docxDownload

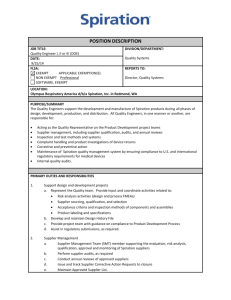

advertisement

ATK Aerospace Systems Brigham City, UT 84302-0707 Magna, Utah 84044-0098 QUALITY ASSURANCE DOCUMENT FQA-0176 QUALITY REQUIREMENTS FOR PURCHASE AGREEMENTS APPROVED : Mark Oja ____________________________________ M. Oja DIRECTOR, Quality Assurance Jean Vaniman ____________________________________ J. Vaniman MANAGER, Procurement Quality Assurance FORM FQA-0176 (Rev 3-10) TABLE OF CONTENTS INTRODUCTION........................................................................................................................................... 4 DEFINITIONS ............................................................................................................................................... 5 QUALITY REQUIREMENTS FOR PURCHASE AGREEMENTS ................................................................ 7 1.0 QUALITY SYSTEM REQUIREMENTS .............................................................................................. 7 1.1 MIL-Q-9858A QUALITY SYSTEM REQUIREMENTS .................................................................... 7 1.2 MIL-I-45208 INSPECTION SYSTEM REQUIREMENTS ............................................................... 7 1.3 QUALITY SYSTEM PER PURCHASE AGREEMENT ................................................................... 7 1.4 ISO9001 .......................................................................................................................................... 7 1.5 * CALIBRATION.............................................................................................................................. 7 1.6 AS9100 ........................................................................................................................................... 7 1.7 ** AS9120 ....................................................................................................................................... 7 1.8 ** AS9003 ....................................................................................................................................... 7 2.0 GENERAL QUALITY REQUIREMENTS ............................................................................................ 7 2.1 RIGHT OF ACCESS ....................................................................................................................... 7 2.2 TRACEABILITY .............................................................................................................................. 7 2.3 CHANGE NOTIFICATION .............................................................................................................. 8 2.4 DOCUMENTATION CONTROL ..................................................................................................... 8 2.5 ACCEPTANCE TOOLING .............................................................................................................. 8 2.6 ACCEPTANCE TEST PROCEDURES........................................................................................... 9 2.7 COMPLIANCE WITH FORM DD 250 ............................................................................................. 9 2.8 COMPANY LOT TRACEABILITY REQUIREMENTS ..................................................................... 9 2.9 ** INSPECTION/TEST VALUE ROUNDING .................................................................................. 9 3.0 PROCESS CONTROL ....................................................................................................................... 9 3.1 WORK INSTRUCTIONS ................................................................................................................. 9 3.1.1 WORK INSTRUCTION CHANGES.......................................................................................... 9 3.2 * STATISTICAL PROCESS CONTROL ....................................................................................... 10 3.3 SPECIAL PROCESSES ............................................................................................................... 10 3.3.1 * “INTENTIONALLY OMITTED” ............................................................................................. 10 3.3.1.1 MAGNETIC PARTICLE INSPECTION REPORT ............................................................. 10 3.3.2 WELDING............................................................................................................................... 10 3.3.2.1 WELDING CERTIFICATION ............................................................................................ 11 3.3.2.2 CLASS “A OR B” WELD DOCUMENTATION REQUIREMENTS ................................... 11 3.3.2.3 CLASS “C” WELD DOCUMENTATION REQUIREMENTS ............................................ 11 3.3.3 * “INTENTIONALLY OMITTED” .............................................................................................. 11 3.3.3.1 LIQUID PENETRANT INSPECTION REPORT ................................................................ 11 3.3.4 * “INTENTIONALLY OMITTED” ............................................................................................. 11 3.3.4.1 * RADIOGRAPHIC FILM/REPORT ................................................................................. 11 FORM FQA-0176 (Rev 3-10) 1 3.3.4.2 RADIOGRAPHIC FILM/REPORT FOR THIRD PARTY SHIPMENTS............................ 11 3.3.4.3 RADIOGRAPHIC FILM/REPORT FOR SECOND PARTY SHIPMENTS ....................... 12 3.3.5 * “INTENTIONALLY OMITTED” ............................................................................................. 12 3.3.5.1 ULTRASONIC INSPECTION REPORT .......................................................................... 12 3.3.6 * “INTENTIONALLY OMITTED” ............................................................................................. 12 3.3.6.1 ** EDDY CURRENT INSPECTION REPORT ................................................................. 12 3.3.7 AGE CONTROL ..................................................................................................................... 12 3.3.7.1 CURE DATE FOR O-RINGS AND RUBBER GOODS.................................................... 12 3.3.7.2 MANUFACTURING DATE .............................................................................................. 12 3.3.8 ENVIRONMENTAL CONTROL.............................................................................................. 12 3.3.8.1 SHELF LIFE AND STORAGE REQUIREMENTS (RSRM PROGRAM) ......................... 12 3.3.9 MODIFICATION OF QUALIFIED MATERIAL AND PROCESSES ........................................ 13 3.3.10 PERSONNEL TRAINING ..................................................................................................... 13 3.3.11 CONTAMINATION CONTROL ............................................................................................ 13 3.3.12 * “INTENTIONALLY OMITTED” ........................................................................................... 13 3.3.13 * TEFLON COATING ........................................................................................................... 13 3.3.14 ** COMPANY PROVIDED MATERIALS/COMPONENTS ................................................... 13 3.3.15 ** MANUFACTURING LOCATION(S) ................................................................................. 13 3.4 ** FOREIGN OBJECT DAMAGE (FOD) PREVENTION .............................................................. 13 3.4.1 ** FOREIGN OBJECT DAMAGE (FOD) INSPECTION ......................................................... 13 3.4.2 ** FOREIGN OBJECT DAMAGE (FOD) CERTIFICATION ................................................... 13 3.4.3 ** FOREIGN OBJECT DAMAGE (FOD) PREVENTION PROGRAM .................................... 13 4.0 INSPECTION AND REPORTING .................................................................................................... 14 4.1 MIL-STD-1520 CORRECTIVE ACTON SYSTEM FOR NONCONFORMING ITEMS ................. 14 4.1.1 * SUBMITTAL/RESUBMITTAL OF NONCONFORMING ITEMS .......................................... 14 4.1.2 * NONCONFORMING MATERIAL ......................................................................................... 14 4.2 * SAMPLING ................................................................................................................................. 16 4.3 VENDOR INSPECTION PLAN ..................................................................................................... 16 4.4 SUPPLIER INSPECTION FORMS ............................................................................................... 16 4.4.1 INSPECTION DATA ............................................................................................................... 16 4.4.2 LEGIBILITY OF PAPER WORK............................................................................................. 16 4.5 SOFTWARE CONTROL ............................................................................................................... 16 4.6 COMPANY FURNISHED MATERIALS ........................................................................................ 16 4.6.1 COMPANY SPECIFICATIONS USED FOR PROCUREMENT OF MATERIALS ................. 17 4.7 * FIRST ARTICLE INSPECTION OR PROCESS PROOFING .................................................... 17 4.7.1 ** FIRST ARTICLE INSPECTION PER AS9102 ................................................................... 17 4.8 * CERTIFICATE OF ANALYSIS ................................................................................................... 17 4.9 * CERTIFICATE OF CONFORMANCE ........................................................................................ 17 4.10 RETENTION OF RECORDS ...................................................................................................... 18 FORM FQA-0176 (Rev 3-10) 2 4.11 * COMPANY SOURCE INSPECTION ........................................................................................ 18 4.11.1 GOVERNMENT SOURCE INSPECTION ............................................................................ 18 4.11.2 GOVERNMENT SOURCE INSPECTION (NASA CONTRACTS) ....................................... 18 4.12 CRITICAL FASTENERS ............................................................................................................. 18 4.13 RAW CASTINGS AND FORGINGS ........................................................................................... 19 4.13.1 HEAT TREAT CERTIFICATION .......................................................................................... 19 4.13.2 TENSILE TESTING .............................................................................................................. 19 4.13.3 TEST REPORTS .................................................................................................................. 19 4.14 CHEMICAL, PHYSICAL AND/OR MECHANICAL TEST REPORTS ......................................... 19 4.15 * CRITICAL ITEM AND KEY CHARACTERISTIC CONTROL ................................................... 19 4.16 “INTENTIONALLY OMITTED” .................................................................................................... 19 4.17 * AUTHORIZATION TO SHIP (ATS) .......................................................................................... 20 4.18 * FORGING DATA PACKAGE .................................................................................................... 20 4.19 ** MATERIAL CERTIFICATION ................................................................................................. 20 4.20 ** MANUFACTURER CAGE CODE ........................................................................................... 20 5.0 AUDITS AND SURVEILLANCE ....................................................................................................... 20 5.1 * SUPPLIER PERFORMANCE OF AUDITS ................................................................................ 20 5.2 COMPANY AUDIT ........................................................................................................................ 21 5.3 SOURCE SURVEILLANCE .......................................................................................................... 21 FORM FQA-0176 (Rev 3-10) 3 INTRODUCTION This document defines the quality requirements for suppliers of materials (raw material, hardware, components, assemblies and tools) and services to ATK Aerospace Systems. THE SUPPLIER IS RESPONSIBLE FOR ASSURANCE, AND UPON REQUEST, TO PROVIDE OBJECTIVE EVIDENCE THAT ALL MATERIALS AND SERVICES PROVIDED ARE IN COMPLIANCE WITH THE PURCHASE AGREEMENT REQUIREMENTS WHETHER MATERIALS ARE MANUFACTURED OR SERVICES ARE RENDERED BY THE SUPPLIER DIRECTLY OR OBTAINED THROUGH PURCHASE AGREEMENTS WITH SUB-TIER SUPPLIERS. UNLESS OTHERWISE SPECIFIED THE SUPPLIER MAY SELECT ALL SUB-TIER SUPPLIERS. HOWEVER, WHETHER SELECTION WAS DICTATED BY ATK AEROSPACE SYSTEMS OR OF THE SUPPLIER’S CHOICE, THE SUPPLIER MUST FLOW DOWN THE APPLICABLE ATK AEROSPACE SYSTEMS PURCHASE AGREEMENT REQUIREMENTS TO THE SUB-TIER SUPPLIER. Only the paragraphs of this document that are referenced in the purchase agreement apply. Additional quality requirements may be stated directly in the purchase agreement and supplement the referenced paragraphs. In the event of conflict between the quality provisions and other purchase agreement requirements the supplier shall obtain clarification from ATK Aerospace Systems. All ATK Aerospace Systems approvals and supplier requests for approval referenced in this document shall be by and through the ATK Aerospace Systems buyer in writing. Unless otherwise specified, ATK Aerospace Systems, as referenced in this document for inquiry, notification or document submittal, is the ATK Aerospace Systems buyer. The word "Company" used throughout this document refers to ATK Aerospace Systems SUPPLIER EXCEPTIONS TO PURCHASE ORDER REQUIREMENTS ARE NOT ALLOWED. AN EXCEPTION IS ANY ATTEMPT TO CERTIFY MATERIAL TO A SPECIFICATION WITHOUT MEETING ALL REQUIREMENTS. EXAMPLES OF EXCEPTIONS ARE VALUES THAT DO NOT MEET SPECIFICATION REQUIREMENTS, ALTERNATE TEST METHODS, OR REVISIONS OTHER THAN THOSE SPECIFIED IN THE PURCHASE ORDER. *: Indicates that paragraph has been changed this revision. **: Indicates that paragraph is new this revision. FORM FQA-0176 (Rev 3-10) 4 DEFINITIONS **Company – The word "Company" used throughout this document refers to ATK Aerospace Systems. FBM – Fleet Ballistic Missile. NASA – National Aeronautics and Space Administration. RSRM – Reusable Solid Rocket Motor. PRR – Preliminary Review Record – A record that is initiated when a nonconformance is found or the acceptability of material is in question. DER/DR – Discrepancy Event Record / Discrepancy Report - A record that has been referred to the Material Review Board (MRB) for action. **Exception – A record that is initiated in the Pilgrim MRB system when a nonconformance is found or the acceptability of material is in question. **Issue – A record that is initiated in the Pilgrim MRB system to disposition and assign cause and corrective action for a nonconformance noted in an Exception. **ER (Event Record) – A record initiated in order to document a deficiency or unplanned event that clearly does not result in nonconformance to deliverable hardware or materials. **ATK nonconformance – refers to nonconformance documents including PRR, DER, DR, ER, Exception and Issue. Lot or Batch – A collection of material compounded at one time or during one continuous, uninterrupted process, bearing identification and treated as a unique entity. Nonconforming Material (NCM) – Deliverable material which has a departure from, or noncompliance to, a design document (specification, drawing, other approved product description, or planned quality inspection) or contractual requirement. Process Control Tooling – Tooling used in the fabrication of a component wherein there exists a requirement to maintain specific environmental conditions, such as time, temperature and pressure during part manufacture. ATS – Authorization To Ship – Company document used for submittal of required supplier data prior to shipment. VIP - Vendor Inspection Plan – Company document for identification of inspection requirements and recording of data (includes QCID, VIP, RIP etc…). QPSL - Qualified Product Supplier List – A Company document listing suppliers whose product has successfully met qualification requirements for a specific program. Document may be identified as (Qualified Product Suppliers List), (Products, Materials and Process List), (Approved Parts List) or (Materials and Process List). Quality Assurance Representative – A Company representative who visits a supplier to inspect products or otherwise verify supplier conformance to Company purchase agreements. Scrap – A Preliminary Review disposition for nonconforming material that is not useable for its intended purpose and which cannot be economically reworked or cannot be repaired in a manner acceptable to the Company. Repair – An MRB disposition where nonconforming material is returned to a useable condition although not within design requirements. Rework – A Preliminary Review or MRB disposition where nonconforming material is returned to complete design conformance when it can be accomplished without adverse effect and without using methods of manufacturing other than those originally used. Use-As-Is – An MRB disposition to use NCM without modifying the reported condition. The nonconforming condition is determined by Company engineering and quality representatives to be satisfactory for its intended use. Use-As-Is dispositions shall be referred to MRB, require MRB approval, and shall be completed on a DER. FORM FQA-0176 (Rev 3-10) 5 Special Tooling – All jigs, dies, fixtures, patterns, molds, gages, process equipment, special test equipment and other special equipment, and manufacturing aids acquired and/or fabricated by or for the Company for compliance with the purchase agreement. Sub-tier Supplier – A contractor that furnishes materials or services to a supplier who uses those materials or services to fulfill a Company purchase agreement requirement. Supplier – A contractor that furnishes materials or services in accordance with a Company purchase agreement. TULOG – (Tool Used in Lieu Of a Gage) Tooling used in the manufacture of product and also as a media of acceptance in lieu of Standard Measuring Instruments or gages to verify part dimensions. FORM FQA-0176 (Rev 3-10) 6 QUALITY REQUIREMENTS FOR PURCHASE AGREEMENTS 1.0 QUALITY SYSTEM REQUIREMENTS 1.1 MIL-Q-9858A QUALITY SYSTEM REQUIREMENTS The supplier shall provide and maintain a quality system that meets the requirements of MIL-Q-9858A. 1.2 MIL-I-45208 INSPECTION SYSTEM REQUIREMENTS The supplier shall provide and maintain an inspection system that meets the requirements of MIL-I-45208. 1.3 QUALITY SYSTEM PER PURCHASE AGREEMENT The supplier shall provide and maintain a quality system that will ensure that all products delivered conform to the drawings, specifications and requirements specified by the purchase agreement. 1.4 ISO9001 The supplier shall provide and maintain a quality system that meets the requirements of ISO9001 as currently amended. 1.5 * CALIBRATION The supplier shall provide and maintain a calibration system that meets at least one of the following requirements, as currently amended, in the performance of this contract. 1. MIL-STD-45662A “Calibration System Requirements” 2. ISO-10012-1 “Quality Assurance Requirements for Measuring Equipment” 3. ANSI/NCSL Z540.1 "American National Standard for Calibration” 4. ISO10012 “Measurement management systems Requirements for measurement processes and measuring equipment” 5. ANSI/NCSL Z540.3 “Requirements for the Calibration of Measuring and Test Equipment” 1.6 AS9100 The supplier shall provide and maintain a quality system that meets the requirements of AS9100. 1.7 ** AS9120 The supplier shall provide and maintain a quality systems that meets the requirements of AS9120. 1.8 ** AS9003 The supplier shall provide and maintain an inspection and test quality system that meets the requirements of AS9003. 2.0 GENERAL QUALITY REQUIREMENTS 2.1 RIGHT OF ACCESS All work and material may be subject to inspection and test by the Company and its customer at any place and time. The Company’s access to processes considered proprietary by the supplier will be by mutual agreement. If applicable, the supplier or sub-tier supplier shall provide the necessary facilities, equipment and assistance for the safety and convenience of the Company’s or its customer’s personnel in the performance of selected inspections and tests. 2.2 TRACEABILITY Parts to be delivered shall be identified by serial or lot numbers (as specified by the purchase agreement), part number, revision and, if applicable, change number and shall be traceable to the lots of raw materials used. When two or more parts are joined in an assembly, manufacturing and inspection records shall identify each part used in the assembly by serial or lot number, part number, revision and, if applicable, change number. FORM FQA-0176 (Rev 3-10) 7 Materials to be delivered shall be identified by lot or batch number, specification number, revision and, if applicable, change number, and be traceable to manufacturing and inspection records. The supplier may determine lot size unless otherwise specified in the purchase agreement. Serial or lot numbers shall not be duplicated within the manufacturing of the same part or material. The serial or lot numbers of scrapped or rejected parts or materials shall not be reused. Unless otherwise specified the supplier shall maintain traceability records on file available for review by the Company. Note: Additional Company lot traceability requirements may be imposed per section 2.8. 2.3 CHANGE NOTIFICATION The supplier shall provide advance notification to the Company of any change of the supplier's or sub-tier supplier's name, address, tooling, facilities, materials or processes. This includes but is not limited to fabrication, assembly, handling, inspection, acceptance or testing. 2.4 DOCUMENTATION CONTROL The supplier shall provide a system to ensure control of all documents (supplier and Company-furnished drawings, technical documents, manufacturing procedures, inspection and test procedures) and for the incorporation of changes thereto. Documents shall be distributed to the proper places; e.g., manufacturing and inspection stations, receiving inspection, etc., at the prescribed times to ensure that changes are accomplished at the proper effectivity point, changed materials are appropriately marked and all obsolete documents are removed from use. 2.5 ACCEPTANCE TOOLING Selection of tools and standard measuring instruments is the option of the supplier except as follows: 1. The supplier shall control standard measuring instruments and tools used for acceptance. 2. Tools and standard measuring instruments used for acceptance shall be calibrated in accordance with MIL-STD-45662A, ISO 10012 or ANSI/NCSL Z540-1. 3. Prior to use, manufacturing tools to be used as TULOGs and specially designed acceptance gages require Company approval and, at the Company's option, proofing. 4. Tools that receive Company approval to be used as TULOGs shall comply with a supplierestablished periodic inspection program acceptable to the Company. Use of a tools shall be discontinued pending Company approved reproofing if the tool is: 1. 2. 3. 4. 5. Moved to a facility other than where proofed Damaged Removed from the Company inspection form Found to produce a defective product Classified defective as a result of periodic tool inspection. 5. Departure from Company specified inspection methods requires prior written Company approval. 6. Tooling furnished by the Company or its customer shall not be modified without prior written authorization by the Company. 7. Acceptance gage tolerance shall be no greater than ten percent of the total tolerance of the attribute being inspected unless otherwise approved by the Company. FORM FQA-0176 (Rev 3-10) 8 2.6 ACCEPTANCE TEST PROCEDURES The supplier shall prepare test procedures detailing all tests required for acceptance. Each item or part thereof that requires acceptance testing shall be covered by an acceptance test procedure. Test procedures require Company approval prior to delivery of first article. All subsequent changes to any acceptance test procedure are subject to Company approval. Where these tests are performed using equipment controlled by computer software or firmware, the software or firmware associated with, or affecting those tests, shall be approved by the Company. 2.7 COMPLIANCE WITH FORM DD 250 The supplier shall complete and submit Form DD 250, Material Receiving and Inspection Report. Preparation of the form shall be in accordance with DFARS 52.246-7000 Appendix F. Contact the cognizant Company buyer for copies of the form. 2.8 COMPANY LOT TRACEABILITY REQUIREMENTS When the Company requires per the contract the material to be a Company supplied lot number, one supplier lot number is used for one Company supplied lot number. The supplier may apply one supplier lot number to several different Company supplied lot numbers, but no more than one supplier lot number may be used on one Company supplied lot number. Company supplied lot number shall not be duplicated within the manufacturing of the same part or material. The Company supplied lot numbers of scrapped or rejected parts or materials shall not be used. The supplier must provide advance change notification for any change beyond the supplier/ Company agreement of the established manufacturing process of a lot. Unless otherwise specified in the purchase agreement, the supplier may determine the supplier lot size relative to unit of measure (e.g., each, kit, pounds) per the contract. 2.9 ** INSPECTION/TEST VALUE ROUNDING All limits in Company specifications and drawings are absolute unless stated otherwise in the specification or drawing. The supplier shall not round attribute values into conformance with engineering limits. 3.0 PROCESS CONTROL 3.1 WORK INSTRUCTIONS The supplier shall have written work instructions that provide for consistent manufacturing operations. All materials, process steps and process control tooling shall be identified in the work instructions. Special tooling shall be noted by its identifying number in the operational sequence in which it is used. Recording of all materials and processes used for manufacture shall be provided in the work instructions. Fabrication or processing of materials shall not begin prior to implementation and proofing of work instructions or changes thereto. 3.1.1 WORK INSTRUCTION CHANGES Work instructions, or changes thereto, which affect the requirements of Company controlled drawings or specifications require Company approval prior to implementation. Proposed changes to work instructions submitted to the Company shall contain the following information: 1. A complete description of the change, including a statement of the "From" and "To" conditions of the change. 2. Justification for the change, including background information in sufficient detail to allow an adequate study of the proposed change. FORM FQA-0176 (Rev 3-10) 9 3. The proposed effectivity of the change, stated either in terms of a calendar date or a part serial / lot number. 4. A copy of the revised work instruction. 3.2 * STATISTICAL PROCESS CONTROL The supplier shall use statistical process control (SPC) for controlling the manufacturing process. The Company shall approve the SPC plan prior to manufacture of product. The use of SPC does not supersede the requirements of 3.3.9, Modification of Qualified Material and Processes. 3.3 SPECIAL PROCESSES Special processes are segregated into fabrication special processes (e.g., soldering, coating, welding, heat treating and plating) and Nondestructive Inspection (NDI) special processes (e.g., ultrasonic inspection, radiographic inspection, eddy current inspection, magnetic particle inspection and penetrant inspection, including pre-penetrant etch). Personnel performing special processes shall be certified in accordance with applicable special process specifications. Personnel performing NDI special processes shall be certified to NAS-410 or as specified in the purchase agreement. The supplier shall have records of its personnel certifications and sub-tier supplier special process approvals on file, available for review by the Company. The supplier and any sub-tier supplier shall either have special processes approval by the Company, or the supplier's system to control its sub-tier supplier's special processes shall have been approved by the Company. Approval of special process sub-tier suppliers does not relieve the supplier of the responsibility for exercising those control measures necessary to ensure that work performed by sub-tier suppliers is in accordance with specification requirements. For each part requiring NDI special processes, the supplier or sub-tier supplier shall complete a technique chart and submit it to the Company for approval. The chart may be in the supplier's or sub-tier supplier's format and shall be the document used for the actual inspection. An applicable requirement checklist and example of a technique chart are attached to this document. Note 1: The Company shall approve the technique chart and any change thereto prior to NDI for product acceptance unless otherwise specified in the purchase agreement. Note 2: Technique charts approved for the same part on previous procurements need not be resubmitted if the inspection technique is unchanged. Note 3: The technique chart number and revision should be recorded on the test reports submitted by the supplier to the Company. 3.3.1 * “INTENTIONALLY OMITTED” 3.3.1.1 MAGNETIC PARTICLE INSPECTION REPORT The supplier shall include a magnetic particle inspection report listing the specification number and revision used, statement for acceptance criteria used, and a statement that magnetic particle inspection has been performed on items being supplied in accordance with applicable specifications. Authorized acceptance stamp or signature shall be affixed. A typed name submitted by the Supplier is a legally acceptable substitute. 3.3.2 WELDING The supplier shall maintain certified status of all welding personnel and welding facilities used in performance of this contract in accordance with AWS D17.1 for fusion welding and weld inspection and SAE-AMS-W-6858 for spot and seam welding. FORM FQA-0176 (Rev 3-10) 10 3.3.2.1 WELDING CERTIFICATION The supplier shall include a welding certificate listing the specification number and revision used, with a statement that welding has been performed on items being supplied in accordance with applicable specifications. An authorized acceptance stamp or signature shall be affixed. A typed name submitted by the supplier is a legally acceptable substitute. 3.3.2.2 CLASS “A OR B” WELD DOCUMENTATION REQUIREMENTS Prior To Fabrication: The supplier will provide to the Company for review and approval, before the start of any production welding, the applicable weld procedure(s), each welder’s or weld operator’s qualification record/report and the process that will be used, in accordance with AWS D17.1 section 4.4. With Shipment: 1. Provide name of welder(s), welder(s) signature, and process(es) used on Certification of Conformance as compliance to AWS D17.1 paragraph 8.5.10. 2. Provide a copy of the supplier Welding Approval sheet that has been approved by the Company. 3. Provide an inspection report by an AWS CWI or qualified visual weld inspector approved by the Company. Include a copy of AWS certification if an AWS CWI is used, as Certification of Compliance to AWS D17.1 paragraph 6.1.2 and 6.2. 3.3.2.3 CLASS “C” WELD DOCUMENTATION REQUIREMENTS Prior To Shipment: The supplier shall ensure each welder or weld operator is qualified in accordance with AWS 17.1 paragraph 8.4.1 and 8.4.2 prior to performing any welding. With Shipment: 1. Provide name of welder(s), welder(s) signature and process(es) on Certification of Conformance as compliance to AWS D17.1 paragraph 8.5.10. 2. Provide inspection report by an AWS CWI or qualified visual weld inspector approved by the Company. Include a copy of AWS certificate if an AWS CWI is used as Certification of Conformance to AWS D17.1 paragraph 6.1.2 and 6.2. 3.3.3 * “INTENTIONALLY OMITTED” 3.3.3.1 LIQUID PENETRANT INSPECTION REPORT The supplier shall include a liquid penetrant inspection report listing the specification number and revision used, statement for acceptance criteria used, and a statement that liquid penetrant inspection has been performed on items being supplied in accordance with applicable specifications. An authorized acceptance stamp or signature shall be affixed. A typed name submitted by the supplier is a legally acceptable substitute. 3.3.4 * “INTENTIONALLY OMITTED” 3.3.4.1 * RADIOGRAPHIC FILM/REPORT The supplier shall furnish x-ray/n-ray film and x-ray/n-ray reports with each shipment, stating the specification number and revision used statement for acceptance criteria used, and a statement that xray/n-ray inspection has been performed on items being supplied in accordance with applicable specifications. An authorized acceptance stamp or signature shall be affixed. A typed name submitted by the supplier is a legally acceptable substitute. 3.3.4.2 RADIOGRAPHIC FILM/REPORT FOR THIRD PARTY SHIPMENTS In case of shipment of part(s) to a third party, x-ray/n-ray film and x-ray/n-ray reports shall be sent to the Company at the time of shipments. FORM FQA-0176 (Rev 3-10) 11 3.3.4.3 RADIOGRAPHIC FILM/REPORT FOR SECOND PARTY SHIPMENTS When part(s) are sent to another vendor for machining, re-identification, and subsequent delivery to the Company, all applicable x-ray/n-ray film and x-ray/n-ray reports shall accompany the part(s). 3.3.5 * “INTENTIONALLY OMITTED” 3.3.5.1 ULTRASONIC INSPECTION REPORT The supplier shall include an ultrasonic inspection report listing the specification number and revision used with a statement that ultrasonic inspection by the contact or immersion method has been performed on items being supplied in accordance with applicable specifications. An authorized acceptance stamp or signature shall be affixed. A typed name submitted by the supplier is a legally acceptable substitute. 3.3.6 * “INTENTIONALLY OMITTED” 3.3.6.1 ** EDDY CURRENT INSPECTION REPORT The supplier shall include a eddy current inspection report listing the specification number and revision used, statement for acceptance criteria used, and a statement that eddy current inspection has been performed on items being supplied in accordance with applicable specifications. An authorized acceptance stamp or signature shall be affixed. A typed name submitted by the supplier is a legally acceptable substitute. 3.3.7 AGE CONTROL Material that degrades with age shall be marked to indicate the date when the useful life expires as defined by the applicable specification, drawing or purchase agreement. Further, the compounding dates, curing completion dates, manufacturing processing completion dates, and assembly dates (date of assembly completion by the supplier), as required by the applicable specification, drawing or purchase agreement, shall be included in the inspection data package. 3.3.7.1 CURE DATE FOR O-RINGS AND RUBBER GOODS Rubber goods delivered under this contract shall conform to the requirements set forth in MIL-STD-1523. If applicable, non-installed ‘O’ rings shall be individually packaged in a preservative wrapping in accordance with MIL-P-116 that is marked with “Cure Date”, and shall be delivered to the Company within six (6) months of the cure date. 3.3.7.2 MANUFACTURING DATE The supplier shall include the manufacturing date of material in acceptance documentation. 3.3.8 ENVIRONMENTAL CONTROL The supplier shall establish and maintain a documented system for control of material sensitive to environmental degradation. Material that may degrade in shipment or during storage shall be shipped or stored as specified by the applicable drawing, specification or purchase agreement. 3.3.8.1 SHELF LIFE AND STORAGE REQUIREMENTS (RSRM PROGRAM) When specified on Company drawings and/or specifications, shelf life and storage requirements shall apply as stated. In the event they do not coincide with supplier shelf life and storage requirements, the Company requirements take precedence, and the supplier will notify the Company of the disparity. When shelf life and storage requirements are applicable, the supplier shall include the recommended requirements, The requirements shall designate the following (as applicable): 1. When the shelf life begins (i.e., date of manufacture, ship date, or date of receipt). 2. Any environmentally sensitive information (i.e. either state “not environmentally sensitive” or state recommended storage temperatures and allowable excursion time and temperature allowances). FORM FQA-0176 (Rev 3-10) 12 3.3.9 MODIFICATION OF QUALIFIED MATERIAL AND PROCESSES The supplier shall notify the Company of any proposed changes to Company, supplier, and sub-tier supplier approved designs (including proprietary designs), fabrication and test methods, processes, tooling or nonconforming material, and shall obtain Company approval prior to change incorporation. If this order is for product that has been previously qualified and listed on a QPSL it must be manufactured and accepted under the same conditions using the same processes and methods by the same manufacturer and acceptance agency as material previously supplied. 3.3.10 PERSONNEL TRAINING The supplier shall ensure that personnel whose work has an effect on the quality of the product are trained. Training shall include pertinent subjects relating to manufacturing, inspection, testing, packaging and handling techniques and shall be documented. 3.3.11 CONTAMINATION CONTROL The supplier shall clean articles ordered under this contract per Company contamination control specifications. Cleaning and/or testing of the articles shall be performed in facilities with Company approved procedures and equipment. Each article shall be identified with a tag certifying its cleaning status and identification. The tag shall not be in contact with significant surfaces. 3.3.12 * “INTENTIONALLY OMITTED” 3.3.13 * TEFLON COATING Teflon coating to be performed per Company specification SP-V-GF-3.1.1. Teflon application to be performed by a Company approved Teflon supplier. Supplier shall provide processing documentation as required per paragraph 5.4h of specification SP-V-GF-3.1.1. 3.3.14 ** COMPANY PROVIDED MATERIALS/COMPONENTS When Company provided materials or components are used by the supplier, Company specifications and accept tags take precedence over any other marking or manufacturer recommendations. The supplier shall use materials in accordance with Company shelf life, usage life, and storage condition requirements. 3.3.15 ** MANUFACTURING LOCATION(S) The supplier shall include the manufacturing location(s) of material in acceptance documentation. 3.4 ** FOREIGN OBJECT DAMAGE (FOD) PREVENTION Deliverable items under this contract shall be free of FOD that can be detected by a visual inspection. 3.4.1 ** FOREIGN OBJECT DAMAGE (FOD) INSPECTION Prior to closing inaccessible or obscured areas or compartments during assembly the supplier shall inspect for foreign objects/materials. Tooling, jigs, fixtures, test equipment, and handling devices shall be maintained in a state of cleanliness and repair to prevent foreign object damage. 3.4.2 ** FOREIGN OBJECT DAMAGE (FOD) CERTIFICATION Supplier shall provide a statement of certification that deliverable products are free of any foreign materials that could cause damage to the product or to the components/systems of which the product is a part or to which the product is attached. 3.4.3 ** FOREIGN OBJECT DAMAGE (FOD) PREVENTION PROGRAM The supplier shall maintain a FOD control program assuring work is accomplished in a manner preventing foreign objects or material from entering and remaining in deliverable items. Maintenance of the work area and control of tools, parts, and material shall preclude the risk of FOD incidents. The supplier shall FORM FQA-0176 (Rev 3-10) 13 document and investigate all FOD incidents assuring elimination of the root cause. The Company shall have the right to perform inspections and/or audits as a method of verification that the supplier’s FOD control program is functional, documented, and effective. The supplier shall identify a FOD control person responsible for implementing FOD prevention awareness and training. 4.0 INSPECTION AND REPORTING 4.1 MIL-STD-1520 CORRECTIVE ACTON SYSTEM FOR NONCONFORMING ITEMS The supplier shall provide and maintain a corrective action system that meets the requirements of MILSTD-1520 and is acceptable to the Company. Delegation of Material Review Board (MRB) activities is not authorized by this clause. 4.1.1 * SUBMITTAL/RESUBMITTAL OF NONCONFORMING ITEMS Material/items which have undergone ATK nonconformance dispositioning shall be accompanied by the supplier's shipping document, Certification of Conformance and, as applicable, Vendor Inspection Plan each of which shall reference the ATK nonconformance document number(s). The Certificate of Conformance shall indicate the condition for submittal or resubmittal (i.e., "reworked per ATK nonconformance document [number]"; "replacement for lot/serial [number] and ATK nonconformance document [number]"; "Repair per Discrepancy Report or Pilgrim Issue [number]"). A copy of the dispositioned ATK nonconformance document shall also accompany the shipment. Supplier records shall be maintained and available to provide traceability of items/materials throughout rework/repair, replacement, inspection and submittal or resubmittal shipment. In the event the Company and supplier agree that nonconforming material or items will not be submitted or resubmitted (i.e., reduction in Contract quantity), the supplier shall document the final physical disposition (i.e., Scrap, etc.) by letter to the Company 4.1.2 * NONCONFORMING MATERIAL The supplier shall notify the Company of any nonconformances that require Company material review. A report number shall be assigned to each letter or message and shall include the following information: 1. Date and purchase agreement number. 2. Supplier's name and, if different, manufacturer's name. 3. Nomenclature of material. 4. Drawing or specification number, revision and, if applicable, change number. 5. Material serial or lot number (subcomponent serial or lot number, if applicable). 6. Exact description of nonconformance, VIP item number (if applicable), reference to the drawing location and requirement (Example: Sheet 6, Zone 4-B, Detail F, should be 5.000 + 0.010, is 5.015). Note: NDI nonconformances require submission of the NDI report with the discrepancy fully located and identified. 7. Supplier's recommended disposition. 8. A positive statement defining the cause and corrective action, including effectivity of corrective action. Note: The cause statement shall specifically address the nonconformance. The corrective action statement shall designate effectivity by serial number, lot number or date. The Company requires FORM FQA-0176 (Rev 3-10) 14 objective evidence of corrective action implementation. If corrective action is complete, submit the objective evidence with the material review request; if not, submit upon completion. 9. Company Quality Assurance Representative concurrence if in residence. In the event the Company permits use of the nonconforming material, the supplier shall record the applicable ATK nonconformance document number furnished by the Company on the inspection data forms for the material. A copy of the ATK nonconformance document shall be included in the inspection data package. When the supplier receives a copy of the ATK nonconformance document with a disposition of "Rework" or "Repair", the supplier shall perform the Rework or Repair specified and either stamp the ATK nonconformance document "Verification of Rework/Repair" block titled "Mfg Stamp" with an acceptance stamp or submit objective evidence (documentation) to verify work accomplishment. If Rework or Repair is not acceptable, the supplier shall repeat the material review process. A Company Quality Assurance Representative, if in residence, shall accept the Rework or Repair by signing or stamping the ATK nonconformance document "Verification of Rework/Repair " block titled "QC Stamp". The supplier shall retain a copy of the completed ATK nonconformance document bearing the acceptance stamp, include a copy in the inspection data package and immediately forward another copy to the Company. Material rejected/scrapped by the Company requires Company approval of any subsequent effort to make the material useable. Any material rejected by the Company and subsequently resubmitted by the supplier shall bear indication of such resubmission on the material and the associated supplier documentation. The associated supplier documentation (discrepancy report, corrective action report, reinspection data, etc.) shall be identified with the same lot or serial number as the material. The supplier shall contact the Company for identification of material submitted as replacements for Company or supplier rejected material. Note: Material that has been returned to the supplier for Company authorized "Rework" or "Repair" shall not be reidentified. FOR FBM PROGRAMS The supplier may disposition nonconforming material as follows after the supplier's Quality and Engineering personnel determine which of the following applies: 1. Reject - material is not usable and cannot be economically reworked or repaired. 2. Complete - material is incomplete to requirements and can be readily corrected without adverse effect using the same methods or instructions as originally used. 3. Rework - material nonconformance may be eliminated using Company-approved written procedures or other methods of correction that are allowed by the Company design. 4. Refer to the Company - The Company shall make all other material dispositions unless otherwise directed by the purchase agreement. Materials that require Company material review for disposition shall not be used, shipped or subjected to further processing that will alter or cover the nonconforming condition unless approved by the Company. FOR NON-FBM PROGRAMS Nonconforming material may be dispositioned “Scrap” or “Rework” by the supplier's Quality and Engineering personnel. The Company shall make all other material dispositions unless otherwise directed by the purchase agreement. Materials that require Company material review for disposition shall not be used, shipped or subjected to further processing that will alter or cover the nonconforming condition unless approved by the Company. FORM FQA-0176 (Rev 3-10) 15 4.2 * SAMPLING Sampling plans shall not be used to accept design parameters of serialized hardware unless specifically authorized by the Company inspection documents, a Company-approved supplier inspection plan, or the purchase agreement. Unless otherwise specified in the material specification, a Company approved supplier inspection plan or the purchase agreement, sampling of lotted material shall be in accordance with Standard Sampling Plans (MIL-STD-105, MIL-STD-414, MIL-STD-1916, ANSI/ASQ Z1.4,or ANSI/ASQ Z1.9) only, with prior Company approval of the inspection level. Should the supplier wish to implement a different sampling plan, Company approval shall be obtained prior to use. 4.3 VENDOR INSPECTION PLAN A completed Vendor Inspection Plan (VIP) shall accompany each shipment of material. The Company shall supply the form to the supplier. The copy returned to the Company must be legible and reproducible. Each item of the VIP shall be dated and verified by the supplier and/or the Company Quality Assurance representative as applicable, including Government Source Inspection (GSI) buyoffs. 4.4 SUPPLIER INSPECTION FORMS The supplier shall perform inspection of all material manufactured for this order. The supplier's inspection of each requirement shall include all dimensions and tests on applicable specifications and drawings unless otherwise stated in the purchase agreement. The requirement and inspection data to show acceptance shall be recorded on the supplier's own format. The supplier’s inspection plan shall be submitted for Company approval. A copy of the inspection data shall accompany each shipment, marked to the attention of Receiving Quality Control. Sampling inspection is not authorized under this provision unless specifically stated in the purchase agreement. 4.4.1 INSPECTION DATA With each shipment, the supplier shall include an inspection data package with the required inspection data and all approved PRRs/DER's/DR’s. The supplier shall furnish inspection data for each serialized part or each lot and for tests accomplished in accordance with this contract along with a statement of conformance and an authorized acceptance stamp or signature, unless otherwise specified. A typed name submitted by the supplier is a legally acceptable substitute. 4.4.2 LEGIBILITY OF PAPER WORK All inspection records, certifications and supporting documentation shall be done using permanent, reproducible ink. Supplier is to ensure legibility and reproducibility of all entries, stamps, imprints, and signatures. Errors may be voided by drawing a single line through the entry, recording the correct entry above or adjacent to the voided entry, initialing and dating. Do not erase/write over or blank out. The use of liquid paper (white-out) or correction tape is prohibited. 4.5 SOFTWARE CONTROL When computer software is used as medium of acceptance, either singly or in conjunction with tooling, the supplier shall develop and implement a plan for control of software (or firmware). Configuration and change control, method for design review, verification and proofing, storage of master control software and firmware shall be included in the plan. The Company shall approve the plan before the software is used to accept product. This paragraph does not apply to software used in the operation of commercial off-the-shelf inspection devices. 4.6 COMPANY FURNISHED MATERIALS It is the supplier's responsibility to inspect Company furnished material upon receipt for identification, count, condition and assurance of the presence of required documentation. Nonconforming material or material not fitting the supplier's tooling shall be identified, segregated and withheld from further processing. The Company shall be notified of nonconforming material. FORM FQA-0176 (Rev 3-10) 16 4.6.1 COMPANY SPECIFICATIONS USED FOR PROCUREMENT OF MATERIALS Materials used to manufacture items per this contract shall be certified to Company specifications and revisions. Suppliers purchasing these materials shall flow this Company requirement to sub-tier suppliers. 4.7 * FIRST ARTICLE INSPECTION OR PROCESS PROOFING The Company will perform a First Article Inspection or Process Proofing of material produced at the supplier or subtier’s facility. The First Article may be for proofing a tool or software prior to approving the tool for product acceptance, or to verify material compliance to the design. The Company will coordinate with the supplier and establish the requirements for the inspection or proofing. The supplier shall contact the Company prior to the start of fabrication so that mandatory in-process inspection/test points can be agreed upon. 4.7.1 ** FIRST ARTICLE INSPECTION PER AS9102 The supplier shall perform a First Article Inspection, in accordance with AS9102, of material produced at the supplier or subtier’s facility. 4.8 * CERTIFICATE OF ANALYSIS The supplier shall include in the inspection data package a legible and reproducible copy of a Certificate of Analysis (C of A). Along with other required documentation, the C of A shall accompany the product upon delivery to the Company. In addition to all the items specified in Paragraph 4.9 (Certificate of Conformance), the C of A shall contain the following data/information: (Note – A valid C of A indicates that the product/material being offered meets all the requirements in the controlling specification/drawing including applicable test methods, marking, packaging, packing, workmanship, sampling, and any other requirements). 1. Chemical, physical and/or mechanical test data that show compliance to all applicable requirements of the applicable drawing or specification. Test data shall be actual values obtained from testing of the material (lot) submitted. Where specific test methods are required by the specification/drawing, the test methods used shall agree exactly with the methods stated in the specification/drawing. Different or equivalent test methods require Company approval prior to certification. 2. Name and address of the company that performed the tests, if different from the manufacturing facility. 4.9 * CERTIFICATE OF CONFORMANCE The supplier shall provide a Certificate of Conformance (C of C) that will include, as a minimum, the following information: 1. 2. 3. 4. 5. 6. 7. 8. 9. Company Purchase Order (PO) Number (if applicable) Company Part Number/Stock Number or PO Item Number Company Serial Number/Lot Number (if applicable) Quantity Shipped Drawing Number, Revision, and/or Specification, Revision, and Change Notice(s) as specified on PO to which the item was manufactured (if applicable) Manufacturer name and address Manufacturer Part Number, Serial Number, Lot Number or Batch number (if applicable) Other information as applicable (i.e., material heat number, manufacture/cure date, date of shipment, discrepancy reports) Title of the supplier’s certifying representative along with their signature (or typed name) FORM FQA-0176 (Rev 3-10) 17 A valid C of C typically contains a quality statement that states the items provided have been found acceptable to Company Purchase Order requirements. The C of C normally shall contain a signature of the authorized individual representing the supplier. Although a signature is preferred, a typed name of the supplier’s certifying representative is an acceptable substitute. (Note – A valid C of C indicates that the product/material being offered meets all the requirements in the controlling specification/drawing including applicable test methods, marking, packaging, packing, workmanship, sampling, and any other requirements). Test/inspection data shall be available upon request to substantiate the C of C. Along with other required documentation, the C of C shall accompany the product upon delivery to the Company. Note: To facilitate that all applicable C of C requirements are met, the supplier may submit a standardized C of C form (Form FQA-0170). 4.10 RETENTION OF RECORDS Unless a different period is set forth elsewhere in the Contract, Contractor shall retain all pertinent books, documents, papers, and records involving transactions related to this Contract for a period of four (4) years after final payment on this contract. Contractor may use electronic media storage in lieu of paper records if requested and approved by the Company. At the conclusion of this time period, Contractor shall make written request to ATK Aerospace Systems, addressed to the cognizant Procurement Representative, for permission to (1) destroy such records’ or (2) package and ship same to ATK Aerospace Systems; or (3) maintain said records at Contractor’s facilities; or (4) any combination of the above. Copies of such records shall be furnished to ATK Aerospace Systems upon request. 4.11 * COMPANY SOURCE INSPECTION Approval by a Company Quality Assurance representative is required prior to shipment of the material. Approval will require prior completion of inspection records, test data, shipping documents and review of hardware or material. The supplier shall notify the Company at least five (5) working days prior to presentation of material for source inspection. 4.11.1 GOVERNMENT SOURCE INSPECTION Government inspection is required prior to shipment of the material. The supplier shall promptly notify the government representative who normally services the supplier so that appropriate planning for government inspection can be accomplished. On receipt of this purchase agreement the supplier shall promptly furnish a copy of the purchase agreement to the government representative who normally services the supplier or, if none, to the nearest Army, Navy, Air Force, or Defense Supply Agency Inspection Office. In the event the representative or office cannot be located the supplier shall notify the Company immediately. A copy of the documentation bearing the Government source inspection verification shall accompany each shipment. 4.11.2 GOVERNMENT SOURCE INSPECTION (NASA CONTRACTS) All work on this order is subject to inspection and test by the Government at any time and place. The Government quality representative who has been delegated NASA quality assurance functions on this procurement shall be notified immediately upon receipt of this order. The Government representative shall also be notified 48 hours in advance of the time articles or materials are ready for inspection or test. 4.12 CRITICAL FASTENERS For part numbers identified as "critical fastener" in the purchase agreement, the supplier shall randomly select three (3) fasteners from each lot for verification of ultimate tensile strength through mechanical testing of tensile load and hardness. Testing shall be in accordance with MIL-STD-1312 or ASTM F 606 and shall be performed by an agency different from the agency that performed the testing for acceptance. Fasteners with verification test results that do not comply with the applicable product specification shall not be delivered or incorporated into assemblies to be delivered. The three fasteners subjected to verification test shall be additional to the quantity ordered. Verification test results shall be included in the acceptance data package. FORM FQA-0176 (Rev 3-10) 18 Suppliers who are responsible for design of the product to be delivered shall perform the fastener criticality analysis as specified in the purchase agreement, identify the "critical fasteners" and comply with the verification testing as stated above. 4.13 RAW CASTINGS AND FORGINGS Two samples of all raw castings and forgings are required from new or reworked dies or molds and shall be approved by the Company prior to manufacture of production parts. The samples shall be provided to the Company along with the actual results of layout inspection, radiographs, and chemical and/or physical test results. The supplier shall obtain Company approval of any change in processes, raw materials, or tooling before implementing the change. 4.13.1 HEAT TREAT CERTIFICATION The supplier shall include a heat treat certification listing the heat lot, actual chemical, physical/mechanical properties, specification used (i.e., class, type, etc.), and indicate that the method used was in compliance with that specification for all articles shipped. An authorized acceptance stamp or signature shall be affixed. A typed name submitted by the supplier is a legally acceptable substitute. 4.13.2 TENSILE TESTING Two (2) separately cast test bars, coupons, or appendages, as defined by the applicable specification or drawing, shall be submitted with each lot delivered. 4.13.3 TEST REPORTS All functional test reports shall reference the contract number, contractor’s name and address, and independent laboratory’s name and address (as applicable). Other information that shall accompany each shipment includes the following: part number, serial number or lot number, date and run time (if applicable), and summary of test results. An authorized supplier representative, either by a dated inspection stamp or signature, date, and title, shall validate all test reports. A typed name submitted by the supplier is a legally acceptable substitute. 4.14 CHEMICAL, PHYSICAL AND/OR MECHANICAL TEST REPORTS One copy of test reports indicating chemical composition, physical and/or mechanical properties including actual test data/results identifiable to each lot, batch or heat treat lot shall accompany each shipment of material. An authorized supplier representative (including subcontractor representatives), either by a dated inspection stamp or signature, date, and title, shall validate all test reports. A typed name submitted by the supplier is a legally acceptable substitute. 4.15 * CRITICAL ITEM AND KEY CHARACTERISTIC CONTROL The supplier shall establish, implement and maintain appropriate methods to control critical items, including process controls and/or inspections, where key characteristics have been identified in the Company engineering documentation. Key characteristic verification methods require Company approval prior to use. The supplier shall submit a Certificate of Compliance with each shipment attesting that all critical items and key characteristics have been verified to meet the requirements of the engineering document(s). The certification shall contain, as a minimum, a listing of the critical items and key characteristics verified, verification method used for each key characteristic, and the name of the supplier, the part number(s), purchase order number, serial number(s) (if applicable), and quantity shipped. An authorized representative of the supplier shall date and validate the certificate either by signature and title or inspection stamp. 4.16 “INTENTIONALLY OMITTED” FORM FQA-0176 (Rev 3-10) 19 4.17 * AUTHORIZATION TO SHIP (ATS) The supplier is required to provide a copy (by fax or mail) of the complete inspection planning, material, welder, and special process (heat-treat, welding, x-ray, magnetic particle, ultrasonic, plating, etc.) certifications, as specified in the purchase agreement, to the Company for review and approval in advance of the proposed ship date. Company approval is required prior to shipment. Upon approval, the Company will return a completed ATS form stamped and/or signed, signifying approval for shipment. Only if an approved ATS accompanies the packing slip will the product be received by the Company. An approved ATS does not constitute automatic product acceptance by the Company. 4.18 * FORGING DATA PACKAGE Advance approval by the Company of forging data and test reports is required prior to machining. A Forging Data Package consisting of certifications, test reports, and physical/mechanical analysis required by design shall be delivered to the Company within 10 days of the supplier's acceptance of forgings. The supplier will be notified within 7 days of acceptance and of release for machining. 4.19 ** MATERIAL CERTIFICATION The supplier shall include in the inspection data package a legible and reproducible copy of any applicable Material Certification(s). The Material Certification shall contain the following data/information: 1. A statement of conformance to applicable material requirements (material class, color, etc.). The supplier shall state the specification/drawing number and revision used. 2. Chemical, physical and/or mechanical test data that show compliance to all applicable requirements of the applicable drawing or specification. Where applicable, test data shall be actual values obtained from testing of the material (lot). Where specific test methods are required by the specification/drawing, the test methods used shall agree exactly with the methods stated in the specification/drawing. Different or equivalent test methods require Company approval. 3. Traceability information (e.g., manufacturer serial number, manufacturer lot number, batch number, heat number, etc.), as applicable. 4. Name and address of the manufacturing facility/company. 5. Name and address of the company that performed the tests, if different from the manufacturing facility. 6. Other information as applicable (i.e., manufacture/cure date, date of shipment, discrepancy reports). 4.20 ** MANUFACTURER CAGE CODE The supplier shall include the cage code of the material or component manufacturer in the acceptance documentation. 5.0 AUDITS AND SURVEILLANCE 5.1 * SUPPLIER PERFORMANCE OF AUDITS The supplier shall periodically audit its performance to determine compliance with purchase agreement requirements. Audits shall be conducted throughout the life of the contract and shall be performed by personnel not having responsibilities in the area being audited. Audits shall review all program elements for adequacy of and compliance to policies and procedures. Audits shall also review operations and manufacturing test and inspection areas for adequacy of and compliance with process controls and inspection and test methods. Audits shall also review operations in manufacturing, test and inspection areas. FORM FQA-0176 (Rev 3-10) 20 The scope of these audits shall include sub-tier material and service suppliers. Audit results shall be communicated to appropriate management. Action to correct deficiencies and follow-up to verify effectiveness shall be performed. Audit results shall be made available to the Company upon request. 5.2 COMPANY AUDIT The Company may schedule and conduct an on-site audit of the supplier's operations to assure compliance with purchase agreement requirements. Audit coverage will include examination of product quality program elements, operations, material and documents and review of supplier audit reports of sub-tier suppliers. 5.3 SOURCE SURVEILLANCE Source surveillance shall be conducted by the Company at the supplier’s facilities or where designated in the contract prior to shipment. Inspection/test and in-process inspection/test of the material defined in the contract shall be performed by the supplier and may be subject to witness by the Company. The supplier shall contact the Company prior to the start of fabrication so that mandatory in-process inspection/test points can be agreed upon. FORM FQA-0176 (Rev 3-10) 21 FORM FQA-0176 (Rev 3-10) 22