Non Destructive Evaluation-Prof. Francesco Simonetti ()

advertisement

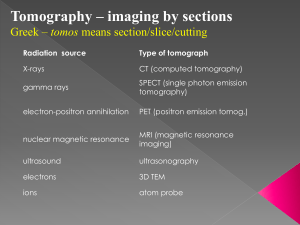

The Ultrasonic Imaging Laboratory at UC Francesco Simonetti Ultrasonic Imaging Laboratory School of Aerospace Systems University of Cincinnati http://www.ase.uc.edu/USIL Email: f.simonetti@uc.edu, Tel.: (513) 556-3532 Francesco Simonetti Sep. 1994 - Oct. 1999 MEng in Aeronautical Engineering Univ. of Palermo, Italy Feb. 2000 – Jan. 2001 Military service Italian Navy Apr. 2001 – Jan. 2004 PhD Mechanical Engineering Imperial College London Research Associate Imperial College London Jan. 2004 – July 2005 Aug. 2005 – July 2010 Research Fellow Royal Academy of Engineering June 2006 – Current Faculty Affiliate Los Alamos National Laboratory Feb. 2007 – Mar. 2011 Assistant Professor Imperial College London April 2011 – Current Associate Professor University of Cincinnati The Laboratory Over 1200 Sqft, the Ultrasonic Imaging Laboratory (USIL) was established in 2011 under the Ohio Research Scholar Program. USIL is at the forefront of modern imaging technology with the mission to develop the next-generation sensing technology for applications in industry and medicine. Key focus areas include: Integrated sensing technology for life-cycle operation and management High-sensitivity and specificity damage detection methods Earlier diagnosis of diseases Core facilities In addition to standard equipment for basic and applied research over the entire ultrasonic regime, the Lab has state-of-the-art instrumentation including: • Ultrasonic Microscope for testing up to 300MHz • 128-channel programmable controller to drive array probes up to 20MHz • Microwave Vector Network Analyser up to 64GHz • High resolution Infrared Camera • Laser Doppler Interferometer 24MHz bandwidth • Computer workstation with 32 cores and 256GB RAM Research areas covered Ultrasonic imaging • Conventional beamforming • Tomography • Super-resolution imaging • Augmented reality Guided waves • Ultrasonic • Microwave Material Characterization • Mechanical properties • Electromagnetic properties Application areas covered NDE (Aerospace, Nuclear, Power, Oil & Gas) • CMC materials • Austenitic steel castings • Steel manufacturing Structural Health Monitoring (Aerospace, Oil & Gas) • Fuselage skin • Corrosion in pipelines Medical diagnostics • Breast cancer detection • Needle biopsy Geophysics (Los Alamos National Lab) • CO2 sequestration monitoring • Oil reservoir imaging People Over the past two years the Lab has supported five graduate students, two undergraduates and one research associate The current team members Industrial support Total industrial support is $1.2 M over three years, with the main sponsors being GE Aviation • NDE methods for CMC materials • Vibration analysis of damping coatings Electric Power Research Institute • Ultrasonic inspection of austenitic steel Research focuses on solving real problems The research activity ranges from the underpinning mathematical and physical aspects of advanced sensing technology to the design and testing of prototype systems. Theoretical modeling, numerical simulations, and experiments are central to our work. Commercialization An example: Corrosion depth monitoring It is estimated that the direct cost of corrosion to industrialized countries represents a significant proportion of the gross domestic product (GDP), with some analysts suggesting that the cost of corrosion to the US alone is as high as 3.1% of its GDP • Depth monitoring is currently done with hand-held probes • Hand-held probes require direct access to the corroded area • Often access is limited due to physical obstacles or remote location • Guided ultrasonic waves enable remote inspections • Our solution is to combine guided wave technology with advanced tomography algorithms Pipe testing configuration Transmit and receive ring arrays of guided ultrasonic wave transucers are used to inspect the full section of pipe between the two rings. The transducers use a novel design for superior thermal stability. First prototype Current prototype Advanced imaging algorithms We have translated our experience in breast ultrasound tomography to corrosion monitoring. Advanced Ultrasonics Conventional Ultrasound X-ray CT m/s 20mm 1560 20mm 1540 1520 1500 1480 1460 Simonetti et al. App. Phys. Lett. 95 (2009) Simonetti et al. Med Phys. 36 (2009) 20mm Advanced modelling algorithms Developed new physical models to describe the interaction of ultrasonic guided signals with complex shape defects in complex structures. These forward models are integral parts of our imaging algorithms Reconstructed wall thickness loss map With tomography we provide point-by-point maps of wall thickness loss. The measurement accuracy that we obtain is better than 1% of the wall thickness 50 10 45 9 40 8 35 7 30 6 25 5 20 4 15 3 10 2 5 1 0 -30 -20 -10 0 X-axis [cm] 10 20 30 0 % of wall thickness Y-axis [cm] Maximum Depth 0.76 mm Innovation We are introducing a shift of paradigm in the field of NDE technology by integrating advanced computing with ultrasonic hardware for the first time. 1. Transducers: New non-contact transducer design with higher sensitivity and stability Transducer System Control System Pre-processing System 2. Control System: Custom made electronics for the new transducer design Inversion System 3. Software: Imaging algorithm more advanced than those used in x-ray CT. Operator Terminal Cincinnati NDE, Ltd. A start-up form the University of Cincinnati that is targeting commercial applications in the oil and gas, nuclear, and aerospace industries. Ceramic Matrix Composites (CMC) CMC materials promise to improve the efficiency and reduce the emission of jet engines. Enabling aspects of CMC technology are • Allows higher turbine temperature • Improves efficiency of thermodynamic cycle • Significantly lighter than superalloys • Reduces or eliminates the need for coolant NDE of CMC at UC CMC materials are very different from other aerospace materials and therefore require new NDE methods. At UC we work closely with GE Aviation to develop the next generation NDE technology for CMCs and the different aspects of the life cycle of CMC components Quality Control CMC Substrate Coatings for CMC Damage progression monitoring Room temperature High Temperature In-service Inspections Module level Piece part level Conclusions • The research scholar award has been instrumental to the creation of USIL • USIL is helping local aerospace industries developing innovative materials for jet engines • Cincinnati NDE, ltd. has been established as the first spin off from the research at USIL • USIL is training the next generation of NDE engineers

![paper_ed18_19[^]](http://s3.studylib.net/store/data/005893335_1-df041ccf2a0aa177c757e722ab2941b1-300x300.png)