ICAA Spray Foam Checkpoints

Spray Foam Insulation

Inspection Checklist

Spray foam insulation is used to insulate and air seal the building envelope. This Inspection Checklist is an outline to ensure that the product achieves or exceeds both insulation and air sealing standards as set forth by local code.

Wall Areas

1.

Cavity Fill — Foam is applied to a specified thickness and shall adhere to all sides of the cavity to ensure continuous insulation and air seal.

2. Plumbing — Foam shall be sprayed to encapsulate pipes.

3. R-value — An onsite certificate should indicate R-value and installed insulation thickness.

4. Vapor Retarder — Install as required by local building codes and manufacturers’ recommendations.

5. Electrical Boxes — Encapsulate with interior free of foam.

6. Bay Windows — The outside wall, extended floor, and ceiling must be sprayed.

7. Windows/Doors — Every open space around windows shall be insulated as approved by the window/door manufacturer.

8. Metal Studs — Metal studs should be checked for deformation.

Floor & Ceiling Areas

1.

Overhangs — The ceiling and floor areas shall be sprayed.

2. Attic Covers — Access openings from conditioned spaces to unconditioned spaces shall be insulated to a level equivalent to surrounding surfaces.

3. Eave Baffles — Baffles shall be installed on eaves with vents in attics that are conventionally vented.

4.

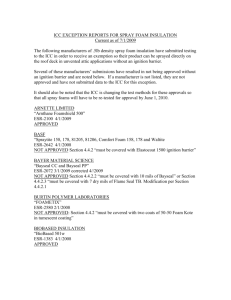

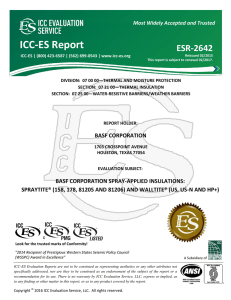

Attics and Crawl Spaces — Spray foam shall be applied in accordance with the International Code Council Evaluation

Service Report (ICC-ES) or legacy report.

General

1. Hot Surfaces — Keep insulation at least three inches away from hot surfaces, such as chimneys, non-IC fixtures, and heated flue pipes. Follow manufacturers’ recommendations for application to IC-rated recessed light fixtures.

2. Unconditioned Rooms — The walls, ceilings, and floors between conditioned space and unconditioned areas shall be insulated.

3. Thermal Barrier — Unless spray foam has been approved for exposed application, spray foam shall be protected from adjacent occupied spaces by an approved thermal barrier.

4. Tub Enclosures — Insulation shall be installed between tub enclosures and outside walls.

5. Repair — If a repair to the foam is required, polyurethane repair kits may be used.

6. Rated Wall Assemblies — Approved fire resistant rated wall assemblies shall be defined in manufacturers’

ICC-ES reports.

Alternate Method

1. Energy Analysis — Code approval shall be based on Energy Performance Analysis which includes air infiltration as performance factor.

2. Comments — If material meets air barrier criteria in accordance with ASTM E283 or ASTM E2178, the material need not be in contact with the pressure boundary (vapor retarder or drywall depending on climate zone) on all six sides.

This Checklist is provided as a convenience for informational purposes only.

Spray foam insulation materials should meet the requirements of applicable local codes and standards. Please consult manufacturers’ recommendations and local building codes and building code officials for specific requirements.

ICAA and/or its members are not responsible for any loss, damages, and/or claims caused by errors or omissions or any other cause.

Copyright © Insulation Contractors

Association of America 2008