Mixer

advertisement

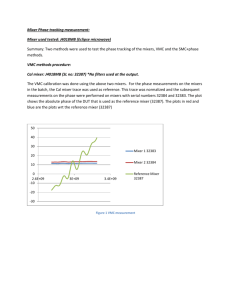

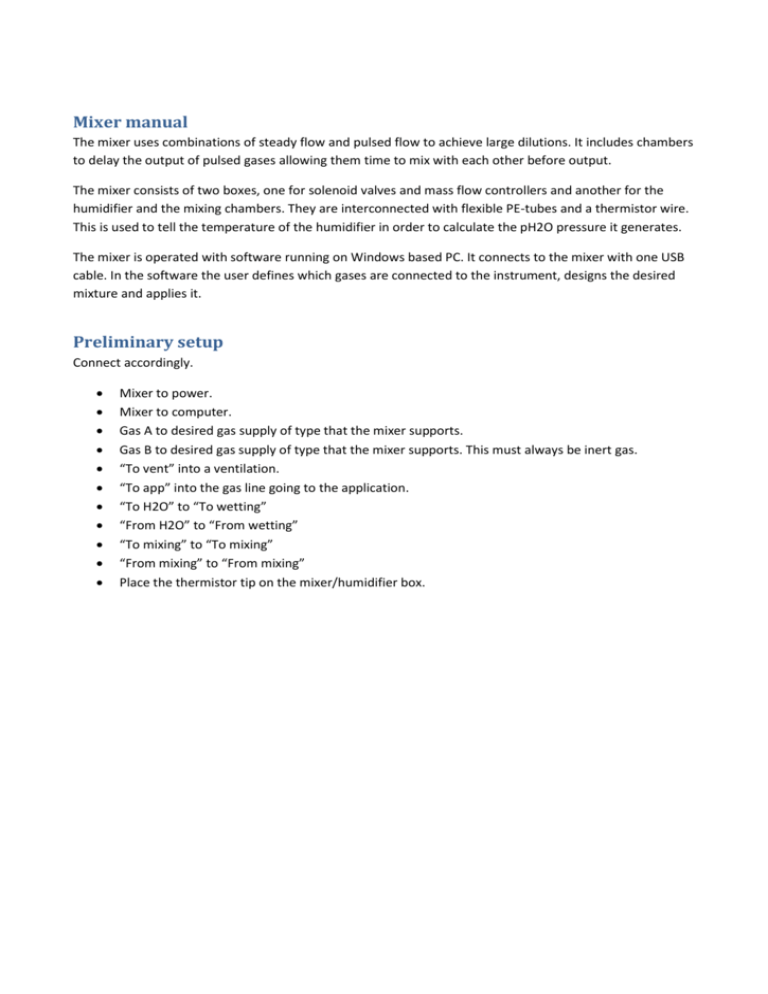

Mixer manual The mixer uses combinations of steady flow and pulsed flow to achieve large dilutions. It includes chambers to delay the output of pulsed gases allowing them time to mix with each other before output. The mixer consists of two boxes, one for solenoid valves and mass flow controllers and another for the humidifier and the mixing chambers. They are interconnected with flexible PE-tubes and a thermistor wire. This is used to tell the temperature of the humidifier in order to calculate the pH2O pressure it generates. The mixer is operated with software running on Windows based PC. It connects to the mixer with one USB cable. In the software the user defines which gases are connected to the instrument, designs the desired mixture and applies it. Preliminary setup Connect accordingly. Mixer to power. Mixer to computer. Gas A to desired gas supply of type that the mixer supports. Gas B to desired gas supply of type that the mixer supports. This must always be inert gas. “To vent” into a ventilation. “To app” into the gas line going to the application. “To H2O” to “To wetting” “From H2O” to “From wetting” “To mixing” to “To mixing” “From mixing” to “From mixing” Place the thermistor tip on the mixer/humidifier box. Setup tab In order to advance to the other tabs, the user must 1) list available ports, 2) select two separate ones of them and click validate. If the ports are correct ticks in checkboxes appear in box 5. Once user knows the right ports they typically will not change on a unique computer. When the checkboxes are ticked, select from available gases the ones connected to the mixer. In few seconds the third checkbox gets ticked. After this it is possible to proceed to other tabs. Operation tab “Stop button” will close all valves and set all flowmeters to 0-flow. “Flush button” will use the Gas B to flush each of the possible routes for some seconds. It may be necessary to flush a number of times. “Bypass button” will send pure Gas B to the application through the bypass. This functionality is to be used to quickly change from the diluted mixture to a dry and pure Gas B. If the mixing chambers are full of suitable mixture, one can change back to using that mixture by clicking the Dilution button. The “Dilution button” will start to formulate the mixture defined in the “Flow program” box. The user defines desired ppm levels of Gas A, Gas B and possibly H2O. The calculations are based on the mases of the gases which are measured by the mass flow controllers. Results can be show on the text area to the right. The mixer has a number of “Mixing methods” depending what type of mixture is being made. Mostly A is supposed to be diluted with B, and some mixing methods such a B diluted with A are not currently possible, but relatively easy to add if required. Output tab The output tab shows a log of mixer operation including total sent mass for each gas and the mass and molar fractions. It is possible to save this log by right-clicking the table. As a header the mixture info is also included in this *.csv file. Suggested name for the file includes current date and time and should be amended with sample- or user name. Humidifier Valid water level of the humidifier is between 4 and 4.5 on indicator. To refill the humidifier have squirt bottle with distilled or purified water. Remove the quick connections on the box from “To wetting” and “From wetting”. Place the tip of the bottle on the “To wetting” and squeeze the bottle gently. Make sure you apply gentle pressure so that you will never lose sight of the water level on the indicator. Too fast water pulse will push water higher than the water level indicator and potentially trap water and air in the gas lines, which would in turn cause wrong water level readings. When filling the humidifiers, the gas in the dead volume will be vented to the room. The thermistor tip is used to read the H2O temperature when a new mixture is calculated. Safety The mixer closes all valves and cuts off the gas flow when it is disconnected from power and this is the priority safety-act in case of a problem. The program itself will do the same when user clicks Stop button or closes the software, but this is dependable on the computer state and cable state. The mixer allows user to connect different gas species to it, but the previously used gas will be present in the humidifiers dead volume, dissolved into the H2O, in the gas lines and in the chambers. It needs to be flushed out before changing to new type of gas. Performance Specially the gas dissolved in the H2O will evaporate over long time and add small contribution of itself into the mixture. For mixtures with less than ~1000 ppm of gas A the dilution is performed by pulsing the gas A as a function of time. The gas then needs to properly mix with the dilutant before exiting the mixer.