PRODUCTION MANAGEMENT

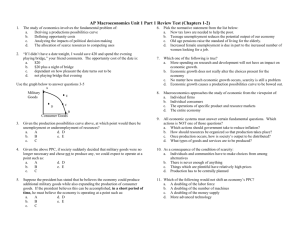

advertisement

What is Production management? Production management is the process of effectively planning and regulating the operations of that part of an enterprise which is responsible for the actual transformation of materials into finished products. 5 P`s of Production Management 1. PRODUCTS. 2. PLANT. 3. PROCESS. 4. PROGRMS. 5. PEOPLE. When this five element integrated a successful production management takes place. OBJECTIVE OF PRODUCTION MANAGEMENT 1. RIGHT QUALITY. 2. RIGHT QUANTITY. 3. PREDETERMINED TIME. 4. PRE-ESTABLISHED COST. Other objectives are : 1. Machinery and Equipment. 2. Materials. 3. Manpower. 4. Supporting Service. SCOPE & ACTIVITIES OF PM There are two types of scope & activities of PM : 1. Strategic level. (a) Design & development of new product. (b) Process design & Planning (c) Facilities location & layout planning (d) Design of material handling (e) Capacity planning 2. Operational level. (a) Production Planning (b) Production Planning (c) Inventory Control (d) Product maintenance & replacement (e) Cost Control & Cost Reduction PRODUCTION PLANNING & CONTROL (PPC) PPC is the powerful tool available to the mgmt to achieve the stated objective. Production planning starts with the analysis of data like demand & delivery schedule etc & the basis of information available and resources like machine, material & men. So, PPC is the process of directing & coordinating of firms resources towards attaining prefixed goal. FUNCTIONS OF PPC 1. Material Function 2. Machine & Equipment 3. Methods 4. Routing 5. Estimating 6. Scheduling 7. Dispatching 8. Expediting 9. Inspection 10.Evaluation TYPES OF PRODUCTION 1. BATCH PRODUCTION 2. MASS & FLOW PRODUCTION 3. PROCESS PRODUCTION 4. PROJECT PRODUCTION 5. JOBBING PRODUCTION BATCH PRODUCTION Batch production is the manufacturing of limited number of product produced at regular intervals & stocked in warehouse as finished goods. Eg. Chemical , paint & motor vehicles etc. CHARACTARISTIC OF BATCH PRODUCTION 1. Short Run. 2. Skilled labours in specific trades 3. Limited span of control 4. General purpose machine and process type layout 5. Manual material handling 6. Manufacturing cycle time affected due to queues 7. Large WIP 8. Flexible production schedule 9. Need to have PPC. JOBBING PRODUCTION Jobbing production is characterized by the manufacture of one or few number of a single product designed and manufactured strictly to customer’s specifications within the given period and within the price fixed prior to the contract. Eg: general repair shop, tailoring shops. CHARACTARITIC OF JOBBING PRODUCTION 1. Small production runs. 2. Discontinuous flow of materials. 3. Not proportionate manufacture cycle time. 4. Highly skilled labour. 5. Highly competent knowledgeable supervision. 6. Large WIP. 7. Limited function of PPC. PROJECT PRODUCTION Project production is characterized by complex sets of activities that must be performed in a particular order within the estimated expenditure. Eg: construction of Roads, Buildings etc. CHARACTARITIC OF PROJECT PRODUCTION 1. Definite beginning & definite end. 2. Non uniform requirement of resources. 3. Involvement of different agencies. 4. Fixed position layout. 5. High cost overrun. 6. Scheduling & control. MASS & FLOW PRODUCTION Mass as well as flow production are characterized by the manufacturer of several number of a std product and stocked in the warehouses as finished goods awaiting sales. The goods under mass production are manufactured either at a single operation or a series of operation on one machine. Eg: Assembly shop of automobiles, radios, electric fans. CHARACTARITIC OF MASS & FLOW PRODUCTION 1. Continuous flow of material. 2. Special purpose m/c and product type layout. 3. Mechanized material handling. 4. Low skilled labour. 5. Short manufacturing cycle time. 6. Easy supervision. 7. Limited WIP. PROCESS PRODUCTION Process production is characterized by the manufacture of single product produced and stocked in the warehouses awaiting sales. Eg: Sugar, Steel, Paper, Cement plants. CHARACTARITIC OF PROCESS PRODUCTION 1. Special purpose m/c with built in control. 2. Highly mechanized material building. 3. Virtually zero manufacturing time. 4. Low skilled labor. 5. Highly qualified supervisors. 6. Negligible WIP. 7. Limited PPC. WHAT IS PRODUCTIVITY ? Productivity is the quantitative relation between what we produce and what we use as a source of produce them. So, Productivity is the arithmetic ratio of output to the amount of input. PRODUCTIVITY = Output / Input. Productivity refers to the efficiency of the production system. PRODUCTIVITY MEASURES 1. PARTIAL PRODUCTIVITY MEASURE (PPM) PARTIAL PRODUCTIVITY= Total output / individual input. (a) Labor Productivity=Total o/p / Labor input (b) Capital Productivity = Total o/p / Material input (c) Material Productivity = Total o/p / Capital input (d) Energy Productivity = Total o/p / Energy input. 2. TOTAL PRODUCTIVITY MEASURE (TPM) = Total tangible o/p / Total tangible i/p Tangible o/p= Value of FG & Partial units produced, dividend from securities, interest, other incomes Tangible i/p = Value of ( human , material, capital, other inputs) FACTORS EFFECTING PRODUCTIVITY 1. PRODUCT. 2. PLANT &EQUIPMENT. 3. TECHNOLOGY. 4. MATERIAL & ENERGY. 5. HUMAN FACTOR. 6. WORK METHOD. 7. MANAGEMENT STYLE. PRODUCTIVITY IMPROVEMENT TECHNIQUES 1. TECHNOLOGY BASED 2. EMPLOYEE BASED.’ 3. MATERIAL BASED. 4. PROCESS BASED. 5. PRODUCT BASED. 6. MANAGEMENT BASED.