Break-Even Analysis in Industrial Engineering

advertisement

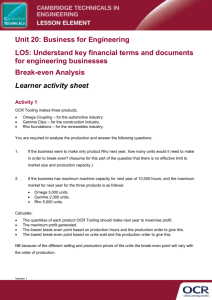

Industrial Engineering Chapter 1 Introduction to IE (Part 3) Mohamad Zairi bin Baharom Faculty of Mechanical Engineering Universiti Malaysia Pahang BMM4733_Quality Engineering Learning Objective: Determine process selection with breakeven analysis Contents: Production section with break-even analysis Break-even analysis Production Selection with Break-even Analysis A quantitative technique Useful for comparing capacity alternatives At what volume of sales and production we can expect to earn a profit The components are; Volume Cost Revenue Profit Break-even Analysis Technique for evaluating process and equipment alternatives Objective is to find the point in dollars and units at which cost equals revenue Requires estimation of fixed costs, variable costs, and revenue Break-even Analysis (cont..) Volume: level of production Cost: fixed cost and variable cost Fixed cost: remains constant regardless of the number of units produced (cost of the machine used, cost of installing the machine, cost of designing and fabricating the work holding devices, cost of the space for machine) Variable cost: vary with the volume of the units produced (cost of machine operator’s time, cost of running the machine, cost of cutting tools, cost of material used). Revenue: the price at which the item is sold Total revenue: price times volume sold Profit: difference between total revenue and total cost Break-even Analysis (cont..) – Total revenue line 900 – 800 – Cost in dollars 700 – Break-even point Total cost = Total revenue Total cost line 600 – 500 – Variable cost 400 – 300 – 200 – 100 – Fixed cost | | | | | | | | | | | – 0 100 200 300 400 500 600 700 800 900 1000 1100 | Volume (units per period) Break-even Analysis (cont..) Variables: cf = fixed cost v = volume (i.e., number of units produced and sold) cv = variable cost per unit p = price per unit Break-even Analysis (cont..) Total cost= fixed cost + total variable cost TC = cf + vcv Total revenue = volume x price TR = vp Profit= total revenue - total cost Z = TR - TC = vp - (cf + vcv) Break-even Analysis (cont..) Break even volume: TR = TC vp = cf + vcv vp - vcv = cf v(p - cv) = cf cf v= p-c v Example 1 Travis and Jeff own an adventure company called Whitewater Rafting. Due to quality and availability problems, the two entrepreneurs have decided to produce their own rubber rafts. The initial investment in plant and equipment is estimated to be $2,000. labor and material cost is approximately $5 per raft. If the rafts can be sold at a price of $10 each, what volume of demand would be necessary to break even? Example 1 (cont..) c f 2, 000 Total PROFIT revenue Total cost cv $5 per unit price $10 per unit 4,000 $ cf 2, 000 v 400 p cv 10 5 2,000 LOSS TC c f v.cv 2, 000 5v TR v. p 10v 400 Break-Even Point Units Example 1 (cont..) The intersection of these two lines is the break even point If demand is less than the break even point, the company will operate at a loss If demand exceeds the break even point, the company will be profitable The company need to sell more than 400 rafts to make a profit Example 1 (cont..) Break even analysis – useful when evaluating different degrees of automation More automated processes have higher fixed costs but lower variable costs The best process depends on the anticipated volume of demand for the product and the trade offs between fixed and variable costs Example 2 The owner of Whitewater Rafting believe demand for their product will far exceed the break even point in example 1. they are now contemplating a larger initial investment of $10,000 for more automated equipment that would reduce the variable cost of manufacture to $2 per raft. Compare the old manufacturing process in example 1 with the new process proposed here. For what volume of demand should each process be chosen? Example 2 (cont..) Point of Indifference Volume where cost of A = cost of B Rule for choosing process: Demand above point of indifference choose process with lowest variable cost Demand below point of indifference choose process with lowest fixed cost Example 2 (cont..) Process Fixed cost Variable cost A $2,000 $5 B $10,000 $2 Cost TC process A TC process B 15,000 Point of indifference TC A 2, 000 5.v 10,000 TCB 10, 000 2.v TC A TCB 2, 000 5.v 10, 000 2.v v 2667 5000 1000 2000 3000 Point of indifference = 2667 4000 units Example 2 (cont..) If demand is less than or equal to 2667 rafts, the alternative with the lowest fixed cost (process A) should be chosen If demand is greater than or equal to 2667 rafts, the alternative with the lowest variable cost (process B) is preferred Example 2 (cont..) Total cost for Each alternative Point of indifference Below Above Choose alternative with The lowest variable cost Choose alternative with The lowest fixed cost Example 3 Texloy Mfg Company must select a process for its new product, TX2, from among three different alternatives. The following cost data have been gathered; Process A Fixed cost $10,000 Variable cost $5/unit Process B Process C $20,000 $4/unit $50,000 $2/unit For what volume of demand would each process be desirable? Example 3 (cont..) Total cost for process A = $10,000 + $5v Total cost for process B = $20,000 + $4v Total cost for process C = $50,000 + $2v Point of indifference Always begin with the process that has the lowest fixed cost and compare it to the process with the next lowest fixed cost. Cost TC process B TC process A 10,000 15,000 TC process C units Example 3 (cont..) Process A versus Process B; $10,000 + $5v = $20,000 + $4v v = 10,000 units If demand is less than or equal to 10,000, we should choose the alternative with the lowest fixed cost (Process A). If demand is greater than 10,000, we should choose the alternative with the lowest variable cost (Process B) At 10,000 units we can actually choose either A or B Process B versus Process C; $20,000 + $4v = $50,000 + $2v v = 15,000 units If demand is greater than or equal to 15,000, we should choose process C If demand is less than 15,000 but greater than 10,000, we should choose process B At 15,000 units we can actually choose either B or C Example 3 (cont..) Summary Below 10,000 units, choose process A Cost TC process B TC process A TC process C Between 10,000 units and 15,000 units, choose process B Above 15,000 units, choose process C 10,000 15,000 units Exercise A firm plans to begin production of a new product. The manager must decide whether to purchase one part from a vendor at $7 each or to produce them in house. Either of two processes could be use for in house production; one would have an annual fixed cost of $160,000 and a variable cost of $5 per unit, and the other would have an annual fixed cost of $190,000 and a variable cost of $4 per unit. Determine the range of annual volume for which each of the alternatives would be best.