Remote Control of an ATV using a myRIO and iPad

advertisement

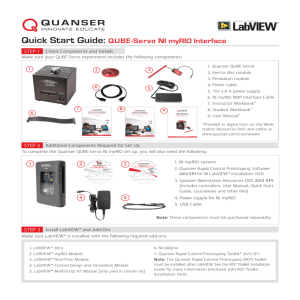

Remote Control of an ATV Team members: Bryce Aberg Eduardo Barcellos Faculty: Stacy Wilson Ron Rizzo Background Information • • • Originally developed by WKU’s Engineering Manufacturing Commercialization Center (EMCC) Used as a mobile platform to detect subsurface voids Applications include: Sinkhole detection, tunnel/bunker detection Project Objectives • • Remote control of the steering, throttle, choke, brakes, start/stop of an ATV Communicate through WiFi to a myRIO that will control these systems by using shared variables. Block Diagram Haydon Motor Controller (Throttle, Choke) • • • • Step-motors need a driver Clipper has internal and external control Stepper-motors can be controlled by sending a clock signal (10Hz – 2KHz) from the myRIO to the Clipper Inputs on the Clipper for direction, clock, motor enable Sabertooth 2x25 (Steering) • • • • Linak actuator controls steering, requires 20A Sabertooth 2x25 motor controller can control up to two 25A motors. Two control options: Serial and analog on S1 and S2 For analog: <2.5V on S1: Backwards =2.5V on S1: No movement >2.5V on S1: Forwards • • • Relays (Brakes, start/stop) • • • Zettler relays used to control solenoid actuator Solenoid is connected to thick wire to control brakes Another relay controls the engines ignition myRIO Pinout Current Front Panel Shared Variables • • • Variables that can be shared between programs or across a network Several types, this project will be using network-published shared variables Can be changed using an app on the iPad (Data Dashboard) Current Status • • • • We have almost all the basic functions complete All motors and relays can be controlled through LabView No wireless connectivity Wiring system is a mess Future Goals • • • • Update code to use event handling Implement shared variables in LabView Design board that will connect to myRIO to replace the stock board Streamline the wiring on the ATV