POLYMER

advertisement

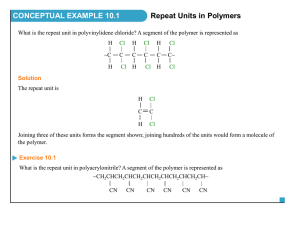

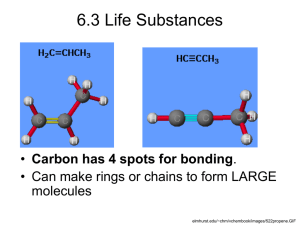

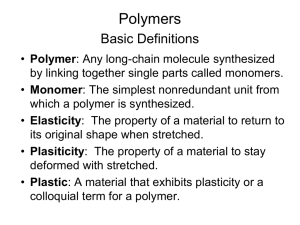

Poly mers Many Smallest repeated units Intramolecular = covalent bond = 1ry bond Intermolecular = 2ry bond Definitions: Polymer: A long chain organic molecule consisting of many repeating units called monomers or mers. Monomer (mer): Smallest repeating unit in a polymer. Mono = Single Mer term is derived from the Greek word meros (parts). Oligomer: Is a short polymer composed of 10 mers. Polymerization reaction: The reaction by which the monomer units become chemically linked together to form high molecular weight molecule (polymer). Homopolymer: One type of monomer Copolymer: More than on type Classification of Polymers 1. According to Origin: • Natural polymers: the basic constituents of any living matter, whether plant or animal, e.g. a) proteins b) polysaccharides (starch) c) polynucleic acids (DNA) • Synthetic polymers: They are produced in the laboratory by chemical reactions, e.g. • Acrylic resin and elastic impression materials • vinyl polymers which are derivatives of C2H4 2. According to Spatial Structure 1. Linear: In linear polymers: the structural units are connected to one another in linear sequence. 2. Branched: In which side branch chains are connected to the main ones. 3. Cross-linked polymers: In which the adjacent linear chains are joined one to another at various positions by covalent bonds. Linear homopolymer Branched homopolymer Cross-linked 3. According to Thermal Behavior Thermoplastic polymers *They are polymers which can be shaped by heat and after cooling they maintain their shape (i.e. they soften by heat and harden by cooling). *In thermoplastics the polymer chains are bonded to each other by secondary bonds. *They are relatively soft and their mechanical properties are sensitive to heat. *They dissolve in organic solvents. e.g. non crosslinked polymethyl methacrylate. Thermosetting polymers * They are formed into a permanent shape and set by a chemical reaction. *They can not be remelted and reformed into other shape but degrade or decompose upon being heated to high temperature. *Thus thermosets can not be fused. The polymer chain in the thermoset polymers forms network, with cross-links between them (primary covalent bonds). Preparation of polymers by a process called polymerization which is the chemical reaction by which monomer units become chemically linked and form polymer. Setting reactions I- Types of polymerization reactions: A- Condensation polymerization B- Addition polymerization 1. Condensation polymerization: Definition: reaction between two molecules to form a larger molecule, with the elimination of a smaller molecule (by-product)). Characterized by: 1- Stepwise reaction. 2- Usually consists of more than one monomer species. 3- Small molecular weight due to by – product elimination. 4- Slow reaction and short polymer chains. Examples of condensation polymerization in dentistry are: Polysulphides and Condensation Silicones : The low molecular weight paste is converted to a high molecular weight material. ***Water and lead sulfide are by-products of this reaction. 2. Addition polymerization: Characterized by: 1- Faster reaction. 2- No by - product. 3- High molecular weight. Addition polymerization results in the formation of large molecules without the formation of byproducts. No change in composition takes place. The structure of the monomer is repeated many times in the polymer, e.g. poly (ethylene), poly (acrylic acid), poly (methacrylic acid) and poly (methyl methacrylate). Stages of addition polymerization: i- Initiation. ii- Propagation. iii- Termination. a. Activation and initiation : ***Requires the presence of free radicals. A free radical is a compound with an unpaired (unshared) electron. This unpaired electron makes the radical very reactive. When a free radical (R•) encounters a double bond → it pairs with one of the electrons leaving the other member of the pair free. Dot = single electron Now the monomer is a free radical By initiator like benzoyl peroxide to release free radical. *** Initiator must be activated to release the free radicals. Methods of Activation: *Heat *Light *Chemical cpd. (dimethyl paratoluidine) → Dissociation of peroxide initiator to give free radicals Addition polymerization could be inhibited by any material that reacts with the free radical b. Propagation: Linear growth of molecules → ***Shifting of free radical to the end of the growing chain. *** ↑ Viscosity Chain reactions should continue, with the evolution of heat, until all the monomer has been changed to a polymer. And so on until R1Mn•. Where n is any integral number. c. Termination: The chain reactions can be terminated either by 1) Direct coupling or by the. 2) Exchange of a hydrogen atom from one growing chain to another Factors associated with polymerization: a. Evolution of heat as the reaction is strongly exothermic due to breakage of bonds. b. Reduction in volume on polymerization (polymerization shrinkage) c. Residual monomer Inhibition of polymerization: Any impurity in the monomer which can react with free radicals will inhibit or retard the polymerization reaction It can react either with the activated initiator or any activated nucleus, or with an activated growing chain to prevent further growth. Such inhibitors influences the length of the initiation period markedly, as well as the degree of polymerization. . Hydroquinone, Eugenol, Or large amounts of Oxygen Factors affecting properties of polymers *1**Generally the polymers are molecular solids where: • Strong primary covalent bonds does not exist between the mers along the whole length of the polymer chain (interatomic) Weak secondary Van der Waal forces exist between the chains of the polymer (intermolecular). Secondary Van der Waal forces (weak, polar bond) are responsible for; - Reduced strength, hardness and rigidity. - Higher water sorption. 2** Polymers are characterized by being amorphous and having glass transition temperature (it is the temperature at which the polymer start to be soft i.e. above which the polymer is soft and rubber like material, and below which the polymer will be very rigid Factors affecting properties of polymers 1. Molecular weight: Molecular weight of the various mers multiplied by the number of the mers = M.W of one monomer X No. of monomer units The higher the molecular weight of the polymer, → the higher the degree of polymerization 2- Degree of polymerization: defined as the total number of mers in a polymer chain. D.P.= M.W. of a polymer/ M.W. of a mer Effect on the properties; Polymers made up of large molecules are **stronger and ** more resistant to thermal and mechanical stresses than those composed of small molecules. The longer the polymer chain → the greater the number of entanglement that can be formed among the polymer chain. i.e. The more difficult to distort the polymer. ***Strength, rigidity, and glass transition temperature increase with increasing chain length. 3- Cross-linking: Adjacent linear chains are joined one to another at various positions by chemical bonds (covalent bonds). → 3-dimensional network cross-linked structure. The effect of cross-1inking: A small degree of cross-linking limits the amount of movement of the polymer chains relative to each other when the material is stressed. This * increases : - strength, hardness, rigidity, resistance to the action of solvents and - glass transition temperature. * decreases water sorption. Extensive cross-linking may lead to embrittleness of the material 4. Co-polymerization: Copolymers are polymer chains containing two or more different types of monomeric units. Co-polymerization processes enable chemists to "tailor-make" molecules of predicted properties for special applications. Co-polymers are of three different types: random, block and graft. Branched co-polymer random Graft co-polymer Linear co-polymer random Block co-polymer 5. Plasticizers: They are compounds which are added to partially neutralize the secondary bonds or intermolecular forces that normally prevent the resin molecules from slipping past one another when the material is stressed. There are mainly two types of plasticizers: a. External plasticizers: in which the plasticizer penetrates between the polymer chains. The polymer chains become further apart and the forces between them become less. b. Internal plasticizers: plasticizer of a resin can also be accomplished by copolymerization with a suitable co-monomer. In this case the plasticizer is a part of the polymer main chain. The effect of plasticizers: *They usually reduce the strength and hardness of the resin * Reduce the softening point (glass transition temperature) ***At room temperature the main difference between rigid and flexible polymers is that the former have their glass transition temperature above room temperature whereas the latter have theirs below room temperature. (the opposite action of cross-linking agent). 6. Addition of inorganic filler to the polymer forms composite structure Effect on the properties: It increases strength, hardness, and rigidity of a polymer. Physical state of polymers Dental polymers exist at room temperature either as rubbers (elastomers) or hard and amorphous (organic glasses). Rubbers (Elastomers) consist of long chain molecules that are coiled and in random thermal motion. The specific feature of a rubbery polymer is that when the material is stretched the only work done is in uncoiling the molecules. Thus such materials are easy to deform, the deformation being largely reversible. Applications in dentistry 1. Denture base materials. 2. Acrylic artificial teeth for partial and complete dentures. 3. Composite filling materials. 4. Cements (zinc polycarboxylate and glass ionomer). 5. Impression materials (Agar, Alginate and Rubbers) N Chain transfer: Process differs from the termination reactions described in that the active state is transferred from an activated radical to an inactive molecule and a new nucleus for further growth is created. An already terminated chain might be reactivated by chain might be reactivated by chain transfer, and continue to grow General Points Polymers made up of large molecules are stronger and more resistant to thermal and mechanical stresses than those composed of small molecules. Growth of polymer chains is a random process. Some chains grow faster than others and some are terminated before others. Thus, not all chains within the polymer will have the same length. Each chain will have its own molecular weight and degree of polymerization. Molecular weight of a polymer is reported as the average molecular weight because the number of repeating units may vary greatly from one molecule to another. The molecular weight distribution (i.e. the fraction of low, medium, and high molecular weight molecules in a material), has an important effect on the physical and mechanical properties as the average M.W. does. e.g. Two polymers having the same chemistry and average molecular weight may have different properties. This may be because one is formed of long large chains while the other is formed mainly of shorter chains i.e. different molecular weight distribution Properties of polymers: Polymer chains are weakly bond by secondary forces while metals have relatively strong primary (metallic) bonds. 1. The elastic moduli of polymers are much lower than metals. 2. More tendency to creep or flow. 3. Sensitive to the rate of loading (or rate of deformation). i.e. At slow rate of loading they behave in a ductile manner (more permanent deformation). At high rates of loading they respond in a brittle manner (fracture after elastic limit). 4. Sensitive to temperature. They soften as they are heated near to their glass transition temperature (below Tg the material will be rigid). 5. strength can be increased by: a. Increasing the degree of polymerization and thus increasing M.W. b. Cross-linking. c. Copolymerization. d. Addition of inorganic fillers to form composite structures. e.g. composite restorative resins. The effect of temperature on intermolecular forces increase as temperature decreases, and at a certain temperature (the glass transition temperature Tg) the intermolecular forces become so large as to inhibit uncoiling. Below the glass transition temperature the material will be rigid. Likewise if a hard polymer (organic glass) is heated (above Tg), it looses rigidity at a certain temperature above room temperature and becomes rubbery