Hilal Foods - Orient Water Technologies

advertisement

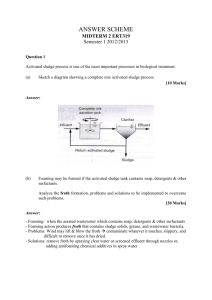

Orient Water Technologies CASE STUDY WASTE WATER TREATMENT PLANT For Hilal Foods (Pvt.) Ltd. Capacity: (606 m3/day) 1 4 Introduction: The food industry is a complex, global collective of diverse businesses that supply much of the food and food energy consumed by the world population. Only subsistence farmers , those who survive on what they grow, can be considered outside of the scope of the modern food industry. Technical Characteristics: The Plant’s average capacity is 606 m3/day. The treatment process is capable of producing product of following characteristics: 3 General Information: The engineered waste water treatment plant consisted of the following: � Screening � Equalization � Chemical treatment 2 Scope of Work: � Biological treatment � Sludge dewatering The contract included the complete of equipment, design, engineering, manufacturing, supply, installation, Civil work, Testing and plant commissioning. � Screening As the process water has solid particles, screening is the first unit used to filter wastewater in treatment plants to hold those particles. The main purpose of screens is to remove large objects from wastewater which may damage pumps and equipment. � Equalization � Biological treatment � Sludge dewatering Wastewater is taken into equalization tank for hydraulic and organic equalization and homogenization. Mixing is done via blower. There are pumps in the equalization tank. One of them is always standby as reserve while the other pumps are on duty. Those pumps feed the actual wastewater treatment plant in equal flow rate. The system which is used for the biological treatment is SEQUENCING BATCH REACTOR system. The most important property of the system is to be resistant of the bacterium to the shock loadings. Also, the easy control of the MLSS setting and the easy change of the operation parameters are the other important points. Sludge � Chemical treatment The necessary oxygen for Biological Chemical treatment consists of coagulation + flocculation + sedimentation units. First of all, wastewater is taken into coagulation tank. In this process coagulant is dosed into coagulation tank. Also lime is dosed into coagulation tank for pH adjusting. After that polyelectrolyte is dosed for flocculation. treatment is provided by the blower + The dewatering sludge conditioning. Then sludge is pumped into filter press pump. The sludge cake is taken away as solid waste and filtrate water from filter press is reverted into equalization tank. � Plant Control: plant is fully the complete mixture is provided at addition the After a to controlled by controller .In PLC, various multiple instrumentations are located at different biochemical reaction, the organic locations in plant to enable the operator materials inside the wastewater part and engineer to properly monitor and by microorganisms named the active analyze the plant performance. The sludge and then the wastewater is monitoring system is rated for hazardous taken into sedimentation phase. area and is totally reliable unit installed Following the sedimentation tank, the in a dedicated control room. After this unit, wastewater is wastewater which is collected by the taken into sedimentation tank. discharge pump, is filtrated. Then Chemically treated water overflows the weirs and is taken into biological treatment system. In the mean time the settled sludge is taken away from the sedimentation tank into the sludge unit. There are 2 by pass valves to take the wastewater to neutralization unit directly. to Polyelectrolyte dosing will be used for logic basin. necessary increase the solid content in the sludge. diffuser system and at the same time programmable the is wastewater is discharged. And the residual sludge is pumped into sludge tank. And the residual sludge is taken by truck or pumped into sludge dewatering unit. After wastewater is discharged that Orient Water Technologies 5 Conclusion: As a result the waste water treatment plant by Orient Water Technologies managed to improve the performance of Hilal Foods (Pvt.) Ltd. , whilst meeting the local environmental regulation Schematic Flow Diagram