Specification for sprayed open cell foam materials, 0615

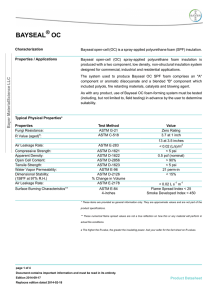

advertisement

ecoInsulateltd Unit 1, Laverockhall Farm Road, Lochmaben, Lockerbie, Dumfries and Galloway DG11 1RE e-mail: info@ecoinsulate.co.uk Tel: 01387 810709 www.ecoinsulate.co.uk SPECIFICATION FOR SPRAYED OPEN CELL FOAM INSULATION MATERIALS Application: For installation by spraying onto surfaces of building structures to insulate and prevent condensation on a wide range of applications including roofs, walls, floors and soffits. Material: Open cell spray polyurethane foam (SPF) system to BS EN 14315 with an open cell content of approx 60%. Applied in situ by spraying, following processing through standard two component equipment designed for this purpose. The product will be formaldehyde free, curing to a low density, soft, flexible and breathable material. The product will be water blown and free from formaldehyde HFC’s and PBDE’s. Cured foam to provide insulation and air seal in one application and hold CE Mark where applicable. Durability of the product is to have a life equivalent to that of the structure in which it is incorporated. Cured foam to provide insulation and air seal in one application and hold BBA accreditation and CE marking applicable to its use. Durability of the product is to have a life equivalent to that of the structure in which it is incorporated. The SPF supplier must be British Urethane Contractors Association (BUFCA) approved. Enertite material manufactured by BASF plc, Performance Materials Europe, Wimsey Way, Alfreton, Derbyshire DE55 4NL or equal and approved, supplied and installed by eco Insulate Ltd, Unit 1 Laverockhall Farm Road, Lochmaben, Lockerbie, DG11 1RE Tel: 01387 810709. Treatment: The SPF Installer shall be a member of BUFCA and adhere to their Code of Practice for Urethane Foam Contractors. Material application is to be in accordance with the manufacturer’s recommended instructions and independent accreditation where applicable. Work is to be carried out by a FoamMaster Approved Installer holding a current, signed and numbered certificate issued by the manufacturer. The Approved Installer will be responsible for each installation of the product they undertake. To comply with Health and Safety requirements it is essential that there is an exchange of information between the Client and installer prior to spray operations commencing on site. Building elements to be sprayed must be assessed for suitability, be clean (without dust or grease), dry and in the case of metallic substrates, free of rust.