Bari Textile Mills - Orient Water Technologies

advertisement

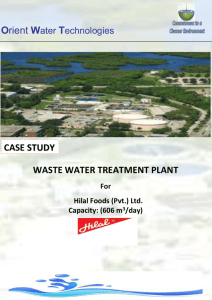

Orient Water Technologies CASE STUDY WASTE WATER TREATMENT PLANT Fo r BARI TEXTILE MILLS (Pvt.) Ltd. Capacity: (760 m3/day) 1 Introduction: Bari Textile Ltd, a third-generation family business, has steadily expanded its product line and production capabilities , more than 800,000 sq. feet of manufacturing facilities, including its in-house weaving, dyeing, bleaching, finishing, cut n sew, and distribution operations. Bari Textile Ltd , manufacture extensive selections of textiles, catering to a wide array of customers. Bari Textile Ltd , dominate the global hospitality market and cotton and polyester products are used at some of the leading hotels of the world. Plant use the same way of production) and also on the amount of used water. Also not all plants uses the same chemicals, especially companies with a special standard (environmental) try to keep water cleaned in all steps of production. So the concepts, to treat the water can differ from each other. 2 4 Technical Characteristics: The Plant’s average capacity is 760 m3/day. The treatment process is capable of producing product of following characteristics: Scope of Work: The contract included the complete of equipment, design, engineering, manufacturing, supply, installation, Civil work, Testing and plant commissioning. Having stronghold in the healthcare 3 General Information: industry. Having products are donned by The engineered waste water treatment old age patients as well as newborns. Major healthcare institutions plant consisted of the following: across the world are also on our client -Screening list. The textile industry is very water intensive. Water is used for cleaning the raw material and for many flushing steps during the whole production. Produced waste water has to be cleaned from, fat, oil, color and other chemicals, which are used during the several production steps. The cleaning process is depending on the kind of waste water (not every -Equalization -Neutralization -Aeration -Biological Sedimentation -Sludge Drying Beds -Screen Channel There are solids at high range inside the process water which comes with its own gravity. These solids firstly pass through a manual cleaning screen so the mechanical equipments at the system are protected and the load of the system is lightened. The solids which are kept, are removed together with the wastes. -Neutralization Before taking the wastewater to the chemical treatment, it is passed through a FINE SCREEN in order to keep the fibers inside and to make a more sensitive filtration. Wastewater which passes through the biological treatment. The efficiency of the screening operation depends of the spacing between screen bars: Fine screening, for a spacing under 10 mm Medium screening, for spacing of 10 to 40 mm Coarse screening, for spacing of over 40 mm. Untreated wastewater may require neutralization to eliminate either high or low pH values prior to certain treatment systems, such as biological treatment. Neutralization is a common practice in wastewater treatment and waste stabilization. If a waste stream is found to be hazardous because of corrosivity, neutralization is the primary treatment used. Moreover, neutralization is used as a pretreatment system before a variety of biological, chemical, and physical treatment processes. -Aeration -Equalization Process water which passes through the screen is taken to the equalization basin (in order to equalize the wastewater in terms of flow rate and pollution and to become homogenous) Wastewater is given to the system from the equalization basin to the system. The purpose of biological treatment is to remove soluble organics. In the activated sludge process, micro organisms (MO) are mixed with the organics so that they can grow and stabilize the organics. The system used for biological treatment is MIXED AERATION technology. The process is based on EXTENDED AERATION, where a considerable amount of sludge stabilization occurs already in the aeration tank. Oxygen for Biological treatment is provided by blower – diffuser system. Flow equalization is used to overcome the operational problems and flow rate variations to improve the performance of downstream processes and to reduce the size & cost of downstream treatment facilities. To prevent flow rate, temperature, and contaminant -Biological Sedimentation Tank concentrations from varying widely, flow After aeration, the wastewater is equalization is often used. taken into sedimentation unit. Here sludge is settled at the bottom of the tank, whereas top water overflows the weirs. Some portion of the settled sludge is recycled, while the other portion is wasted. The wasted sludge is collected in the sludge thickener unit. After biological treatment, wastewater is discharged. -Sludge Drying Beds The facility comprises sludge transfer , thickening recirculation , extraction and drying. Sludge thickeners are provided having 24 hours storage capacity. -Plant Control: The plant is fully controlled by programmable logic controller .In addition to the PLC , various instrumentations are located at different locations in plant to enable the operator and engineer to properly monitor and analyze the plant performance. The monitoring system is rated for hazardous area and is totally reliable unit installed in a dedicated control room. . Orient Water Technologies 5 Conclusion: As a result the waste water treatment plant by Orient Water Technologies managed to improve the performance of Bari Textile mills (Pvt.) Ltd. , whilst meeting the local environmental regulation Schematic Flow Diagram