Literature Review: A Framework of SCM

advertisement

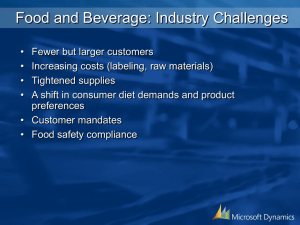

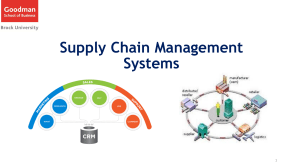

Introduction of supply chain management Presented By: Eng . Sameh Said Agenda • Introduction of operation management. • Operation management (definition and solution role). • Definition of supply chain management. • Problem face allocation of supply chain. • Integration of supply chain in organization. Definition of Operation Management Operations management (OM) is the business function that plans, organizes, coordinates, and controls the resources needed to produce a company’s goods and services. Defined the role of operation management? The role of operations management is to transform a company’s inputs into the finished goods or services DIFFERENCES BETWEEN MANUFACTURING AND SERVICE ORGANIZATIONS. Historical Development of Operations Management 1700 Industrial Revolution Change production to use machine power instead of human power 1900-1960 Scientific Management - Management science (improve techniques to solve operation problem) - Human relation focus (role of human element in job design) - Computer (processing a large amount of data) 1980-1995 TQM&JIT Technique Supply Chain Management E- Commerce Operation Management Across The Organization Defining Supply Chain - The systemic, strategic coordination of the traditional business functions and the tactics across these business functions. Information Supplier Product Funds Customer Supply chain refers to the flow of materials, information, payments, and services from raw material suppliers, through factories and warehouses (Value Chain), to the final consumer (Demand Chain). It includes tasks such as purchasing, payment flow, materials handling, production planning & control, logistics & warehousing, inventory control, and distribution. When it is managed electronically it is referred to as an e-supply chain. The objective of applying supply chain Objective is to be able to have the right products in the right quantities (at the right place) at the right moment at minimal cost Supply Chain Management (SCM) To plan, organize, coordinate and optimize all the supply chain’s activities Supply chain problem The bullwhip effect refers to erratic shifts in orders up and down the supply chain because of poor demand forecasting or variation of order size. Causes - Little or no communication between supply chain partners - Delay times between order processing, demand, and receipt of products Uncertainties exist in delivery times – – – Machine failures Road conditions Shipments Order Size The Dynamic solution of the Supply Chain Customer Demand Distributor Orders Retailer Orders Production Plan Time Order Size What Management Gets... Customer Demand Production Plan Time Volumes What Management Wants… Production Plan Customer Demand Time Supply Chain Solutions Information sharing among supply chain partners (c-commerce) sometimes referred to as the collaboration supply chain is one method to overcome problems in the flow. Others are: • Optimal Inventory Levels • Supply Chain Coordination and Collaboration • Supply Chain Teams • Performance Measurement and Metrics • Various IT-Assisted Solutions – wireless technology – optimal shipping plans – strategic partnerships with suppliers – just-in-time Essentials of the Supply Chains Reduce uncertainty (demand forecast-delivery time)and risks in the supply chain positively affecting inventory levels, cycle time, business processes, and customer service Increase profitability and competitiveness Integration of supply chain management Business Impact Best Practice Plan Management Focus - Plan a Strategy for managing all the resources that go toward meeting customer demand for the product or service which is depend on the type of organization and nature of products. A Framework for Structuring Drivers Efficiency Responsiveness Supply chain structure Facilities Transportation Inventory Drivers Information Integration of supply chain management is continued Business Impact Best Practice Source Plan Management Focus Source - Choose the suppliers that will deliver the goods and services to create the product or service. Develop a set of pricing, delivery and payment processes with suppliers and create metrics for monitoring and improving the relationships Integration of supply chain management is continued Best Practice Business Impact Make Source Plan Management Focus Make - This is the manufacturing step. Schedule the activities necessary for production, testing, packaging and preparation for delivery optimization knowhow of planning, schedule and sequencing which is mean productivity optimization Integration of supply chain management is continued Best Practice Business Impact Deliver Make Source Plan Management Focus Deliver - Coordinate the receipt of orders from customers, develop a network of warehouses, pick carriers to get products to customers and set up an invoicing system to receive payments Integration of supply chain management is continued Current Best Practice Return Business Impact Deliver Make source Plan Management Focus Return - Create a network for receiving defective and excess products back from customers and supporting customers who have problems with delivered products (product recall by batch)