R-Value overemphasized article

advertisement

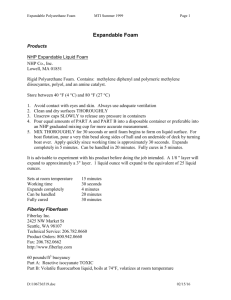

R Value is overemphasized in sizing insulation. Being in the construction industry and working with trades and skilled craftsman in residential, industrial and commercial disciplines, we find that all structures are dependent on the application of mathematical principles and design concepts that have proven the tests of time. These structures could be the homes we live in, the schools our children attend or the multi-story office buildings where we earn our livings. All of them are built according to performance based design criteria and are in conformance with our Municipality’s local building codes. These codes are there for the protection of the owner and the occupants of that structure to insure that proven principles and materials are used in their projects construction to meet said specification standards. One of the key components, the building’s insulation, uses a substandard antiquated method of evaluating or sizing the performance of a structure to keep it warm or cool. This method or process is based on a measurement labeled R value, which is a measurement of resistance to conductive heat energy. The test for R value specifications is generally performed in a controlled environment called a vacuum tube where there is no measurement for air movement or convection being taken into consideration. Air movement or convection is responsible for up to 50% of your home or residence’s heat loss/gain in a non-laboratory or field environment. Unfortunately, we don’t live in a vacuum tube…so how valuable is it to have your home’s insulation tested in one? R-value is only responsible for about 30% of a homes insulation performance…that’s right, just 30%. Convection is 40-50% and Radiation from the sun is responsible for up to 20-25% of your building’s insulation performance. So wouldn’t it make more sense to test insulation’s ability to resist air movement, since this makes up for almost 50% of the products performance? Enter Polyurethane Spray foam insulation…When sprayed in accordance with manufacturer’s recommendations and local building code requirements, spray foam insulation seals out incoming and outgoing air to save 40-50% on heating and cooling over conventional homes insulated with fiberglass. Some foam at 3-1/2” thicknesses (R13.3) can outperform 10-1/2” of fiberglass at R-32. So much for “R” value. Hard to believe? Lets look at some everyday examples. How can 1/8 inch thick foam coffee cup protect us from 180 degree coffee? How can a Boeing 757 at 30,000 feet resist -30 degree F temperatures with only 1-1/2 inches of sprayed polyurethane foam between the passenger and the outside skin of the plane? Polyurethane foam works because it expands into areas of poorly fitted construction components to make a complete air seal around all members. Sealing out air from infiltrating your home eliminates noise, air, pollen, insects, rodents, rain and snow. The end result is a cleaner, quieter more comfortable living space with a savings payback period for polyurethane foam insulation being 2-1/2 to 3 years. Is there anything you can name that you can have installed in your home that will pay for itself in 2-3 years? Anything? Performance proven Polyurethane Spray foam insulation offers the homeowner much more than just R value. It just doesn’t make sense to insulate with anything but foam with energy costs due to increase again this fall heating season. If you are building new or have an existing structure that allows air to enter freely…don’t wait until the snow is falling before upgrading to polyurethane foam. Call your Polyurethane foam insulation contractor today for a free estimate. Chuck Skopelja Technical Sales Demilec (USA) LLC “A spray polyurethane systems manufacturer” chuck@sealection500.com