Initial Performance History - O&M Lessons Learned

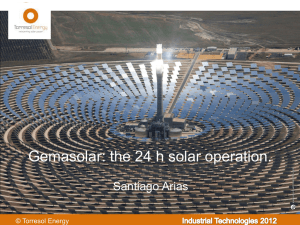

advertisement

Initial Performance History - O&M Lessons Learned Kuno Schallenberg Kuno.Schallenberg@de.lahmeyer.com +49 6101 55 1886 26 August 2013 Lahmeyer International GmbH Engineering and Consulting Services Energy Division; Business Unit Renewables and Economics Lahmeyer LahmeyerInternational International2013 2013 Solar Tower Technology Brief facts on the current status: • 3 operational projects considered commercial: – PS-10 (10 MW) – PS-20 (20 MW), and – Gemasolar (20 MW) • Large commercial projects under construction (e.g. Ivanpah) • Some pilot and demonstration experiences around the world (e.g. Solar One, Solar Two, Themis, etc.) Lahmeyer International 2013 2 Tower Project Focus: Gemasolar (Spain) Source: Torresol Lahmeyer International 2013 3 Gemasolar: Key Data Source: Torresol Lahmeyer International 2013 4 Gemasolar: Layout Decoupled System Source: Torresol Lahmeyer International 2013 5 Gemasolar: Plant behaviour (full summer week) Meinel DNI (W/m²) Actual DNI (W/m²) Heliostats focusing (u) Receiver Power (MWt) Storage Level (%) Gas use (kg/s) Net Output (MWe) Lahmeyer International 2013 Source: Torresol 6 Gemasolar: Operation - Preliminary Results • Plant is still on ramp-up period (2nd operational year) • Performance exceeds expectations on clear sky days but is lower than expected on cloudy days • Plant can operate continuously 24 hours/day (mainly summer) • Fine control of solar field and receiver temperature achieved • Cleanness factor of the solar field exceeds 95% • Storage tanks loose around 1°C/day in average • Water consumption per year rounds 400,000 m³ Lahmeyer International 2013 7 Gemasolar: Operation Event – Frozen Receiver • Event: Frozen salts on receiver tubes • Cause: operation exceeding boundary conditions (high winds) • Solution: gradual heating of the tubes using the solar field • Result: salts were melted and tubes freed • Consecuences: no mechanical or structural damages to the receiver Source: Torresol Lahmeyer International 2013 8 Gemasolar: Maintenance Lahmeyer International 2013 Source: Torresol 9 Gemasolar: Maintenance – Key Facts • Typical maintenance activities: preventive, predictive and corrective • Major emphasis on predictive maintenance, especially on non-conventional equipment (e.g. receiver, salt pumps, etc.) • Annual plant inspection (scheduled corrective maintenance) with a duration of 3-4 weeks • Turbine has shown no signs of degradation, performing substantially better than in other CSP plants • No perceived degradation on Receiver • No special maintenance activities on salt system (no corrosion noted) • Exceptions: valves (salt system) and kettle Lahmeyer International 2013 10 Gemasolar: O&M Personnel • Operation (on site): – Around 20 employees which include supervisors, EHS, process engineers and operators, divided into 5 shifts • Maintenance: – Around 30 employees which include supervisors, electromechanical technicians, chemical engineer and cleaning crews Lahmeyer International 2013 11 Gemasolar: O&M Costs 15% 8% Owner's Costs EHS Costs General Costs Maintenance Costs 29% 46% Operation Costs 2% Lahmeyer International 2013 12 Trough Technology Brief facts on the current status: • Around 3 GW installed worldwide • Large commercial projects still announced • Almost 30 years of operational track record (SEGS I built on 1984) • Relatively mature O&M experience Lahmeyer International 2013 13 Trough Project Focus: Typical 50 MW installation with TES (Spain) Lahmeyer International 2013 Source: Torresol 14 Trough Case Study: Key Data Lahmeyer International 2013 Source: Torresol 15 Trough Case Study: Typical Plant Layout Source: Torresol Lahmeyer International 2013 16 Trough Case Study: Plant behaviour (clear and cloudy days) Stored Energy Lahmeyer International 2013 Gas Heater Turbine Output Source: Torresol 17 Trough Case Study: O&M Results - Spain • Performance results are not similar/homogeneous within the plants installed recently (last 5 years) in Spain • Some plants register 15 to 20% higher annual performance compared to expected values • Experience from SEGS plants allowed optimization of O&M e.g. high performance, effective maintenance (predictive) and cost reduction • Major O&M incidents relate to HTF leakages (e.g. ball joints, flexible hoses), HTF pumps failure, HTF filtration into water/steam cycle, broken absorber tubes • There are no major incidents with the operation of the TES reported Lahmeyer International 2013 18 Conclusions & Lessons learned • Operation with molten salt systems as HTF is more delicate on changing weather conditions (e.g. cloud passages) • Decoupled systems with TES allow reduction and/or elimination of weather disturbances on the solar field (e.g. cloud passages), allowing a better operation of the turbine • No special events detected on the operation of molten salt storage systems • O&M cost reductions on existing plants are very unlikely without losing plant performance • Increasing project size or multiproject development might be the only way to reduce O&M costs • CSP integration to existing thermal power plants represent a significant reduction on O&M costs for the solar part (e.g. almost no additional labor) Lahmeyer International 2013 19 Thank you for your Attention Questions? Lahmeyer LahmeyerInternational International2013 2013 20