Enu-LIFT Sheet-Follower

advertisement

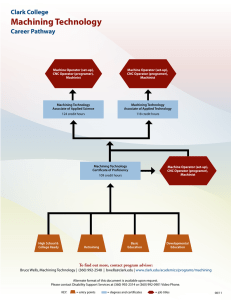

Enu-LIFT Sheet-Follower A Product of Enutron Automation Effective, simple solution for handling large parts Reduces a two-man operation to one Simple add-on to any hydraulic press brake Ideal solution for productivity and safety What is the Enu-LIFT ? Specifications Weight Capacity: 400 lbs (181.5 kg) Heavy-duty construction Vertical Adjustment: +/- 60 mm Horizontal Adjustment: +/- 60 mm Mechanical Accuracy: +/- 0.2° Extendable arm for longer parts Perfect synchronization with bending speed Follows material during bending phase in perfect synchronization Extendable arm on Enu-LIFT allows flexibility for handling larger parts How does the Enu-LIFT work ? Fixed Mounting Performed during OEM construction of press brakes • •Sheet-follower is permanently attached to BED •Ability to slide from side to side on precision linear guide •When not in use, operator can push aside Transportable Ability to move from one machine to another • • Simple plug and play • Quick detach and re-attach Precision dowel pins to mate system to press brake BED • Most effective, saving on cost of labor time as is involved with fixed system • 2-Man Operation VS. Enu-LIFT Inconsistent bend angle throughout length of material Provides proper/uniform support for consistent bend Operator + Enu-LIFT = Effi¢ien¢y Due to difference of individual operator handling Lack of proper surface contact w/ material Financial burden: Two operators performing the same job? Benefits Option Stand-Alone CNC Simple to operate! Designed for press brakes that cannot currently control sheet-following system • • Stand-alone system Simply enter material information and tooling • • CNC automatically calculates point of following • Linear scale monitors live movement of ram Increased productivity Safer operation Professional results Results Click HERE for the Enu-LIFT Experience!