High Temperature (>500o C) Ultrasonic Transducers: An

advertisement

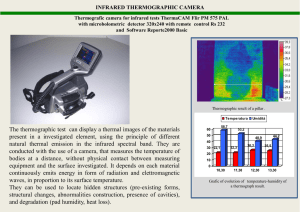

D. Parks, K. Sinding, S. Zhang and B. Tittmann Penn State University, University Park, PA 16802 [1] Motivation [2] Objective [3] Work in Progress [4] Results [5] Conclusions Motivation Ultrasonic techniques have been widely applied for non- destructive evaluation (NDE) of material properties and structural integrity. The ability to apply typical ultrasonic techniques in high temperature environments is desired for the monitoring of process variables, such as viscosity of melts evaluation of structural/material integrity in harsh environments, e.g., turbine blades, combustion engines and nuclear reactors. Aircraft engine turbine and fan disk cracks have led to disk burst and catastrophic engine failures: Problem Statement United Airlines 232, Sioux City, Iowa, (1989) – 111 fatalities Delta Air Lines 1288, Pensacola, Florida, (1996) – 2 fatalities Air Florida Airlines 2198 – takeoff aborted Part of the DC-10's fuselage after the crash. Damaged Engine of N927DA What are the Applications? Characterization of flaws is an important goal of ultrasonic NDE in aircraft structural health monitoring to achieve retirement for cause. Aluminum wings/fuselage Composite components Turbines Steam pressure pipes/vessels Aircraft Disc brakes Application: develop in-situ monitoring techniques for a nuclear reactor environment Core Research reactors: • Material specimens • LE fuel specimens Commercial reactors: • critical structures 6 6 Fukushima Daiichi, Japan 7 Background High temperature piezoelectric materials have been surveyed previously. For example, the commercial piezoelectric material PZT possesses a Curie temperature of about 350o C but has a maximum recommended operation temperature of 150-250o C. As a result, buffer rods/ultrasonic guided waves have been utilized to keep the piezoelectric materials out of the high temperature region for extended periods of time. Limitations Limitations of a guided wave system include, depending on the required waveguide geometry, the following limitations: Dispersive behavior limiting bandwidth Sensors size Cumulative attenuation losses over the waveguide propagation length Losses due to material discontinuities along the ultrasonic propagation path New Materials The limitations imposed by this methodology have been one of many driving forces that are leading to the development of new piezoelectric materials with operational temperatures exceeding 350o C. The relatively new high temperature capable materials include high Curie temperature ferroelectric materials and non-ferroelectric single crystals. Additionally, depending on the intended operating frequency, electrical resistivity becomes problematic for high temperatures and low frequency operating conditions Candidate Piezoelectric Materials High Curie Temperature Few stable phase transitions High electromechanical coupling 11 No problematic atomic species Reactor waste requirements Kaz Show that AlN performs in γ up to 18.7 MGy AlN The group III-V material Aluminum Nitride (AlN) belongs to the Wurtzite structure and point group 6mm and is not ferroelectric. No phase transitions exist aside from the melting point at 2800o C resistivity of high quality crystalline samples is on the order of 10 MΩcm at 200o C. The dielectric constant has been measured to be 8.5 and the piezoelectric strain constant has been estimated from thin films to be roughly 5 pC/N. Transducer Design Reactor waste requires relatively short half life isotopes (Al 6061 primary material) Aluminum foil coupling is used after heat treatment for a Brazed contact Waveguide Al 6061 for in-situ characterization Develop radiation tolerant BNC cable Fused-Quartz insulation Aluminum conduit sleeve/inner conductor 50ft Low Loss RG 213 U Carbon-Carbon backing Monolithic bulk z-cut single crystal AlN centered at 13.4 MHz 13 Purpose: Understand Sensor Test Setup Behavior Does radiation reduce piezoelectric effect tending towards an isotropic state? Is there increase dielectric loss due to defect generation and ionization Is there mechanical failure due to transducer design? Measurements Impedance (tanδ) Pulse-echo A-Scan through aluminum 6061 waveguide In-Situ Test Time : 3 Months Fast Neutron: 1.85x10^18 n/cm^2 Thermal Neutron: 5.8x10^18 n/cm^2 Gamma:26.8 MGy 14 Results Pulse-echo amplitude measured in-situ Reactor-on status measured by loss in signal amplitude Pulse-echo amplitude stable during off-state Amplitude relatively stable 15% deviation Fluctuations need to be isolated from changes in transducer mechanics 15 Lithium Niobate Ferroelectric material with a Curie temperature in excess of 1000° C depending on the stoichiometry . 3m crystal symmetry with the corundum structure. The 36° rotated Y-cut is quite sensitive in the longitudinal mode of vibration with a coupling coefficient of 0.48. known to lose oxygen at elevated temperatures, particularly at low oxygen partial pressure. decomposes at 600° C even in oxygen at atmospheric pressure. oxygen loss is an activated process so for 170 hours before observing their decomposition. YCOB Oxyborate crystals with general formula ReCa4O(BO3)3 (Re = rare earth element, abbreviated as ReCOB) used for nonlinear optic applications. no phase transitions occur prior to their melting points, those being on the order of 1400-1500° C. ultrahigh electrical resistivity at elevated temperatures. For example, YCa4O(BO3)3 (YCOB) possesses a resistivity of 2×108 Ωcm at 800° . The dielectric permittivity, piezoelectric strain constant, and electromechanical coupling factor of the (XYlw -15° /45°) cut were found to be on the order of 11, 6.5 pC/N, and 0.12, respectively, with little variation in the range of room temperature to 950o C Test Fixture for High T Normalized echo amplitude while at 550oC continuously for 60 hours in an open tube furnace Thermal Ratcheting Experiments Pulse-echo Waveforms for YCOB Sol-gel Spray-on Fabrication of BiTi transducers Fabrication method in a nut shell: Powders of ferroelectric materials are added to aqueous solution of mixed oxide precursors. Powders increase viscosity such that sol-gel can be sprayed with an air gun onto surface. Substrate is sprayed, then pyrolyzed. Repeated until desired thickness is achieved. Substrates can be metallic. Sinter, followed by electroding and poling. Sintering Typical sintering methods have proved to be destructive and difficult to handle for the sol-gel deposition method, Induction sintering has proved most effective Microwave sintering Blow torch sintering Corona Poling Corona Poling Poling method which does not require electrodes Metallic substrate is grounded and heated (150200o C), metallic needles are brought within proximity of sample surface High voltage ( ~10 kV) applied to needles, resulting electric field aligns electric domains within ferroelectric material Comb Transducer Fabrication directly on Pipe Laser ablation has been effective at creating an accurate electrode pattern for launching guided waves in pipes Bi4Ti3O12 High Temperature Response Amplitude remained relatively constant until 625 oC… followed by sharp decline. Ultrasonic response was lost after 1000 oC Bi4Ti3O12-LiNbO3 Pk-Pk Amplitude (V) 2 1.5 1 0.5 0 0 100 200 300 400 500 600 Temperature (C) 700 800 900 1000 OBSERVATIONS the long-term in-situ testing indicates that all four materials are suitable for operation at 550° C for at least 55 hours. carbon-carbon backing material is a limiting component. A solution based on a porous Al backing was found but thorough testing on this backing remains to be completed. This backing material is easily created by compressing Al foil at 550° C under 150 psi for 5 hours. Fixture Details Capacitance and Attenuation OBSERVATION The YCOB crystal exhibited a much less pronounced change in dielectric properties after heat treatment. It is expected that YCOB is more stable at high temperatures than LiNbO3 which is known to deplete its oxygen particularly at low oxygen partial pressure. YCOB, AlN and LiNbO3 exhibit stability in ultrasonic performance through the heat treatment of 950° C for 24 hours and 1000° C for 48 hours. Any variations observed were less than the experimental error. Summary High temperature piezoelectric crystals, including YCa4O(BO3)3, LiNbO3 and AlN, have been studied for use in ultrasonic transducers under continuous operation for 55 hours at 550° C. Additionally, thermal ratcheting tests were performed on the transducers by subjecting the crystals to heat treatments followed by ultrasonic performance testing at room temperature and 500° C. .The changes due to the heat treatments where less than the statistical spread obtained in repeated experiments and thus considered negligible. Finally, in-situ measurements up to 950° C, of the pulse echo response of YCa4O(BO3)3 were performed for the first time, showing stable characteristics up to these high temperature. Sol-gel Bi4Ti3O12-LiNbO3 gave good performance to almost 1000 °C CONCLUSION At atmospheric oxygen partial pressures, 48 hours of exposure to 950° C or 24 hours exposure to 1000° C had no significant effect on the efficiency of ultrasonic transduction of LiNbO3, YCa4O(BO3)3 and AlN. The oxidation of AlN, known to occur at these temperatures, had no significant effect on the ultrasonic transduction efficiency, but the difficulty to achieve high quality AlN single crystals limit their applications greatly. YCOB crystal was found to be capable of efficient ultrasonic transduction to about 1000° C. OUTLOOCK: From Navier’s equation, the temperature dependence of guided wave propagation depends on the material properties. Lame G u G u 2 u 2 t 2 34 Theoretical Dispersion Curves Effect of thermal expansion (cross-section) CTE ≈ 6 μ/K in Zircaloy 295K (70K) vs. 700K (800F) Δthickness = 0.015 mm Δwidth = 0.05 mm Negligible at 150 kHz 35 Theoretical Dispersion Curves Zircaloy bar specimen: λshear=19.7 mm @ 150 KHz Bar width = 20.625 mm Cannot use Rayleigh-Lamb equations for bar! Solve via SAFE technique 36 2D Semi-Analytical Finite Element (SAFE) Define analytical solution in the wave propagation direction Orthogonal function Discretize cross-section; Boundary conditions Eigenvalues of system = wavenumbers Wavenumbers → dispersion curves Cp k Cg k 37 Group Velocity (SAFE) 38 Group Velocity vs. Temperature (150kHz) 39 Thank you for your attention Any Questions?

![Jiye Jin-2014[1].3.17](http://s2.studylib.net/store/data/005485437_1-38483f116d2f44a767f9ba4fa894c894-300x300.png)