preferred. CERTIFICATIONS/LICENSES ASQC CQA and/or CQE preferred. SKILLS, ABILITIES, KNOWLEDGE Knowledge of ISO 13485, 21 CFR Part 820, 93/42/EEC Medical Devices Directive, SOR 98/282, Canadian Medical Device Regulations, 21 CFR Part 11, ISO 14971, ISO 11135, ISO 10993-1, ISO 11607 and other medical device industry US and international standards. Experience with risk analysis and reliability engineering techniques. Identifying requirements, setting realistic scheduling and meeting deadlines. Ability to identify issues, determine root cause, and implement solutions. Ensure compliance to standards, regulations and Company procedures. Identify and facilitate process and SOP improvements within the Quality System, embracing a culture of continuous improvement. Advanced Microsoft software skills including sophisticated Word, Excel and Powerpoint skills a must. Access, Visio, database and statistical analysis software experience optimal. Sophisticated written and verbal communication skills, including previous experience in procedure, protocol and report writing required. Must be highly and effectively organized as well as a flexible self-starter, team-oriented, and excellent at prioritization and multitasking. A natural at fostering collaborative relationships across all lines of the Company. PHYSICAL DEMANDS Frequently Lift/Carry up to 25 lbs Microscope/Fine close work 8 hrs a day Vision requirements correctable to 20/20 vision WORK ENVIRONMENT Chemicals/Solvents Infectious Disease exposure Radiation Frequently Push/Pull 50+ lbs Bend/Stoop/Kneel 2 hrs a day Stand/Sit/Walk 8 hrs a day Dexterity required Operate moving vehicles Other Clean Room Laser ETO exposure Eye Protection Noise above 85 decibels Other Spiration d/b/a Olympus Respiratory America is an Equal Opportunity Employer P a g e |3 Quality Engineer II.140927