2013_5_may_IPRM_lee_slides - University of California, Santa

advertisement

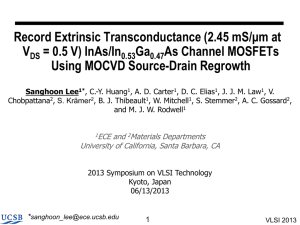

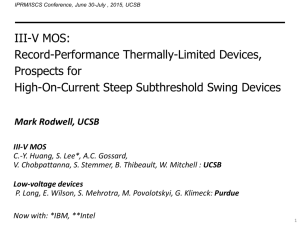

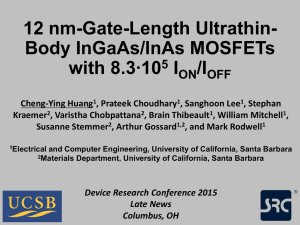

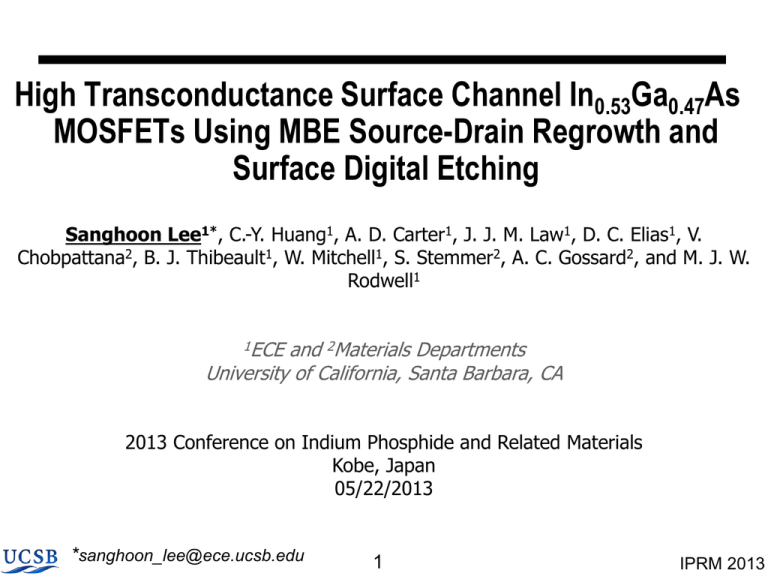

High Transconductance Surface Channel In0.53Ga0.47As MOSFETs Using MBE Source-Drain Regrowth and Surface Digital Etching Sanghoon Lee1*, C.-Y. Huang1, A. D. Carter1, J. J. M. Law1, D. C. Elias1, V. Chobpattana2, B. J. Thibeault1, W. Mitchell1, S. Stemmer2, A. C. Gossard2, and M. J. W. Rodwell1 1ECE and 2Materials Departments University of California, Santa Barbara, CA 2013 Conference on Indium Phosphide and Related Materials Kobe, Japan 05/22/2013 *sanghoon_lee@ece.ucsb.edu 1 IPRM 2013 Outline Motivation: Why III-V MOSFETs? Key Design Considerations - Device Structure : Gate-last with S/D regrowth - Damage during regrowth : surface digital etching Process Flow Measurement Results - I-V Characteristics - TLM measurement Conclusion 2 IPRM 2013 Why III-V MOSFETs in VLSI ? more transconductance per gate width more current (at a fixed Vdd )→ IC speed or reduced Vdd (at a constant Ion)→ reduced power or reduced FET widths→ reduced IC size increased transconductance from: low mass→ high injection velocities lower density of states→ less scattering higher mobility in N+ regions → lower access resistance Other advantages heterojunctions→ strong carrier confinement wide range of available materials epitaxial growth→ atomic layer control 3 IPRM 2013 Key Design Considerations Device structure: Scalability (sub 20 nm-Lg,<30 nm contact pitch) : self-aligned S/D, very low ρc 2) Carrier supply: heavily doped N+ source region3) Shallow junction: regrown S/D3) or Trench-gate Channel Design: Thinner wavefunction depth: Thin channel, less pulse doping. More injection velocity: high In-content channel4) Gate Dielectric: Thinner EOT : scaled high-k dielectric Low Dit : surface passivation5), minimized process damage6) 1) M. Wistey et al. EMC 2009; 2) A. Baraskar et al. IPRM 2010 ; 3) U. Singisetti et at. EDL 2009 ; 4) S. Lee et al. EDL 2012 (accepted); 5) A. Carter et at. APEX 2011; 6) G. Burek, et al, JVST 2011. 4 IPRM 2013 Device Structure : Gate-Last process Gate-First Fully self-aligned transistor at nm dimensions Process damage during gate metal deposition and definition Large ungated region: High pulse doing Large leakage current and increase in wavefunction depth A. Carter et at., DRC 2011 Gate-Last (substitutional-gate) Low-damage process: Thermal gate metal, No plasma process after gate dielectric deposition Rapid turn-around rapid learning. Ti/Pd/ Au S/D metal Ni/Au N+ InAs (Regrown S/D) Capping layer 10 nm InGaAs (Channel) InAlAs (Barrier) InP (Substrate) 5 IPRM 2013 Evidence of Surface Damage During Regrowth Long-channel FETs: consistently show >100 mV/dec. subthreshold swing Indicates high Dit despite good MOSCAP data. Suggests process damage. Experiment: SiO2 capping + high temp anneal + strip MOSCAP Process Finding: large degradation in MOSCAP dispersion. Confirms process damage hypothesis. o SiO Capped, 500 C anneal Control 2 1.2 1 KHz 10 KHz 100 KHz 1 MHz Capacitance (F/cm2) 1 Large dispersion Large Dit 0.8 0.6 0.4 0.2 0 -2 -1 0 1 2 -2 -1 Voltage (V) 6 0 1 Voltage (V) 2 IPRM 2013 Post-Regrowth Surface Digital Etching for Damage Removal HSQ (Regrown S/D) N+ InAs 5 nm n+ InGaAs (Capping layer) N+ InAs (Regrown S/D) Capping layer 10 nm InGaAs (Channel) 10 nm InGaAs (Channel) InAlAs (Barrier) InAlAs (Barrier) InP (Substrate) InP (Substrate) - Surface removed by digital etch process 2’ in BOE (dummy gate removal) , # cycles: 15’ UV ozone (surface oxidation) 1’ dilute HCl (native oxide removal) 13 - 15 Ȧ/cycle, ~0.16 nm RMS roughness - Etch significantly improves subthreshold swing and gm - Using this technique, we can easily thin the channel thickness. 7 IPRM 2013 Process Flow HSQ HSQ 5 nm n+ InGaAs (Capping layer) HSQ (Regrown S/D) N+ InAs 5 nm n+ InGaAs (Capping layer) (Regrown S/D) N+ InAs 5 nm n+ InGaAs (Capping layer) 10 nm InGaAs (Channel) 10 nm InGaAs (Channel) 10 nm InGaAs (Channel) InAlAs (Barrier) InAlAs (Barrier) InAlAs (Barrier) InP (Substrate) InP (Substrate) InP (Substrate) - Epitaxial layer growth - Dummy gate definition - InAs Source/Drain regrowth - Mesa isolation - InAs debris wet-etching 3 nm 3.9e12/cm2 Pulse doping 1 nm/ 4 nm Al2O3/HfO2 Ti/Pd/ Au Ni/Au N+ InAs (Regrown S/D) Capping layer N+ InAs (Regrown S/D) Capping layer S/D metal Ni/Au N+ InAs (Regrown S/D) Capping layer 10 nm InGaAs (Channel) 10 nm InGaAs (Channel) 10 nm InGaAs (Channel) InAlAs (Barrier) InAlAs (Barrier) InAlAs (Barrier) InP (Substrate) InP (Substrate) InP (Substrate) - Dummy gate removal - Capping layer digital etching - High-k deposition - Annealing - Gate metal deposition 8 - S/D metal deposition IPRM 2013 2.0 1.8 1.6 1.4 1.2 1.6 1.4 1.2 1.0 0.8 0.6 0.4 VDS = 0.5 V VDS = 0.05 V 0.2 0.0 -0.2 0.0 0.2 0.4 0.6 1.0 0.8 0.6 0.4 0.2 0.0 0.8 Current Density (mA/m) 2.0 1.8 Gm (mS/m) Current Density (mA/m) I-V Characteristics for short and long channel devices 10 1 10 0 10 -1 10 -2 10 -3 10 -4 VDS = 0.5 V VDS = 0.05 V SS ~ 120 mV at VDS=0.05 V -5 10 -0.2 0.0 0.6 VDS = 0.1 V to 0.7 V 0.5 0.2 V increment 0.4 0.4 0.3 0.3 0.2 0.2 0.1 0.1 0.0 -0.2 0.0 0.2 0.4 0.6 0.8 0.0 1.0 Current Density (mA/m) 0.6 0.5 0.4 0.6 0.8 Gate Bias (V) Gm (mS/m) Current Density (mA/m) Gate Bias (V) 0.2 10 1 10 0 10 -1 10 -2 10 -3 10 -4 10 -5 VDS = 0.1 V to 0.7 V SS ~ 95 mV at VDS=0.1V -6 10 -0.2 Gate Bias (V) 0.2 V increment 0.0 0.2 0.4 0.6 0.8 1.0 Gate Bias (V) - 1.6 mS/μm at Vds=0.5 V for a 65 nm-Lg device. - 95 mV/dec SS for a 530 nm-Lg device. 9 IPRM 2013 Comparison with a control sample (short channel) 0.2 V increment 1.0 0.8 0.6 0.4 0.2 0.0 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 1.2 1.0 1.2 VDS = 0.1 V to 0.7 V 1.0 0.2 V increment 0.8 0.8 0.6 0.6 0.4 0.4 0.2 0.2 0.0 -0.4 -0.2 0.0 0.2 0.4 0.6 0.0 0.8 Current Density (mA/m) 1.2 VGS = -0.4 V to 1.8 V Current Density (mA/m) 1.4 Gm (mS/m) Current Density (mA/m) Control : without capping layer and surface digital etching, 75 nm-Lg Gate Bias (V) Drain Bias (V) 10 1 10 0 10 -1 10 -2 10 -3 10 -4 VDS = 0.1 V to 0.7 V 0.2 V increment SS ~ 258 mV at VDS=0.1 V -5 10 -0.4 -0.2 0.2 V increment 1.0 0.8 0.6 0.4 0.2 0.0 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 Drain Bias (V) 1.6 1.8 VDS = 0.1 V to 0.7 V 1.4 1.6 0.2 V increment 1.4 1.2 1.2 1.0 1.0 0.8 0.8 0.6 0.6 0.4 0.4 0.2 0.2 0.0 -0.2 0.0 0.2 0.4 Gate Bias (V) 0.6 0.0 0.8 Current Density (mA/m) VGS = 0 V to 1.6 V Current Density (mA/m) 1.2 1.8 Gm (mS/m) Current Density (mA/m) Experimental : with surface digital etching , 75 nm-Lg 1.4 0.0 0.2 0.4 0.6 0.8 Gate Bias (V) 10 1 10 0 VDS = 0.1 V to 0.7 V 10 -1 10 -2 10 -3 10 -4 0.2 V increment SS ~ 124 mV at VDS=0.1V -5 10 -0.2 0.0 0.2 0.4 0.6 0.8 Gate Bias (V) - ~75 % increase in peak transconductance at Vds = 0.5 V - significantly better short channel characteristic with surface digital etching 10 IPRM 2013 Comparison with a control sample (long channel) 0.2 V increment 0.4 0.3 0.2 0.1 0.0 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.6 0.5 0.6 VDS = 0.1 V to 0.7 V 0.5 0.2 V increment 0.4 0.4 0.3 0.3 0.2 0.2 0.1 0.1 0.0 -0.2 0.0 0.2 0.4 0.6 0.8 0.0 1.0 Current Density (mA/m) 0.5 VGS = -0.4 V to 1.4 V Current Density (mA/m) 0.6 Gm (mS/m) Current Density (mA/m) Control : without surface digital etching, 500 nm-Lg 10 1 10 0 10 -1 10 -2 10 -3 10 -4 VDS = 0.1 V to 0.7 V 0.2 V increment SS ~ 240 mV at VDS=0.1 V -5 10 -0.2 0.0 Gate Bias (V) Drain Bias (V) 0.3 0.2 0.1 0.0 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 Drain Bias (V) 0.5 0.6 VDS = 0.1 V to 0.7 V 0.5 0.2 V increment 0.4 0.4 0.3 0.3 0.2 0.2 0.1 0.1 0.0 -0.2 0.0 0.2 0.4 0.6 0.8 0.0 1.0 Gate Bias (V) - Similar on-state characteristics (~0.4 V Vt shift) - Better short channel effect 11 Current Density (mA/m) 0.4 Current Density (mA/m) 0.2 V increment 0.6 Gm (mS/m) Current Density (mA/m) 0.5 VGS = 0 V to 1.8 V 0.4 0.6 0.8 1.0 Gate Bias (V) Experimental : with surface digital etching, 535 nm-Lg 0.6 0.2 10 1 10 0 10 -1 10 -2 10 -3 10 -4 10 -5 VDS = 0.1 V to 0.7 V 0.2 V increment SS ~ 95 mV at VDS=0.1V -6 10 -0.2 0.0 0.2 0.4 0.6 0.8 1.0 Gate Bias (V) IPRM 2013 TLM Measurement for S/D metal contact Resistance (Ohm-m) 800 Y = 3.9 + 25.1X 2 600 c = 0.15 -m 500 RSD= 64 -m 700 ~1.2 μm Ti/Pd/Au 400 50 nm n++ InAs (regrown) 300 5 nm n++ InGaAs Ti/Pd/Au 200 Gap InGaAs Channel 50 nm n++ InAs (regrown contact layer ) 100 0 Gate metal 5 nm n++ InGaAs (Capping layer ) 0 5 10 15 Gap (m) 20 25 400 nm In0.52AlAs (UID) 3 nm 3.9 Pulse S.I. InP - 0.15 ohm-μm2 Contact resistivity and 25 ohm/sq. sheet resistance. - 64 ohm-μm S/D access resistance (~5 % transconductance degradation) 12 IPRM 2013 Conclusion Using digital etching, damaged surface can be effectively removed in a nanometer precision without etch-stop. The removal of the damaged surface significantly improves both on- and off-state performance. gm = 1.6 mS/μm at Vds=0.5 V for a 65 nm-Lg device 95 mV/dec for a 530 nm-Lg device InAs regrown S/D provides very low contact resistivity of 0.15 ohm-μm2 . 13 IPRM 2013 Thanks for your attention! Questions? This research was supported by the SRC Non-classical CMOS Research Center (Task 1437.006). A portion of this work was done in the UCSB nanofabrication facility, part of NSF funded NNIN network and MRL Central Facilities supported by the MRSEC Program of the NSF under award No. MR05-20415. *sanghoon_lee@ece.ucsb.edu 14 IPRM 2013