Bonzeb Kiln Calculations – Part 02

advertisement

Bonzeb Kiln Calculations – Part 02

Overview

1.

2.

3.

4.

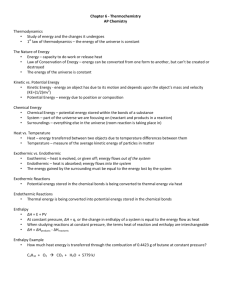

Background

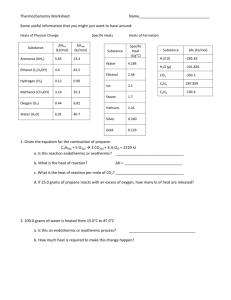

Determining Cp Value

How much propane would be required for that heat (adiabatic system)

How much syngas would be required for that heat (adiabatic system)

1. Background

These calculations are divided up into three parts. The first is to find how much heat will

need to go into the large kiln until the temperature raises from room temperature, 273 K,

to the ideal temperature for torrefaction (573 K). The second calculation will be

determining how much propane will need to be used to aquire the desire temperature.

The third calculation will be to determine how much syngas would be required for the

desired temperature. These calculations will be expressed as a rate, so when a mass of

elephant grass is put into a system, a transient analysis can be conducted.

For the following calculations, multiple assumptions will be assumed. Until a more

accurate Cp value can be determined for elephant grass, a Cp of 1.38 J/kg*K will be used

(this is the Cp value of soft wood [fir/pine]). In addition, the gas will be assumed to be

ideal so that instead of using enthalpy values, Cp values and temperatures can be used. In

addition, the system is considered to be adiabatic and reversible.

2. Determining Cp Values

𝑄𝑖𝑛 = ℎ2̇ − ℎ1 = 𝐶𝑝 (𝑇2 − 𝑇1 )

̇ = 1.38

𝑄𝑖𝑛

𝑘𝐽

𝑘𝐽

⁄𝑘𝑔 ∙ 𝐾 (573𝐾 − 273𝐾) = 414 ⁄𝑘𝑔

3. Determining how much propane would be required.

3.1 Determining the molar equation for combustion

𝐶3 𝐻8 + 5(𝑂2 + 3.76𝑁2 ) ⟶ 3𝐶𝑂2 + 2𝐻2 𝑂 + 5(3.76𝑁2 )

3.2 Determining the Balance of energy Equation

Rearranging the equation with respect to the combustion of methane with 100%

theoretical air, the equation becomes the following :

3(∆ℎ̅)𝑐𝑜2 + 2(∆ℎ̅)𝐻2 𝑜 + 18.8(∆ℎ̅)𝑁2 = [(ℎ°𝑓 )𝐶3 𝐻8 + 5(ℎ°𝑓 )𝑂2 + 18.8(ℎ°𝑓 )𝑁2 ] − [3(ℎ°𝑓 )𝐶𝑂2 +

2(ℎ°𝑓 )𝐻2 𝑂 + 18.8(ℎ°𝑓 )𝑁2 ] 3.3 The following code was put into EES to determine the rate of molar flow rate of

propane necessary to raise the temperature to 573K.

ch=c_('Hardwoods-oak-maple', 473)

cs=c_('Softwoods-fir-pine', 473)

Qin= cs*(T2-T1)

T1=273

T2=573

T3 = 1200

h_o_f_CO2 = -110530

h_o_f_H2O=-241820

h_o_f_C3H8=-103850

h_1_CO2=Enthalpy(CO2,T=T1)

h_3_CO2=Enthalpy(CO2,T=T3)

h_1_H2O=Enthalpy(Water,T=T1,P=101325)

h_3_H2O=Enthalpy(Water,T=T3,P=101325)

h_1_N2=Enthalpy(Nitrogen,T=T1,P=101325)

h_3_N2=Enthalpy(Nitrogen,T=T3,P=101325)

Qin= (3*(h_o_f_CO2+ (h_3_CO2-h_1_CO2))+2*(h_o_f_H2O+(h_3_H2Oh_1_H2O))+18.8*(h_3_N2-h_1_N2)-(h_o_f_C3H8))*n_dot

̇

𝒏𝑪𝟑 𝑯𝟖 = 𝟎. 𝟎𝟎𝟐𝟗𝟐

𝒎𝒐𝒍/𝒔

3.4 Converting to mass flow rate

𝑚𝐶3 𝐻8 = (

44.09𝑔

𝑔

) ∗ 𝑛𝐶3 𝐻8 = 0.129 = 0.00772 𝑘𝑔/𝑚𝑖𝑛

1𝑚𝑜𝑙

𝑠