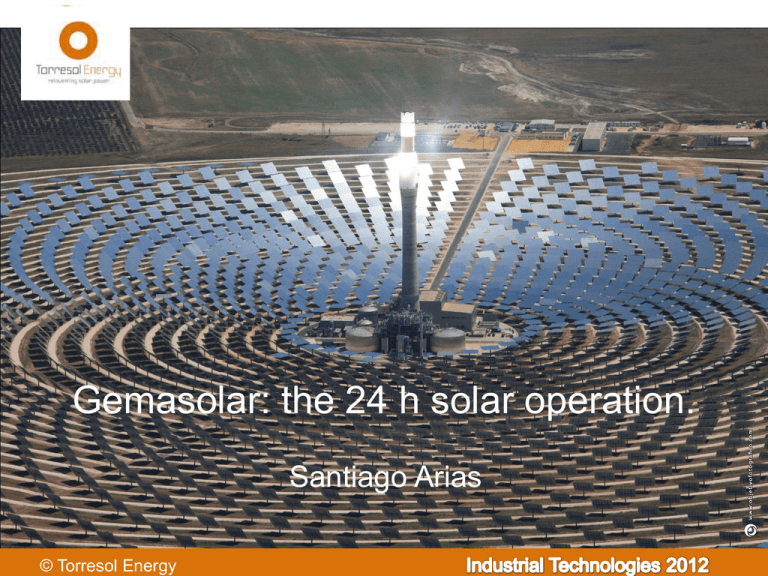

Gemasolar: the solar plant producing 24 h/day

advertisement

Gemasolar: the 24 h solar operation. Santiago Arias © Torresol Energy A Strong Alliance 60% • Engineering, consulting, and systems integration company. Founded in 1956. • Very active in Solar Energy since 2000. – Technology developer: SENERtrough collector system, Sensol software, heliostats, heliostat axis drive mechanisms, molten salt technology (as storage system and as heat transfer fluid) central tower receiver… amongst many other innovations. – PSA Tower Prototype. – Turn Key Projects: Andasol 1 & 2, in Granada; Extresol 1, 2 & 3, in Badajoz; one plant in La Garrovilla… (22 CSP plants) © Torresol Energy 40% • 100% “Mubadala Development Company” stockholding. • Mubadala Development Company” belongs to the Abu Dhabi Emirate. • Goal: development and commercialization of innovative technologies in renewable, alternative and sustainable energies. Already Producing Results © Torresol Energy Sener Solar Technology • Parabolic Trough Plants • Central Tower Solar Plants • The Thermal Storage System © Torresol Energy Senertrough Solar Collector Low manufacturing cost Low assembly cost High repeatability during manufacturing and assembly of the SCEs High performance Good durability and maintenance costs Installation (1 loop=576 m of trough): 156x3 loops in Extresol 1,2&3 (270Km) 152x2 loops in Manchasol 1&2 156x2 loops in Valle 1&2 156x2 loops in Termosol 1&2 120x2 loops in ASTE 1&2 96 loops in Soluz Guzman 230x2 in USA (FLP) 124 loops in Orellana 168 loops in Africana 105 loops in Villena 156 loops in Casablanca 2X 320 loops in Lanco 1 &2 2041 Km of trough, 4.5 M arms © Torresol Energy CENTRAL TOWER PLANTS with MOLTEN SALT STORAGE © Torresol Energy Gemasolar Plant Basic Plant Description © Torresol Energy M. Salt Central Tower Advantages • High thermal storage capacity. – Due to the storage system, the turbine operation is not immediately affected by a cloud or a sudden high speed wind. A cloud will affect the production 6-15 hours later. – The turbine would not stop every night. Longer expected life. – The turbine power is manageable. We may choose reduce the output during the night, at valley time, to reach 24 h of continuous operation at lower rate. – We maximize the asset utilization. In case of GS will are expecting to produce 6400 h/year, maximizing the profitability • Lower operational costs – No mobile piping system. No swivel joints. – All fluids concentrated in an small area. Lower thermal loses and maintenance costs. Self draining piping. – The same fluid is used for heat transfer and storage. Less thermal interexchange • Highest cycle efficiency – The molten salts reach highest temperatures maximizing thermodynamic efficiency. © Torresol Energy GEMASOLAR IN FIGURES • First CSP plant in the world operating 24 h/day. © Torresol Energy Local Content The plant is composed of : 80 km of internal roads (local) 5 Km or paved roads (local) 2650 Heliostat Foundations (local) 2650 Heliostat columns and metal structure (local) 2650 Heliostat assembly (local) 300,000 m2 of flat silvered glass (local) 1 Reinforced concrete tower (local) Carbon steel and SS piping (local) Carbon and SS tanks and vessels (local) Hundreds of Km of cooper wire (local) Electrical installation (local) 5500 Standard Electrical motors (local) Etc. In the case of Gemasolar (Spain): 99% of the added value was European 90% of the added value was local (Spanish) 65% of the added value was local (Andalusia region) º © Torresol Energy Investment Economical activity. Jobs. Long term free and clean energy Actual Performance © Torresol Energy Production meets expected values • Producing electricity since May. • Exceeded nominal values Thermal Power :More than120MWt Electrical power : 19,9 MWe • Improving daily production: Fast learning curve for an innovative project. • Excellent production predictions © Torresol Energy Production meets expected values © Torresol Energy What about the future? • We, and most of the analysts, consider that the technology of Central Tower plants with Molten Salts has higher opportunities to achieve the grid parity in a shorter period of time due to: • Larger future cost reduction. • Size to be increased. • New equipment yet to be developed. • Affordable construction materials. • High percentage of local content. Concrete, structural steel ,flat glass… • Next Steps: • 240 MWt receiver (5000 heliostats) • Variable electrical power depending on Market requirements © Torresol Energy © Torresol Energy