The Structure and Properties of Polymers

advertisement

The Structure and Properties of

Polymers

By:Sawsan

D.Shubbar

V

What is a polymer?

• A long molecule made

up from lots of small

molecules called

• monomers.

All the same monomer

• Monomers all same

type (A)

• A+A+A+A

• -A-A-A-A• eg poly(ethene)

polychloroethene

PVC

Different monomers

• Monomers of two

different types A + B

• A+B+A+B

• -A-B-A-B• eg polyamides

• polyesters

Copolymers

• Copolymers are like polymer alloys.

Different mers are joined to form a mixture

in the backbone, eg. ABS.

• they can be tailored to obtain specific

properties.

Thermoplastics (80%)

• No cross links between chains.

• Can change shape.

• Can be remoulded.

Thermosets

• Cross-linking formed by covalent

bonds.

• Bonds prevent chains moving relative

to each other.

What Makes Polymers Unique?

• Really big molecules (macromolecules) like

polymers have very different properties than

small molecules. When polymer is melted,

the chains can flow past each other.

Chain entanglement: Long polymer chains

get entangled with each other.

Molecular Weight of Polymers

Unlike small molecules, polymers

are typically a mixture of differently

size molecules.

Mv Mn

Only an average molecular

Mw

weight can be defined.

#

o

f

m

o

le

cu

le

s

•

•

•

•

increasing molecular weight

Longer chains make stronger

polymers.

• There is a critical length

needed before strength

increases.

• An average No. of 100

repeating units is

necessary for HC

polymers but only 40 for

nylons.

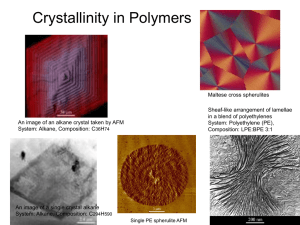

Crystalline polymers

• Crystallinty is areas in

polymer where chains

packed in a regular way.

• Both amorphous and

crystalline areas can exist

in the same polymer.

• More crystalline polymer

causes stronger and less

flexible polymer.

Melting temperature (Tm)

• The (Tm) when applied to polymers

suggests not a solid-liquid phase transition,

but a transition from a crystalline phase to a

solid amorphous phase. Crystalline melting

is only discussed with thermoplastics, as

thermosets will decompose at high

temperatures rather than melt.

Glass transition temperature (Tg)

The glass transition temperature (Tg)

describes the temperature at which

amorphous polymers undergo a second

order phase transition from a rubbery,

viscous amorphous solid (fresh spaghetti) to

a brittle, glassy amorphous solid (3 days old

Spaghetti)

Tensile strength

• The tensile strength of a material quantifies how much

stress the material will endure before failing. In general

tensile strength increases with polymer chain length.

Tensile strength

• Mechanical behavior of amorphous and semicrystalline polymers is strongly affected by Tg

• In general

• Polymers whose Tg is above the service

temperature are strong, stiff and sometimes brittle

• e.g. Polystyrene (cheap, clear plastic drink cups)

– Polymers whose Tg is below the service temperature

are weaker, less rigid, and more ductile

• Polyethylene (milk jugs)

Polymer additives

Before its conversion into plastic products,

polymer

resins

is

almost

always

compounded with various additives of

different nature, meant to improve

processing , stability, or mechanical

specifications.

Plasticizers

Are small molecules which occupy position

between polymer chains (like adding

water to mud to make it easy in molding)

1. To increase flexibility, elongation and to

reduce hardness and stiffness.

2. To lower the processing temperature

(energy saving, decomposition preventing)

Plasticizers

Plasticizer properties:

•

•

•

•

•

•

•

Low viscosity

High stable towards water and oils.

Low vapor pressure (Bpt is high).

Stable towards light and heat.

Low toxic.

Compatible.

Colorless.

Stabilizers

• Heat stabilizers (Pd soap, dibasic

phosphate).

• Antioxidants (easy to oxidize-phenols).

• UV absorbants.

• Light stabilizers: carbon black 2% = (1 to

20 years).

Fillers

Improves the attitude and lowers the cost (fiber , powder).

• Max. improvement for physical properties.

• Low water absorbance.

• Low specific gravity.

• High polymer wetting.

• Free from abrasives.

• Cheap and available.

• Odorless.

• Color compatible.

Polymer additives

• Blowing agents: physical, chemical.

• Antistatic agents: ethoxilated ammins.

• Lubricants: to allow easier processing and to

slides through dies easier {stearates}.

• Colorants: dyes or pigments.

• Reinforcing agents: (glass fiber, kevler).

• Flame retardants: (Cl/F and Br).

• Odorants

Forming of polymers

•

Polymeric materials are normally fabricated at

elevated temperatures and often by application

of high pressures.

• The technique used to form a particular polymer

depends on :

1. Whether it is thermoplastic or thermosetting.

2. The geometry and size of the final product.

Compression moldings

Both thermoplastic and thermosets can be formed by

compressing molding. Squeeze molten polymer between

hydraulic press.

Injection molding

In injection molding , polymer granules are

Compressed by a ram or a screw

Injected until molten.

Thermoplastic extrusion

Blow moldings

• Not to be confused with film blowing

( which is an extrusion-based process).

Thank you