resume - Minda

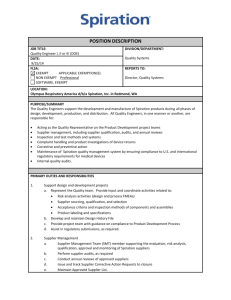

advertisement

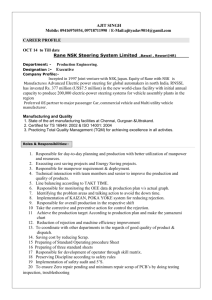

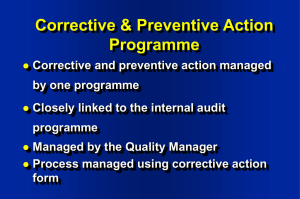

RESUME B.CHANDANA DEVI No-9, Siruthondan Stree, Mobile No : 9600259517 Email : ravilisetty_c@yahoo.co.in Near jocab school, Manavalanagar, Thiruvallur-602-002, Near chennai city. PRESENT EXPERIENCE: Daechang Seat Company India Ltd. – Chennai, An ISO/TS – 16949:2000,ISO 14001 certified Leading manufacturers of Fabricated, Sheet metal component in Car Seat frames using Presses and Robot Welding Machines for Tier 2 of Hyundai Motor India, Renault Nissan Product: Pressed & fabricated components in Car Seat Frames for Automobile Industries. Position Held: Engineer – Quality Assurance Duration: 02nd JUNE 2010 –Till date Responsibilities: Daily customer, In-house &Supplier PPM Updation All formats,Documents revision & master list updation Responsible for approving suggestions among all departments. Weekly Buizness plan & Quality improvement plan reporting to HOD. Monthly MIS Report updating & reporting to MD. Responsible for monthly Inhouse scrap register updation. Participating In the discussions of Corrective Actions as an Member of Corrective Action Team Preparation of Trends for Process Measures identified. Responsible for Internal Audit, Process Audit, Supplier Audit Implementing Requirements of Renault Nissan System (ASES) Monthly supplier Debit note reporting Supplier rating updation Monthly training report updation Daily supplier,inhouse & customer issues reporting Monthly customer,inhouse & supplier issues tracking sheet status reporting Control of Quality Lab instruments MIS Trends & Improvements display in shop floor Documents & Records control 3C & 5S internal audits action plan follow up Got Internal auditor certificate TFT Member WORK EXPERIENCE M/S Mother son Kyungshin Industrial Mother son Ltd An ISO/TS – 16949:2000,ISO 14001 certified 5- STAR & Bench mark company, Leading manufacturers of integrated wiring harness as per customer specifications,located in Chennai. Product: Integrated Wiring Harnesses Position Held: Junior Engineer – Quality Assurance Duration: 13/10/2008 to 15/05/2010 Responsibilities: Preparation of, Work Instructions, Formats and other necessary documents and records for certification. Leading a Quality team in shop floor Preparation of Trends for the Process Measures identified. Responsible for day-to-day Quality dept. activities at shop floor and taking corrective actions on non-conformances. Implementation of ‘5S’, Kaizen, 7 QC tools, Quality Circle, Waste Elimination & Value Engineering and other Quality tools in the organization. Supplier Quality rating and periodical Assessments & audits. Handling Quality Issues like Corrective & Preventive Actions based on Customer complaints, In-House Rejection &Rework, Etc. Participating In the discussions of Corrective Actions as an Active Member of Corrective Action Team Preparation of Trends for Process Measures identified. Member of Quality circle Team M/S Borg-Warner Morse TEC Murugappa Pvt. Ltd. Product: Involving in the activities of manufacturing Morse Products, Transmission Chains and Cam Sprockets and Engine Timing products (Like hydraulic tensioner) Position Held: Company aprentice - Quality Assurance Duration: 15/08/2006 to 15/08/2008 Responsibilities: As Quality inspector, I am a responsible for the all In – Process quality Activities (Like shop floor line audits, cleanliness audits etc.). Responsible for receiving inspection for inward blanks and Raw Materials. (Timing system sprockets, Tensioner plastic parts). Responsible for rejection analysis and preparing corrective action for internal and external Non –Conformities. Conducting layout inspection and layered audits. Dealing with external suppliers regarding Quality Issues. Responsible for gauges planning and Sample Preparation for new Products development works. Calibration and service of micrometers, vernier calipers, Dial Indicator,Limit gauge In- charge of Standard Room. To establish calibration methods, calibration frequency and acceptance Criteria for Instruments and gauges. Overall -Quality Monthly Reports preparation and reporting to the quality Manager. PPAP submission for new products as well as Engineering Development Order. Responsible for calibration of Instruments in Internal & External Calibration and MSA studies. Quality plan preparation and SPC studies. Faced HERO HONDA, HONDA MOTORS, MAHINDRA& MAHINDRA, TVS, FORD, SUZUKI, and ISO/TS16949: 2002 audits. Fast Response for customer complaint. Customer return parts analysis and finding route cause for failure of product. Knowledge & operating of Metallurgical Equipment. Knowledge about PPM activities. Knowledge about DMS (Daily Management System) activities. Knowledge about POKO-YOKE. KAIZEN implementation and also 5’S activities (I was selected best kaizen award2008). Training Undergone 1. ISO / TS 16949 Internal Audit 2. ISO 14001 EMS Internal Audit 3. 6Sigma Awareness Training 4. Production Management 5. MSA Training 6. PPAP/APQP 7. ASES-Renault Nissan Requirement 8. SPC 9. 7QC Tools 10. FMEA 11. Fire Safety training Salary Detail Salary Drawn CTC – Rs. 2,73,480 / Annum Salary Expected CTC– Rs. 3,33,480 /Annum Location preferred –Chennai Academic profile Certificate S.S.C certificate (From Board of secondary school certificate) 7th day adventist high.school Edepalli Machilipatnam.(A.P) Date of Awarded Performance 2003 Diploma in Electronics &Communications Engg SVL Polytecnic College, 2006 class (State Board of Technical Education Andhra Pradesh-India), Chilakalapudi, Machilipatinam,Krishna (District)-Andhra Pradesh. Comments 53% ------ 69.21% First Electronics project done HIGHWAYS SPEED CHECKER While driving on Highways, motorists should not exceed the maximum speed limit permitted for their vehicle. How ever, accidents keep on occurring since the drivers violating the speed limit precautions, as they tend to ignore their speedometers. This speed checker will come handy for the highway traffic police as it will not only provide a digital display in accordance with a vehicle’s speed but also sounds an alarm, if the vehicle exceeds the permissible speed for the highway. Personal Profile Date of birth and age Fathers name Nationality Sex Marital status Languages known : 19.07.1987 (Age-27) : R.Venkateswara rao : Indian : Female : Married : Telugu, Tamil, English, Hindi. Date : Place : (R.CHANDANA DEVI)