12449 Demonstrate knowledge of gas combustion, burners

advertisement

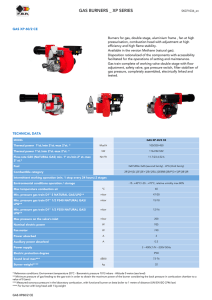

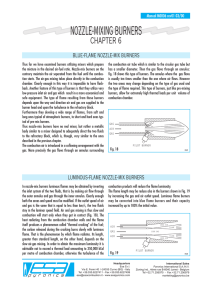

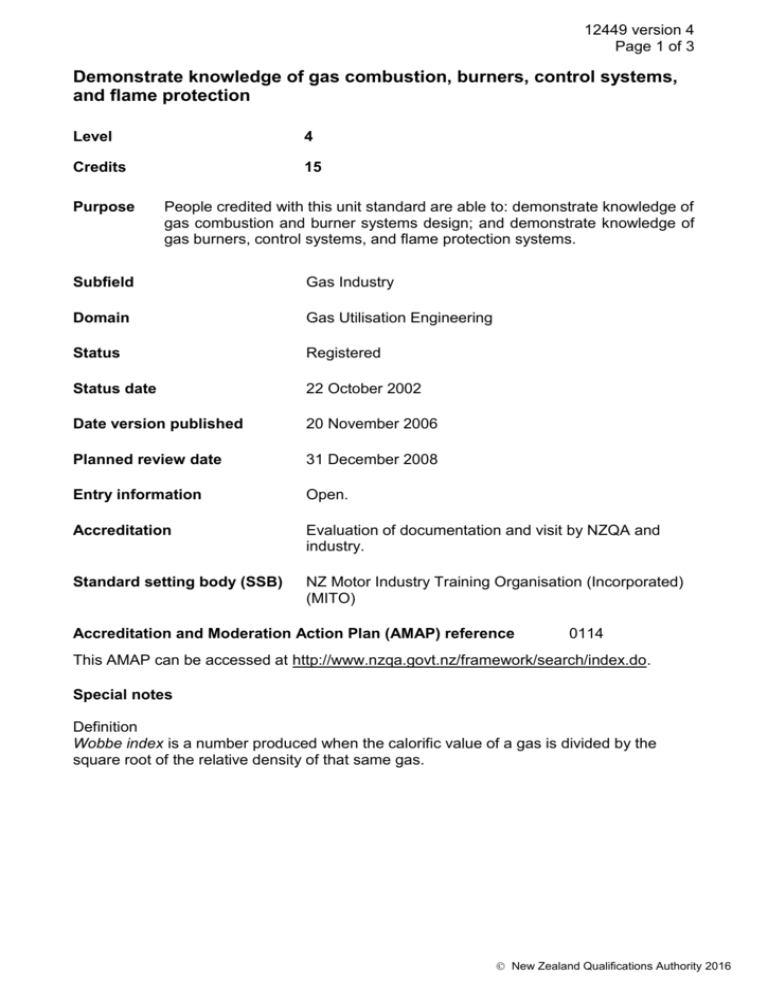

12449 version 4 Page 1 of 3 Demonstrate knowledge of gas combustion, burners, control systems, and flame protection Level 4 Credits 15 Purpose People credited with this unit standard are able to: demonstrate knowledge of gas combustion and burner systems design; and demonstrate knowledge of gas burners, control systems, and flame protection systems. Subfield Gas Industry Domain Gas Utilisation Engineering Status Registered Status date 22 October 2002 Date version published 20 November 2006 Planned review date 31 December 2008 Entry information Open. Accreditation Evaluation of documentation and visit by NZQA and industry. Standard setting body (SSB) NZ Motor Industry Training Organisation (Incorporated) (MITO) Accreditation and Moderation Action Plan (AMAP) reference 0114 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes Definition Wobbe index is a number produced when the calorific value of a gas is divided by the square root of the relative density of that same gas. New Zealand Qualifications Authority 2016 12449 version 4 Page 2 of 3 Elements and performance criteria Element 1 Demonstrate knowledge of gas combustion, and burner systems design. Performance criteria 1.1 The combustion characteristics of gas are defined and related to gas burner systems design in terms of the principles of physics and chemistry. Range 1.2 Heat transfer principles are defined and related to gas burner systems design in terms of industry usage. Range 1.3 conduction, convection, radiation. The requirements for combustion are defined and their role explained in terms of physical laws. Range 1.4 Charles’ law, Boyle’s law, calorific value, gas composition, oxygen requirements, Wobbe index. fuel source, ignition source, oxygen. Causes of incomplete combustion are explained and the potential hazards identified in terms of industry practice. Range lack of oxygen, chilling. Element 2 Demonstrate knowledge of gas burners, control systems, and flame protection systems. Performance criteria 2.1 Types of gas burner are described in terms of usage in domestic and industrial environments. Range 2.2 Component parts of burners are described in terms of purpose and function. Range 2.3 pre-aerated burners, post-aerated burners, pre-mix burners, forced draught burners, radiant burners. injector, primary air port, aeration control shutter, venturi, venturi throat, throat restrictor, mixing tube, burner head, burner ports, retention ports. Air injection systems are described in terms of natural draught and forced draught. New Zealand Qualifications Authority 2016 12449 version 4 Page 3 of 3 2.4 Faults in burner operation are described in terms of causes, and the steps to prevent them are described in accordance with company procedures. Range 2.5 unstable flame pattern, unsuitable gas flow rate, inadequate air supply, excessive air supply, linting. Component parts of control systems for gas burners are described in terms of purpose, function, and industry usage. Range isolation valves, control valves, governor, weep line, test cock, thermostat. 2.6 Control systems for gas burners are described in terms of pressure operated systems and electrically operated systems. 2.7 Types of flame protection system for gas burners are described in terms of purpose and industry usage. Range bimetallic, vapour pressure, thermo-electric, flame conduction and rectification, photo-electric. Please note Providers must be accredited by the Qualifications Authority, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by the Qualifications Authority before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the NZ Motor Industry Training Organisation (Incorporated) (MITO) info@mito.org.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016