Planetary mixers

advertisement

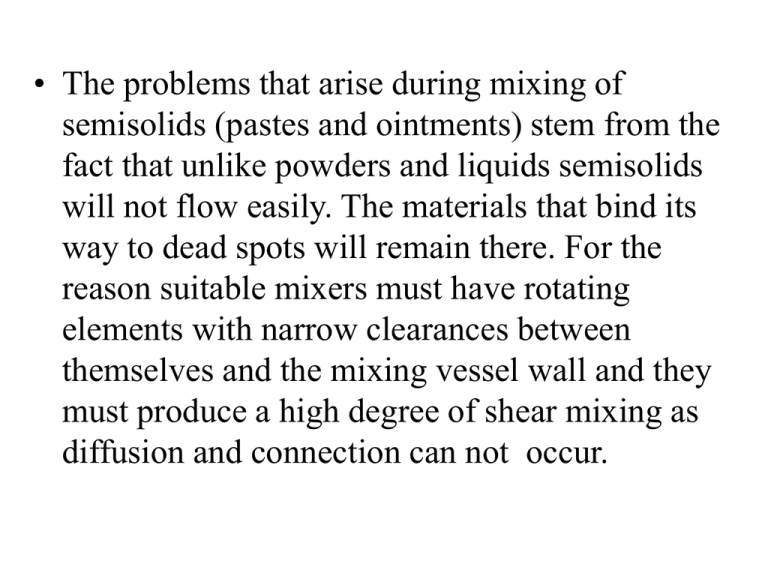

• The problems that arise during mixing of semisolids (pastes and ointments) stem from the fact that unlike powders and liquids semisolids will not flow easily. The materials that bind its way to dead spots will remain there. For the reason suitable mixers must have rotating elements with narrow clearances between themselves and the mixing vessel wall and they must produce a high degree of shear mixing as diffusion and connection can not occur. Mixers for paste mixing: • Planetary mixers: • The mixing blade is set off center and is carried on a rotating arm. It therefore travels round the circumference of the mixing bowl while simultaneously rotating around its own axis. This is therefore a double rotation similar to that of a spinning planet rotating around the sun, hence the name. Mixer blade Planetary gear Direction of drive Direction of rotation of planetary gear Stationary ring gear Top view • Planetary Mixers are used for dry mixing and dough mixing. The homogenous mixing if various lngredients of different densities in different proportions for solid/solid, liquid/solid, and liquld/Iiquid is achieved effectively by the use of Planetary Mixer. Vacuum Jacketed Planetary Mixers for the preparation of ointment; toothpaste; creams; suspensions. are designed to achieve the best results. All contact parts are made from S S 304 or SS 316 steel as per client's requirements. Standard Mixer is available in 200, 350 and 600 Liters... capacities. • Sigma – blade (double arm kneader mixer): • This robust mixer will deal with stiff pastes and ointments and depends for its action on the close intermeshing of the two blades which resemble the Greek letter ∑ in shape. The clearances between the blades and the mixing through are kept small. • Roller mills: • Roll mills can provide exceedingly high localized shear. Roller mills consisting of one or more rollers are in common use of these, three roll type seems to be preferred. A B C D E Fig: Cross section of three roll mill showing hooper (A), Roll (B,C,D) and Scraper (E)