2011-10-21-Belfast-Unit-3-Materials-and-their

advertisement

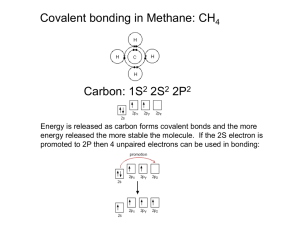

Materials and their uses Structure of Materials The specification states; Materials behave as they do because of their structure; the way their atoms and molecules fit together You need to know; - how the internal structure of a material influences the way it behaves - ways in which properties materials can be modified by altering the structure of the material Using Materials • The first record of the use of salt dates back to around 6050 BC. • It was used as part of Egyptian religious offerings • In ancient Rome salt was used as a method of payment (the origin of the word salary) • Gold has been highly valued since prehistoric times. • It was associated with beauty, power and wealth. Around 1300 BC Egyptian hieroglyphs from as early as 2600 BC describe gold as ‘more plentiful than dirt’ Around 2000 BC • The word diamond derives from the Greek word ‘Adamas’ meaning unconquerable and indestructible • Diamonds are thought to have been mined in India around 800 BC • Why choose the three materials? salt gold diamond Materials behave as they do because of their structure; the way their atoms and molecules fit together Properties of Materials We have known many of the properties of materials for thousands of years Metals are shiny, they have a high melting point, they are malleable, ductile, they are insoluble and they conduct electricity* Salt is crystalline, it is soluble in water, it has a high melting point and it conducts electricity in solution* Diamonds are crystalline, they have a high melting point, they are insoluble and they do not conduct electricity* *All later discoveries Why? • We know how materials behave – their properties •The next question is why? •An important development in our scientific knowledge pointed to the answer i.e. The understanding that electricity is a flow of charged particles The flow of charge is called the current and it is the rate at which electric charges pass though a conductor. The charged particle can be either positive or negative. Conducting electricity Two types of materials that we know conduct electricity are Metals Salt The search to find their ‘charged particles’ eventually led to an understanding of the structure and properties of materials The Atom Bohr’s Atom Metals Metals conduct electricity They have charged particles which are free to move Each atom loses control of its outer shell electron resulting in a lattice of positive ions surrounded by a ‘sea’ of electrons Metallic bonding is the result of strong electrostatic attraction between the positive core and the negative ‘sea’ of electrons The strength of the bond gives metals their high melting point The melting point of gold is 1064oC • Metals objects are formed by casting • The process is controlled by temperature and other factors • As the metal cools small crystals (grains) appear • The crystals grow until they form a solid mass of small crystals Crystals in metals • In a crystal the molecules of the material lock together in a regular and repeating pattern. If a crystal is allowed to grow undisturbed, it will form regular shapes such as cubes, or hexagonal columns. The type of substance and how its molecules interlock determine the shape of the crystal Grains • When the molten metal solidifies, different regions crystallise at the same time • The crystalline areas are known as ‘grains’ • Eventually growing grains meet at grain boundaries • At these boundaries there are can be atoms which do not fit into the crystal structure dislocation Properties of metals •Hard but malleable and ductile – metals can be hammered into sheets or drawn into wires because blocks of atoms or grains can slip over one another. the block slip theory – when stress is applied to the structure, blocks of atoms become displaced as they slip past one another •Conduct electricity because the delocalised electrons are free to move towards the positive terminal •Are shiny because as light shines on the metal the electrons absorb energy and jump temporarily to a higher energy. When the electron falls back to its lower level the extra energy is emitted as light Flame tests Lithium Red Sodium Yellow Potassium Lilac Calcium Brick red Barium Green Flame tests Aurora Borealis Cold Working Metals can be ‘cold –worked’ – forced into new shapes at a low temperature Dislocations occur at the grain boundaries as it is worked. The more dislocations a metal has, the more they get in the way of each other The metal becomes stronger but less ductile – more brittle Annealing • Annealing is a treatment used to restore softness and ductility to metals •The metal is put in a furnace to soften the metal •It is then allowed to cool slowly so that new crystals form and there are fewer dislocations Salt Salt conducts electricity when it is dissolved in water There must be charged particles which are free to move Chlorine 35Cl 17 Ions Sodium atom Chlorine atom 11 protons + 11 electrons 17 protons + 17 electrons +11 -11 = 0 Sodium ion +17 -17 = 0 Chlorine ion 11 protons + 10 electrons 17 protons + 18 electrons +11 - 10 = +1 +17 -18 = -1 Sodium chloride crystal Ionic Bonding As with metals the strong electrostatic attraction between the positive and negative ions results in ionic compounds having a high melting point (salt melts at 808oC) Ionic compounds conduct electricity when in solution as the ions (the charged particles) are free to move to the positive and negative terminals Diamond • Diamond does not conduct electricity Diamond consists of atoms of carbon bonded together to form a material with a very high melting point It has no charged particles An uncut diamond Bonding in diamond Carbon atoms are bonded by sharing electrons in a covalent bond • Covalent bonds form when outer shell electrons are attracted to the nuclei of more than one atom •Both nuclei attract the electrons equally so keeping them held tightly together Giant Covalent Bonding Repeating crystal lattice High melting point due to strength of covalent bonds (3550oC) Cannot conduct electricity as it has no free charged particles Graphite Like diamond graphite has strong covalent carbon to carbon bonds and a high melting point (3720OC) Graphite conducts electricity The bonds between the covalently bonded sheets of carbon are weak bonds and the electrons are easily attracted to a positive terminal Fullerenes C60 Buckyball Carbon nanotube Discovered in 1985 Fullerenes are resilient to impact and deformation. This means, that squeezing a buckyball and then releasing it would result in its popping back in shape. Or ,if it was thrown against an object it would bounce back Buckyballs are also extremely stable in the chemical sense Their hollow structure allows other atoms to be carried within them What decides the type of bond? Elements on the left of the periodic table Sodium 2.8.1 (groups 1 & 2) tend to lose electrons Magnesium 2.8.2 Elements on the right (groups 7 & 8) tend to gain electrons Fluorine 2.7 Oxygen 2.6 Electronegativity is a measure of the tendency of an atom to attract electrons in a bond – the greater the electronegativity, the greater the ability to attract the electrons Electronegativity increases going across a period and going up a group losers gainers Bond Type IONIC Metal non-metal Non – metal non –metal COVALENT Metal metal Low electronegativity METALLIC High electronegativity Polymers The largest group of covalent compounds are polymers Polymers are long carbon chains sometimes with different functional groups added and all held together by covalent bonds The bonding in a polymer chain is strong covalent bonding The bonding between chains can create either thermsoftening plastics or thermosetting plastics Thermoplastics • In thermosoftening plastics like poly(ethene) the bonding is like ethane except there are lots of carbon atoms linked together to form long chains. They are moderately strong materials but tend to soften on heating and are not usually very soluble in solvents. Can be recycled A thermosoftening plastic Weak bonds between chains • Thermosoftening heat: softens hard, solid cool: harden soft, pliable • These can be heated enough to be reshaped. This stretches the cross links. When cooled in the stretched state they stay stretched and retain the new shape • If reheated the chains are free to slide back to their original shape Thermoset plastics • Thermosetting plastic structures like melamine have strong 3D covalent bond network they do not dissolve in any solvents and do not soften on heating and are much stronger than thermoplastics They do not lend themselves to recycling like thermosoftening plastics which can be melted and remoulded. A thermosetting plastic Covalent bonds between chains) • Thermosetting Cool: harden during manufacture warm, pliable permanently hard • Both thermoplastics and thermoset plastics can be strong, tough, rigid and stable towards chemical attack Bonds between atoms are strong covalent bonds so they do not conduct electricity •Bonds between chains are weak intermolecular bonds •When plastics melt or dissolve it is the intermolecular forces that are broken so the different parts can slide past one another NAME Uses of thermosets PROPERTIES USES Epoxy resin Good electrical insulator, hard, brittle unless reinforced, resists chemicals well adhesives, bonding of other materials Melamine formaldehyde Stiff, hard, strong, resists some chemicals and stains Laminates for work surfaces, electrical insulation, tableware Polyester resin Stiff, hard, brittle unless laminated, good electrical insulator, resists chemicals well bonding of other materials Urea formaldehyde Stiff, hard, strong, brittle, good electrical insulator Electrical fittings, handles and control knobs, adhesives NAME Uses of thermoplastics PROPERTIES USES Polycarbonate high impact resistance, temperature resistance and optical properties lighting lenses,sunglass/ eyeglass lenses, safety glasses, compact discs,DVDs automotive headlamp lenses, lab equipment and drinks bottles Polyamide (Nylon) Creamy colour, tough, fairly hard, resists wear, selflubricating, good resistance to chemicals and machines well Bearings, gear wheels, hinges for small cupboards, curtain rail fittings and clothing Polymethyl methacrylate (Acrylic) Stiff, hard but scratches easily, durable, brittle in small sections, good electrical insulator, machines and polishes well Signs, covers of storage boxes, aircraft canopies and windows, covers for car lights, wash basins and baths Polystyrene: - conventional Light, hard, stiff, transparent, brittle, with good water resistance Toys, especially model kits, packaging, castes for televisions, 'plastic' boxes and containers Cold drawing • Cold drawing is the process of stretching out a polymer fibre to line up the chains • Cold drawing is used to increase a polymers’ strength. Crystalline Plastics • A very strong material can be produced by arranging the molecules of a plastic to produce a highly ordered material. • This material is sometimes called oriented plastic describing the way the molecules line up • A recent example of such polymer engineering is a substance called ‘spectra’ produced by an American chemical company. Surgeons • Spectra fibres have enormous gloves made of strength and yet are very flexible. fabric woven with oriented plastic Ceramics • Ceramics are materials that include glass, enamel, concrete, cement, pottery, brick, porcelain, and chinaware. Ceramics can be defined as inorganic, non metallic materials. They are typically crystalline in nature and are compounds formed between metallic and non metallic elements such as aluminium and oxygen calcium and oxygen , and silicon and nitrogen • Ceramics are hard and strong so are used as structural material such as bricks in houses, stone blocks in the pyramids •but not in conditions of tensile stress because they are brittle (low tensile strength) •Most ceramics do not conduct electricity but this depends on the type - chromium dioxide does, silicon dioxide is a semi– conductor, aluminium dioxide does not Bonding in ceramics • Bonding are usually ionic as in magnesium oxide or aluminium oxide in which the ions are arranged in a regular repeating pattern - a giant lattice 2 Combine with 3 To give • Bonding can also be covalent e.g. in silicon carbide or silicon nitride • The structure is a giant covalent lattice Semi Conductors A chip An LED A transistor Semiconductors have had a monumental impact on our society. You find semiconductors at the heart of microprocessor chips as well as transistors. Anything that's computerized or uses radio waves depends on semiconductors. Silicon is a semi conductor Silicon bonding Silicon giant covalent lattice •Generally in a giant covalent lattice all the electrons are tied into the bonds and are not free to conduct electricity •In a semiconductor (like silicon) if electrons get enough energy they escape from the atom. Heat or light provides this energy •Given enough energy electrons can escape to the conduction band (like the delocalised electrons in metals) and are free to move and conduct electricity Conduction in semiconductors Delocalised electrons Electrons in filled shells Doping silicon: diodes and transistors You can change the behaviour of silicon and turn it into a conductor by doping it. In doping, you mix a small amount of an impurity into the silicon crystal. There are two types of impurities 1. phosphorus or arsenic – called N-type 2. boron or gallium – called P-type N type semiconductor Si P Contaminated by phosphorus which has 5 outer electrons 4 of these are involved in the covalent bonds One phosphorus electron has nothing to bond with and is free to move around. It needs little energy to jump to the conduction band It takes very little impurity to create enough free electrons to allow an electric current to flow P type semiconductor Si Contaminated by boron which has 3 outer shell electrons B A fourth electron is taken from a silicon atom creating a positive hole This silicon takes an electron from another silicon and so on …............. The ‘positive hole’ is moving through the semi conductor Uses of semi conductors A diode is the simplest possible semiconductor device. A diode allows current to flow in one direction but not the other. You may have seen turnstiles at a stadium or a subway station that let people go through in only one direction. A diode is a one-way turnstile for electrons. When you put N-type and P-type silicon together you get a very interesting phenomenon that gives a diode its unique properties. Amorphous Materials An amorphous solid is a solid in which there is no long-range order of the positions of the atoms. For instance, common window glass is an amorphous ceramic, many polymers (such as polystyrene are amorphous, and even foods such as candy floss are amorphous solids. • When glass is broken the edges of the piece have a range of shapes and sizes • If a crystal is broken it cleaves along the grain of the crystal • This difference in behaviour is due to the fact that glass is an amorphous solid - its particles are jumbled up •Amorphous solids behave more like liquids than solids in terms of their structure and are sometimes referred to as ‘supercooled liquids’ – liquids cooled below their melting point This type of solid has no definite melting point but softens as it is heated (like glass or some plastics) and can be shaped by heating Glass • Glass is an amorphous material usually produced when the viscous molten material cools very rapidly to below its melting point without sufficient time for a regular crystal lattice to form Amorphous materials are often prepared by rapidly cooling molten material, such as glass. The cooling reduces the mobility of the material's molecules before they can pack into a more crystalline state. Amorphous materials can also be produced by additives which interfere with the ability to crystallize. For example addition of soda to silicon dioxide results in window glass. What is glass? The term glass refers to amorphous oxides, and especially silicates (compounds based on silicon and oxygen). Ordinary soda-lime glass, used in windows and drinking containers, is created by the addition of soda and lime (calcium oxide) to silicon dioxide. Without these additives silicon dioxide will (with slow cooling) form quartz crystals, not glass Properties of glass - Solid and hard material - Disordered and amorphous structure - Fragile and easily breakable into sharp pieces - Transparent to visible light - Inert and biologically inactive material. - Glass is 100% recyclable and one of the safest packaging materials due to its composition and properties Tempered/ heat toughened glass Tempering: Tempered safety glass is a single piece of glass that gets tempered using a process that heats, then quickly cools the glass to harden it. The glass is heated in a furnace and cooled quickly. The outside hardens but the inside remains fluid and flows out to the edges compressing the molecules together. The tempering process increases the strength of the glass from five to 10 times that of untempered glass. Advantages of toughened glass • Toughened glass or tempered glass is a type of safety glass that has increased strength and will usually shatter in small, square pieces when broken. It is used when strength, thermal resistance and safety are important considerations. Sintering • In the sintering and pressing process, first the glass is ground to a fine powder and mixed with a binder. The mixture is portioned out into a metal die and pressed. The pressed article is removed from the die and fired in a kiln to the sintering temperature, 700900°C. The result is hard, somewhat porous glass. It is not transparent or does not otherwise look similar to molten glass. Composites • Composites are combinations of materials with different properties • The parts of the composite retain their identity and do not dissolve or completely merge together • They act together Reinforced concrete fibreglass Uses of composites Glass- ceramic composite • Glass-ceramic is a mechanically very strong material and can sustain repeated and quick temperature changes up to 800 – 1000oC. The Future •Nanotechnology is the art and science of manipulating matter at the nanoscale (down to 1/100,000 the width of a human hair) to create new and unique materials and products. The opportunities to do things differently with nanotechnology have enormous potential to change society. Dust mite and gears produced by nanotechnology Sunscreen - Many sunscreens contain nanoparticles of zinc oxide or titanium oxide. Older sunscreen formulas use larger particles, which is what gives most sunscreens their whitish color. Smaller particles are less visible, meaning that when you rub the sunscreen into your skin, it doesn't give you a whitish tinge. Clothing - Scientists are using nanoparticles to enhance your clothing. By coating fabrics with a thin layer of zinc oxide nanoparticles, manufacturers can create clothes that give better protection from UV radiation. Some clothes have nanoparticles in the form of little hairs or whiskers that help repel water and other materials, making the clothing stain-resistant. Antimicrobial bandages - Scientist Robert Burrell created a process to manufacture antibacterial bandages using nanoparticles of silver. Silver ions block microbes' cellular respiration . In other words silver smothers harmful cells, killing them. The Future • Nanotechnology involves using nanoparticles of different elements or compounds to alter the properties of materials • e.g. - developing cheap, disposable solar panels by developing specialist inks containing silicon nanoparticles - nanodevices capable of detecting cancer and other diseases at the earliest stages, pinpointing the location of the disease, delivering effective drugs only to the site of the disease and monitoring the progress of the treatment - nanocatalytic fuel cells capable of powering a laptop with the equivalent amount of alcohol as 2 or 3 drinks - implants made of materials that will bond with natural tissues and not be rejected by the body especially neural and retinal tissue