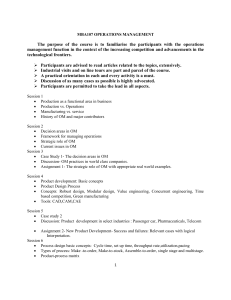

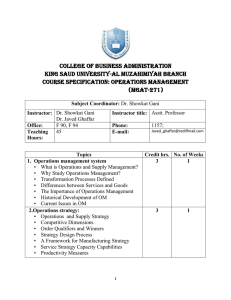

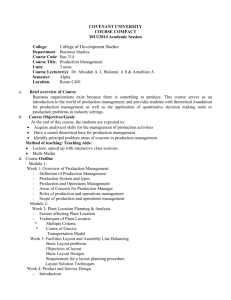

1 Intro to OM

advertisement

OPERATIONS MANAGEMENT OPERATIONS AND PRODUCTIVITY LECTURE 1 (CHAPTER 1) WHAT IS OPERATIONS MANAGEMENT? Production is the creation of goods and services Operations Management - management of the set of activities that creates value in the form of goods and services by transforming inputs into outputs Applies to both manufacturing and service organizations 2 ORGANIZATIONAL FUNCTIONS Marketing Gets customers Operations creates product or service Finance/Accounting Obtains funds Tracks money 3 FUNCTIONS - BANK Commercial Bank Marketing Teller Scheduling Operations Check Clearing Transactions Processing Finance/ Accounting Security 4 FUNCTIONS - AIRLINES Airlines Marketing Flight Operations Operations Ground Support Facility Maintenance Finance/ Accounting Catering 5 FUNCTIONS - MANUFACTURING Manufacturing Marketing Manufacturing Operations Production Control Quality Control Finance/ Accounting Purchasing 6 WHY STUDY OM? OM is one of three major functions (marketing, finance, and operations) of any organization To know how goods and services are produced/delivered To understand what operations managers do OM is a costly part of an organization OM presents interesting career opportunities e.g. SCM, QA, Process Re-engineering, etc 7 TEN CRITICAL DECISIONS Service, product design ……. Quality Management ……… Process, capacity design …... Location ….……………….... Layout design ………..…….. Human resources, job design.. Supply-chain management … Inventory management ….…. Scheduling .………………… Maintenance .………………. Ch. 4 Ch. 5, 5S Ch. 6, 6S Ch. 7 Ch. 8 Ch. 9, 9S Ch. 10,10s Ch. 11, 13, 15 Ch. 12, 14 9 TEN CRITICAL DECISIONS Service and product design What product or service should we offer? How should we design these products and services? Quality management How do we define quality? Who is responsible for quality? 10 TEN CRITICAL DECISIONS - CONTINUED Process and capacity design What processes will these products require and in what order? What equipment and technology is necessary for these processes? Location Where should we put the facility On what criteria should we base this location decision? 11 TEN CRITICAL DECISIONS - CONTINUED Layout design How should we arrange the facility? How large a facility is required? Human resources and job design How do we provide a reasonable work environment? How much can we expect our employees to produce? 12 TEN CRITICAL DECISIONS - CONTINUED Supply chain management Should we make or buy this item? Who are our good suppliers and how many should we have? Inventory, material requirements planning, How much inventory of each item should we have? When do we re-order? 13 TEN CRITICAL DECISIONS - CONTINUED Intermediate, short term, and project scheduling Is subcontracting production a good idea? Are we better off keeping people on the payroll during slowdowns? Maintenance Who is responsible for maintenance? When do we do maintenance? 14 CHANGING CHALLENGES FOR THE OPERATIONS MANAGER Past Causes Future Local or national focus Batch (large) shipments Low-bid purchasing Lengthy product development Low-cost, reliable worldwide communication and transportation networks Cost of capital puts pressure on reducing investment in inventory Quality emphasis requires that suppliers be engaged in product improvement Shorter life cycles, rapid international communication, computer-aided design, and international collaboration Global Focus Just-in-time shipments SC partners, ERP Rapid product development, alliances, collaborative designs 15 CHANGING CHALLENGES FOR THE OPERATIONS MANAGER Past Standardized products Job specialization Low cost focus Causes Future Affluence and worldwide markets; increasingly flexible production processes Changing socio-cultural scene. Increasingly a knowledge and information society. Mass customization Environmental issues, ISO increasing disposal costs Environmentally sensitive production, Green manufacturing, Empowered employees, teams, 16 CHARACTERISTICS OF GOODS Tangible product Production usually separate from consumption Consistent product definition Low customer interaction Can be inventoried 17 CHARACTERISTICS OF SERVICE Intangible product (Intangibility) Produced & consumed at same time (simultaneity) Inconsistent product definition (Heterogeneity) High customer interaction Often unique Often knowledge-based Frequently dispersed 18 GOODS CONTAIN SERVICES / SERVICES CONTAIN GOODS Automobile Computer Installed Carpeting Fast-food Meal Restaurant Meal Auto Repair Hospital Care Advertising Agency Investment Management Consulting Service Counseling 100 75 50 25 0 25 50 75 100 19 Percent of Product that is a Good Percent of Product that is a Service SERVICE/PRODUCT BUNDLE Element Core Goods Example Core Service Example Business Custom clothier Business hotel Core Business suits Accommodation Peripheral Goods Peripheral Service Garment bag Bath robe Deferred payment plans In house restaurant Variant Coffee lounge Airport shuttle THE SERVICE PACKAGE Supporting Facility: The physical resources that must be in place before a service can be sold. Examples are golf course, hospital, hotel. Facilitating Goods: The material consumed by the buyer or items provided by the consumer. Examples are food items, legal documents, golf clubs, medical history. Information: Operations data or information to enable efficient and customized service. Examples are patient medical records, seats available on a flight, customer preferences, location of customer to dispatch a taxi. THE SERVICE PACKAGE (CONT.) Explicit Services: Benefits readily observable by the senses. The essential or intrinsic features. Examples are absence of illness after treatment, smoothly running vehicle after tune up, on-time departure. Implicit Services: Psychological benefits or extrinsic features which the consumer may sense only vaguely. Examples are privacy of loan office, security of a well lighted parking lot, staff courtesy. PRODUCTIVITY Measure of process improvement Represents ratio of output to input Productivity Units produced = Input used Only through productivity increases can our standard of living improve 23 MULTI-FACTOR PRODUCTIVITY Productivity = Output Labor + material + capital + energy + Misc 24 MEASUREMENT PROBLEMS Quality may change while the quantity of inputs and outputs remains constant External elements may cause an increase or decrease in productivity Precise units of measure may be lacking 25 SERVICE PRODUCTIVITY Reasons for low productivity in services Frequently Often individually processed an intellectual task performed by professionals hence often difficult to mechanize Growth of low productivity activities e.g. food preparation, laundry, house cleaning 26 TACO BELL - IMPROVING SERVICE PRODUCTIVITY Revision of menu to include meals that are easy to prepare Substantial portion of food preparation shifted to suppliers e.g. pre-cooking, predicing, etc Efficient design of layout and automation of operations Training and empowerment of management to increase competence – reduce labor 27