R-Series Oil Burners

advertisement

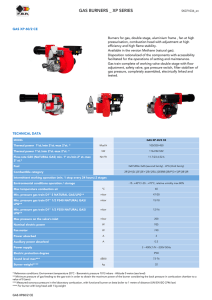

RL06 Oil Burner Reprint NP 2/26/02 1:07 PM Page 1 R-Series Oil Burners Maximum Performance. Minimum Maintenance. Oil Riello Burners – a world of experience in every burner we sell Across North America and the world over, Riello sets the standard in reliable, high-efficiency, low-maintenance burner technology. With burner capacities from 38 thousand to more than 70 million Btuh, Riello oil, gas and dual-fuel burners deliver unbeatable performance across the full range of residential and commercial heating applications, as well as in light industrial processes. Gas Quality engineered for reliability, combined with fuel and power efficiency, Riello burners are environmentally friendly, and easy to install and service – all hallmarks of Riello’s advanced burner technology. With headquarters in Legnago, Italy, Riello has been manufacturing premium quality burners for over 80 years. Today, to meet its customers’ needs, Riello employs more than 2,000 people across four continents, with a sales and support network that spans over 60 countries. Dual-Fuel Throughout the United States and Canada, our staff and independent sales and support network are dedicated to providing applications engineering support, commissioning, hands-on training, ongoing technical assistance, and after-sales service. Riello Burners – delivering reliable combustion solutions for our customers in North America and around the world. Low NOx Quality engineered for the North American market to Riello’s proven world-class standard, R-Series oil burners are built for maximum uptime. These compact burners are based on a simple, integrated design that provides high-efficiency, low-noise operation while significantly reducing fuel and maintenance costs. And Riello R-Series oil burners offer a host of standard features – like compact, light-weight, die-cast aluminum construction; an integrated control panel, and innovative slidebars that make installation and servicing easy. Reliable Combustion Solutions 35 Pond Park Road Hingham, Massachusetts U.S.A. 02043 1-800-4-RIELLO 1-800-474-3556 www.riello-burners.com 2165 Meadowpine Blvd Mississauga, Ontario Canada L5N 6H6 Riello R-Series oil burners are available in firing rates from 2.4 to 65.6 gph, to handle a broad range of commercial, industrial and process applications. Offered in a variety of configurations with optional accessories, our RL models deliver uncompromising performance and reliability. RL06 Oil Burner Reprint NP 2/26/02 1:07 PM Page 3 1 RL/M RL/2 (Not in main view) The servomotor on the RL/M is designed to accept all common types of modulating signals, for maximum control flexibility. 70-190 Modulating Oil • 5.4 – 65.6 gph 70-130 2-Stage Oil • 6.9 – 41.6 gph 10 2 Available in both full modulating and low-high, 2-stage firing configurations, Riello R-Series oil burners come with standard features that applications such as hot water and steam boilers, 7 Camnetic Regulating Assembly A characterized, fully adjustable cam assembly with nine lockable adjustment screws and automatic air damper. Provides accurate fuel/air ratio control throughout the firing range for highly reliable combustion and excellent repeatability. deliver high efficiency and reduced fuel consumption for thermal oil heaters and other light industrial processes Advanced Servomotor 3 with high-capacity requirements. 3 Unique Combustion Head Design Specifically designed for lower-than-standard emissions, the Riello combustion head is available in various lengths to handle a wide range of applications. 2 9 4 The RL burner’s factory pre-wired, integrated control panel offers user-friendly operation and ease of service while contributing to an extremely compact overall design. Remote panels are available with Siemens, Honeywell or Fireye controls. 4 5 High-efficiency reverse-incline fan The burner’s self-cleaning fan blades are set at a reverse incline. The result is high static pressure capability combined with low-noise operation. A high-efficiency fan motor provides for low power consumption and reduced operating costs. 8 6 Low-High 2-Stage Firing Integrated Control Panel The 2-stage firing Riello RL/2 is equipped with a burner-mounted oil fuel train for easy field installation. 7 6 RL70/M Service slidebars All RL burners incorporate innovative slidebars which enable the burner assembly to be pulled outwards on two guides, allowing quick access to the combustion head for easy installation and servicing. The result is lower maintenance costs. Die-cast aluminum chassis Riello’s quality engineered, die-cast aluminum construction allows for the RL’s remarkably compact design, light weight and ease of installation. 9 Flame viewing window An accurately positioned flame viewing window provides for easy flame monitoring. Insulated air intake housing Sound deadening material incorporated within the air intake housing further contributes to the RL’s low-noise operation, even at full output. 5 8 10 Exterior drawer assembly adjustment screw An innovative feature, the RL burner’s exterior drawer assembly adjustment screw allows service personnel to quick-adjust insertion depth, fine tuning air flow pattern for shaping flame geometry. RL06 Oil Burner Reprint NP 2/26/02 1:08 PM Page 5 RL/2 RL/M 28-50 2-Stage • 2.6 – 16 gph 9 RL38/2 4 28-50 Modulating • 2.4 – 16 gph 7 Riello R-Series oil burners come standard 2 in a low-high, 2-stage firing configuration, 5 with a full modulating version also available. The burner’s self-cleaning fan blades are set at a reverse incline. The result is high static pressure capability combined with low-noise operation. A high-efficiency fan motor provides for low power consumption and reduced operating costs. Both models are quality engineered for high reliability in applications such as hot water and steam boilers, thermal oil heaters and other light industrial processes with low1 capacity requirements. High-efficiency reverse-incline fan 6 Insulated air intake housing Sound deadening material incorporated within the air intake housing further contributes to the RL’s low-noise operation, even at full output. 8 7 Die-cast aluminum chassis Riello’s quality engineered, die-cast aluminum construction allows for the RL’s remarkably compact design, light weight and ease of installation. 8 3 Flame viewing window An accurately positioned flame viewing window provides for easy flame monitoring. 9 Full Modulating Assembly Exterior drawer assembly adjustment screw An innovative feature, the RL burner’s exterior drawer assembly adjustment screw allows service personnel to quick-adjust insertion depth, fine tuning air flow pattern for shaping flame geometry. 6 A fully adjustable regulating assembly is also available on the RL/M, providing accurate fuel/air ratio control throughout the firing range. 5 1 Integrated Control Panel The RL burner’s factory pre-wired, integrated control panel offers userfriendly operation and ease of service while contributing to an extremely compact overall design. Remote panels are available with Siemens, Honeywell or Fireye controls. 2 Service Slidebars All RL burners incorporate innovative slidebars which enable the burner assembly to be pulled outwards on two guides, allowing quick access to the combustion head for easy installation and servicing. The result is lower maintenance costs. 3 2-Stage Oil Regulating Assembly The Riello RL/2 comes standard with a burner-mounted 2-stage oil fuel train for easy field installation and simple operation. 4 Unique Combustion Head Design Specifically designed for lowerthan-standard emissions, the Riello combustion head is available in various lengths to handle a wide range of applications. RL06 Oil Burner Reprint NP 3/6/02 11:08 AM Page 7 Specifications R L L i g h t - O i l Fo r c e d - D r a f t B u r n e r s Dimensions RL/2 All units are in inches Combustion Air Motor HP Amperage Draw Sound Levels dBA Max. Chamber Pressure (“w.c.) @ high fire 28 2.6 - 9.0 120/1/60 1/2 5.2 68.0 1.5 38 3.2 - 12.2 120/1/60 or 230-460-575/3/60 1/2 or 3/4 5.2 / 3.2 / 1.6 / 1.3 70.0 1.6 50 4.0 - 16.0 230-460-575/3/60 3/4 3.2 / 1.6 / 1.3 75.0 1.2 70 6.9 - 22.4 230-460-575/3/60 1 1/2 4.8 / 2.8 / 2.3 68.0 2.1 100 9.6 - 32.0 230-460-575/3/60 2 1/2 6.7 / 3.9 / 3.2 70.0 2.5 13.1 - 41.6 230-460-575/3/60 3 8.8 / 5.1 / 4.1 70.0 3.4 B C D E F-F 1 * G H I-I 1 J 1823/32 – – 1821/32 1813/32 81/2 - 1313/16 51/2 1327/32 2615/32 - 313/4 21/16 130 38 1823/32 – – 1821/32 1813/32 81/2 - 1313/16 51/2 1327/32 2615/32 - 313/4 21/16 28 2.4 - 9.0 120/1/60 1/2 5.2 68.0 1.5 50 1823/32 – – 1821/32 1813/32 81/2 - 1313/16 531/32 1327/32 2615/32 - 313/4 21/16 38 2.7 - 12.2 230-460-575/3/60 3/4 3.2 / 1.6 / 1.3 70.0 1.6 70 2227/32 1121/32 113/16 2127/32 2625/32 927/32 - 155/32 71/16 1615/16 377/16 - 423/4 – 50 3.5 - 16.0 230-460-575/3/60 3/4 3.2 / 1.6 / 1.3 75.0 1.8 100 23 12 11 21 26 9 7 15/16 16 377/16 - 423/4 – 70 5.4 - 22.4 230-460-575/3/60 1 1/2 4.8 / 2.8 / 2.3 75.0 2.3 130 245/8 135/16 115/16 2127/32 2625/32 927/32 - 155/32 77/16 1615/16 377/16 - 423/4 – 100 9.0 - 32.0 230-460-575/3/60 2 1/2 6.7 / 3.9 / 3.2 77.0 1.8 130 11.2 - 41.6 230-460-575/3/60 3 8.8 / 5.1 / 4.1 78.0 3.2 190 12.8 - 65.6 230-460-575/3/60 5 1/2 15.8 / 9.1 / 7.3 83.9 0.5 27/32 25/32 27/32 - 15 5/32 1/16 – – 1821/32 1813/32 915/32 - 1313/16 51/2 1327/32 2615/32 - 313/4 21/16 38 1823/32 – – 1821/32 1813/32 915/32 - 1313/16 51/2 1327/32 2615/32 - 313/4 21/16 50 18 – – 18 18 9 5 13 26 21/16 70 261/8 1121/32 1415/32 2127/32 2625/32 1023/32 - 155/32 71/16 1615/16 377/16 - 423/4 – 100 26 12 14 21 26 10 7 16 37 – 130 273/4 135/16 1415/32 2127/32 2625/32 1023/32 - 155/32 77/16 1615/16 377/16 - 423/4 – 190 32 1413/32 1719/32 2127/32 2713/32 149/16 83/4 1615/16 433/8 – 23/32 1/8 9/32 21/32 15/32 13/32 27/32 15/32 25/32 - 13 23/32 13/16 31/32 - 15 5/32 27/32 1/16 15/32 15/16 7/16 - 31 3/4 - 42 3/4 (1) Ratings based on 140,000 Btu/Gallon for No.2 fuel oil. ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ Direct-drive pump Drawer & nozzle assembly with diffuser Nozzle(s) Main safety shut-off valve 1-stage valve 2nd stage shut-off valve Supply shut-off valve Return shut-off valve Hydraulic cylinder for air regulation Camnetic regulating assembly Vacuum pressure gauge (burner mounted) ■ ■ 2 ■ ■ ■ Siemens LAL 2.25 flame safeguard Starter with overload Terminal strip On-off switch High / low fire hold switch Auto / manual / off switch Manual firing rate switch PID modulating controller ■ ■ ■ ■ ■ Siemens LAL 2.25 flame safeguard Honeywell RM7800 Series flame safeguard Fireye E-110 flame safeguard Fireye MEC120 flame safeguard Starter with overload Terminal strip On-off switch Fuses Indicating lights: Power on Main flame on Flame failure ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ Alarm horn with silencing switch Additional light Set of dry contacts Panel front-mounted flame safeguard display 2-position switch (maintained contact) ■ ■ ■ ■ ■ General Combustion Chamber Pressure ("w.c) RL50/2 3.5 RL38/2 3.0 RL28/2 2.5 2.0 1.5 1.0 0.5 0 - 0.5 RL70/2 3.5 3.0 2.5 2.0 1.5 1.0 0.5 0 - 0.5 Capacity (GPH) 2 (MBTUH) 300 4 3 400 500 5 600 700 7 6 8 9 10 11 12 13 14 15 16 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200 2300 800 RL50/M 3.5 2.0 1.5 1.0 0.5 0 - 0.5 (MBTUH) 300 4 3 400 500 5 600 700 7 6 800 8 9 10 11 12 13 14 15 16 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200 2300 Combustion Chamber Pressure ("w.c) RL28/M 2 8 12 16 20 1,120 1,680 2,240 2,800 24 28 3,360 3,920 32 36 40 4,480 5,040 5,600 RL190/M 5.5 3.0 Capacity (GPH) 4 560 6.0 RL38/M 2.5 Capacity (GPH) (MBTUH) 5.0 4.5 RL100/M RL130/M 4.0 RL70/M 3.5 3.0 2.5 2.0 1.5 1.0 0.5 Reference Conditions Ambient temperature: 68ºF (20ºC) Barometric pressure: 394”w.c. Altitude: 329 ft. a.s.l. 0 - 0.5 Capacity (GPH) 4 (MBTUH) 560 R-Series burners are UL, cUL and MEA320-01-E (New York) approved. 8 12 16 20 24 28 32 36 1,120 1,680 2,240 2,800 3,360 3,920 4,480 5,040 40 44 48 52 56 60 64 5,600 6,160 6,720 7,280 7,840 8,400 8,960 Full Modulation RL70/2 - RL130/2 Combustion air motor with reverse-incline fan Service slidebars Photo cell / scanner Direct spark ignition Burner mounted fuel system (pre-piped & tested) Fuel ignition transformer(s) Flame retention combustion head Servomotor (fuel / air ratio adjustment) Flame inspection window Air pressure switch Fan pressure test point Oil System RL130/2 RL100/2 4.0 RL28/2 - RL50/2 (1) F i r i n g R at e s (3) A separate 120/1/60 control voltage supply is required. Low - High Standard Features - RL Models * F1 Length with combustion head extension. Not available on the RL190/M. 4.5 (2) Other voltages available on request. Integrated Control Panel 5/16 Remote Panel (Optional) 9/32 Options 19/32 RL/M A 1823/32 Combustion Chamber Pressure ("w.c) Voltage(2) (3) RL/2 28 RL/M 28 Combustion Chamber Pressure ("w.c) Capacity (GPH)(1) Model (1) Forward-incline fan on RL190/M. ■ ■ ■ ■ 2 ■ ■ ■ ■ ■ ■ RL28/M - RL50/M RL70/M - RL190/M ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■(1) ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ 1 ■ ■ ■ 1 ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ Optional ■ ■ Optional ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■