Wastewater Treatment Process Online Tour

advertisement

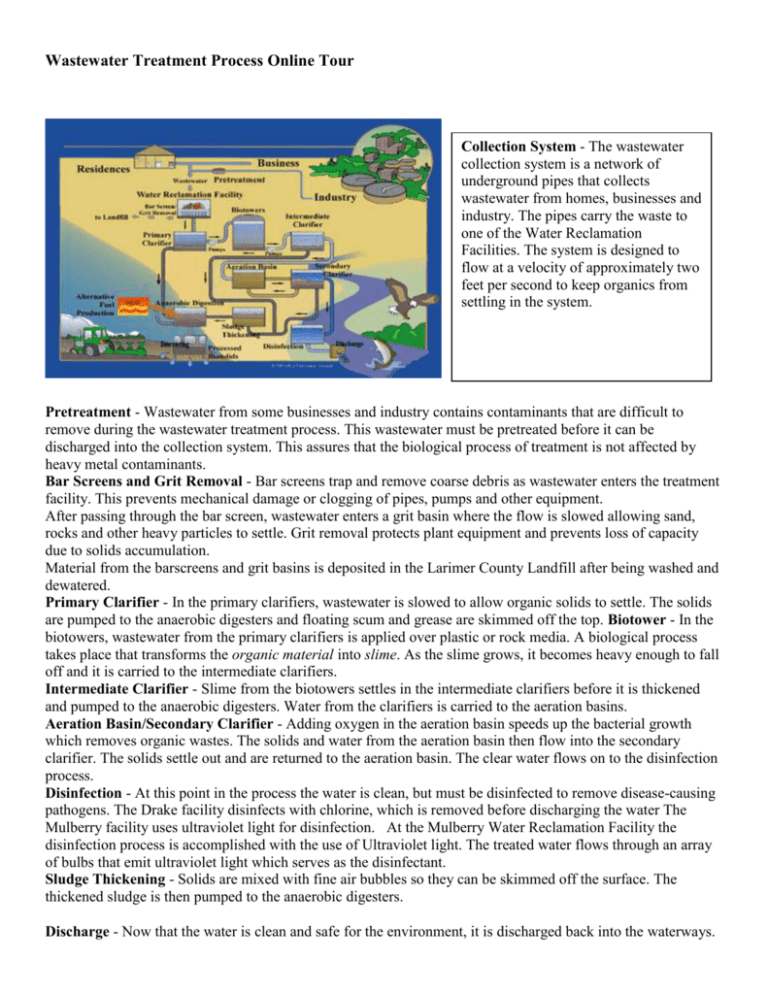

Wastewater Treatment Process Online Tour Collection System - The wastewater collection system is a network of underground pipes that collects wastewater from homes, businesses and industry. The pipes carry the waste to one of the Water Reclamation Facilities. The system is designed to flow at a velocity of approximately two feet per second to keep organics from settling in the system. Pretreatment - Wastewater from some businesses and industry contains contaminants that are difficult to remove during the wastewater treatment process. This wastewater must be pretreated before it can be discharged into the collection system. This assures that the biological process of treatment is not affected by heavy metal contaminants. Bar Screens and Grit Removal - Bar screens trap and remove coarse debris as wastewater enters the treatment facility. This prevents mechanical damage or clogging of pipes, pumps and other equipment. After passing through the bar screen, wastewater enters a grit basin where the flow is slowed allowing sand, rocks and other heavy particles to settle. Grit removal protects plant equipment and prevents loss of capacity due to solids accumulation. Material from the barscreens and grit basins is deposited in the Larimer County Landfill after being washed and dewatered. Primary Clarifier - In the primary clarifiers, wastewater is slowed to allow organic solids to settle. The solids are pumped to the anaerobic digesters and floating scum and grease are skimmed off the top. Biotower - In the biotowers, wastewater from the primary clarifiers is applied over plastic or rock media. A biological process takes place that transforms the organic material into slime. As the slime grows, it becomes heavy enough to fall off and it is carried to the intermediate clarifiers. Intermediate Clarifier - Slime from the biotowers settles in the intermediate clarifiers before it is thickened and pumped to the anaerobic digesters. Water from the clarifiers is carried to the aeration basins. Aeration Basin/Secondary Clarifier - Adding oxygen in the aeration basin speeds up the bacterial growth which removes organic wastes. The solids and water from the aeration basin then flow into the secondary clarifier. The solids settle out and are returned to the aeration basin. The clear water flows on to the disinfection process. Disinfection - At this point in the process the water is clean, but must be disinfected to remove disease-causing pathogens. The Drake facility disinfects with chlorine, which is removed before discharging the water The Mulberry facility uses ultraviolet light for disinfection. At the Mulberry Water Reclamation Facility the disinfection process is accomplished with the use of Ultraviolet light. The treated water flows through an array of bulbs that emit ultraviolet light which serves as the disinfectant. Sludge Thickening - Solids are mixed with fine air bubbles so they can be skimmed off the surface. The thickened sludge is then pumped to the anaerobic digesters. Discharge - Now that the water is clean and safe for the environment, it is discharged back into the waterways. Water from the Mulberry facility is discharged directly into the Cache la Poudre River. The Drake facility mainly discharges water into the Fossil Creek Ditch to be used by farmers for irrigation. Water also goes to Rawhide Power Plant as part of a reuse agreement. Anaerobic Digester - This process reduces the pathogens (biological poisons) and odors (eewww) of the incoming sludge. The anaerobic digester mixes and heats the sludge in an enclosed tank without oxygen. Anaerobic bacteria break down organics and produce methane gas. This gas is burned in boilers to supply heat for the process and for facility buildings. After 30 to 60 days, the sludge is ready for dewatering. Dewatering and Beneficial Use - Liquid biosolids (sludge) have the water taken out through chemical and physical processes. The resulting solid material is trucked to local farms and applied as a soil conditioner and fertilizer.