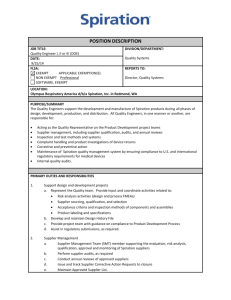

Laboratory Errors & CAPA: A Guide to Prevention

advertisement

www.GlobalHealthLaboratories.org This teaching material has been made freely available by the KEMRI-Wellcome Trust (Kilifi, Kenya). You can freely download, adapt, and distribute this presentation under the conditions that: the Global Health Laboratories and The Global Health Network are referenced; the work is not used for commercial purposes, and any altered forms of this document are distributed freely under the same conditions. LABORATORY ERRORS & CAPA KEMRI-Wellcome Trust Research Programme 2 Learning Objectives At the end of this presentation, you will be able to: Describe Laboratory errors and occurrences Identify causes of Laboratory errors Define the term “corrective action preventive action”. Differentiate preventive actions, remedial actions, and corrective actions. Describe the relationships between preventive action and risk management practices. Define and describe root cause analysis. 3 What is Laboratory Error? Laboratory error is an occurrence or an event that has a negative impact on Laboratory, which includes personnel, product, equipment, or the environment. 4 Some common laboratory errors patient ID error proficiency testing error lost sample sample delayed in transit no action on out of range controls false negative result contaminated samples late reports wrong test performed missing reports test performed Complaints inconsistent with the laboratory accident written procedure “near miss” 5 equipment not properly maintained QC, EQA not performed test kits not stored properly individual responsibilities unclear Common causes of error transcription errors checks not done no written procedures written procedures not followed training not done or not completed 6 Errors occurrence in Testing Process THE PATIENT Test selection Sample Collection Pre-examination Phase Sample Transport Laboratory Analysis Examination Phase Report Transport Result Interpretation Report Creation Post-examination Phase 7 Pre-examination Errors THE PATIENT Test selection Sample Collection Pre-examination Phase Sample Transport Examples include: wrong sample collected sample mislabeled or unlabeled sample stored inappropriately before testing sample transported inappropriately reagents or test kits damaged by improper storage 8 Examination Errors Examples: Laboratory Analysis Examination Phase established algorithm not followed incorrect timing of test results reported when control results out of range improper dilution and pipetting of sample or reagents reagents stored inappropriately or used after expiration date 9 Post-examination Errors Examples : transcription error in reporting report illegible report sent to the wrong location report not sent Report Creation Report Transport Result Interpretation Postexamination Phase 10 Risks of Laboratory Errors ERROR Inadequate or inappropriate patient care Inappropriate public health action Death Undetected communicable disease outbreaks Wasteful of resources 11 Detection of Laboratory Errors Customer satisfaction Accreditation Certification QMS COMMITTEE Monitoring complaints Management Review Quality indicators Internal audits External audits PT / EQA 12 Lab Errors Management Process Awareness Investigate Communicate ACTION 13 Corrective Action Preventive Action (CAPA) Learn from the event and avoid its recurrence Preventive actions See the potential event and plan to avoid it EVENT Remedial actions Corrective actions Address the event and its consequences 14 CAPA Process 1. Establish a CAPA Process. 2. Log findings and actions 3. Investigate causes, analyze information 4. Take appropriate action 6. Provide information to all needing it 5. Monitor for recurring problems 15 Laboratory Error Investigation steps information gathering thorough investigation root cause analysis 16 Root Cause Analysis Structured investigations that focus on identifying the underlying true causes of occurrences every cause has a deeper reason for each occurrence seek 5 levels of explanation, asking WHY, before being satisfied as to the true (root) cause 17 Root cause analysis example WHY? WHY? WHY? WHY? WHY? 18 Summary The laboratory should: employ an active process for occurrence management and take a positive approach. try to detect problems early, and take immediate remedial and corrective action. seek opportunities to identify potential error, thus preventing its occurrence. keep good records of all problems, investigations, and actions taken. 19 Key Messages The difference between a GCLP compliant laboratory and those nonGCLP compliance is that the compliant laboratory detects the problem, investigates, and takes actions. 20 COMMENTS SUGGESTIONS COMMENTS THANK YOU 21 What about your laboratory? List the 5 most common errors occurring in your laboratory. Why do they occur? What remedial actions did you take to address the immediate consequences? What measures could you put in place to correct the problem and prevent recurrence? How did you document the problem and action? Can you look at some of your common procedures to seek improvement and problem prevention? 22