Titel (Verdana 32 pt)

advertisement

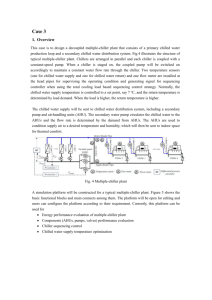

Exportinitiative Energieeffizienz ENERGY MANAGEMENT AND MONITORING FOR BUILDING IN VIETNAM Reported by: Phạm Huy Phong Deputy Director of the Energy Conservation Center HCMC www.efficiency-from-germany.info January, 2013 Contents The relevant legal documents of building sector Current energy use and potential energy savings of types of buildings Introduction to energy management system Typical case – efficient energy management system model (Legend Hotel and Television building) Decree No.102/2003/ND-CP dated September 03, 2003 of the Government on thrifty and efficient use of energy, specifies activities of thrifty and efficient use of energy in industry, in large buildings, in transportation, in daily activities and for equipment using energy. Circular No.40/2005/BXD issued energy regulations in construction. Law No.50/2010/QH12 on economical and efficient use of energy passed by the National Assembly 12 on 28/6/2010, with effect from 1/1/2011: building, authority, institution using State budget and consuming more than 500 tons of oil equivalent in one year is significant energy facility. (Article 32); Decree No. 21/2011/ND-CP of March 29, 2011, detailing the law on economical and efficient use of energy and measures for its implementation. Decree No. 73/2011/ND-CP of August 24, 2011, defining handling of administrative violations on economical and efficient use of energy. Circular No. 39/2011/TT-BCT of October 28, 2011, providing for training, grant of certificates of energy management and energy auditors. Circular No. 09/2012/TT-BCT of April 20, 2012, specifies the planning, reporting on the implementation plan on economical and efficient use of 3 energy; implementation on energy audit (process and procedures) (Source: ECC-HCMC) Biểu đồ tỉ lệ % các thiết bị tiêu thụ điện 75.9% 11.5% Air conditioning Máy lạnh 3.0% 9.5% Biểu đồ tỉ lệ tiêu thụ năng lượng Lighting Đèn chiếu sáng Office equipment (computers, printers, copiers, Thiết bị văn phòng (máy tính, in, photo, quạt,…) fans,…) 58% Thang máy & máy bơm nước 24% Elevators and water pumps Offices 18% Hệ thốngsystem chiếu sáng Lighting Air-conditioning Hệ thống ĐHKKsystem Other equipment using energy Các thiết bị tiêu thụ điện khác Commercial centers Biểu đồ tỷ lệ sử dụng năng lượng trong ngày Elevator Hệ thống thang system máy Hot water Hệ thống máy 4.95% system nước nóng 4.41% Hệ thống chiếu Lighting system sáng 9.11% HệOther thốngsystem khác 6.70% Air-conditioning Hệ thống ĐHKK system 74.83% Hotels POTENTIAL ENERGY SAVINGS – OFFICES No. % ENERGY SAVINGS SOLUTION 1 Promote awareness energy management of user, establish 2 Use air conditioning with high performance 3 Improve lighting system 3 - 5% 4 Reduce heat penetration (adjust fresh air flow, close door, improve envelop of building) 2-4% 5 Maintain air-conditioning equipment, lights 2-3% 5 - 10 % 10 - 15 % (Source: ECC-HCMC) POTENTIAL ENERGY SAVINGS – HOTELS, COMMERCIAL CENTERS No. SOLUTION % ENERGY SAVINGS 1 Improve lighting system 2-3% 2 Improve air conditioning system 3 Operate and maintain air conditioning, lighting system, … reasonably 3-5% 4 Apply new technology: cold storage tank system, solar hot water system / heat pump. 3-5% 5 Improve envelope of building 1-2% 6 Establish energy management system 1-2% 5 - 10 % (Source: ECC-HCMC) What is energy management system? A system includes: Scope: Resources – financial resources, human resource and technology Procedures/Regulations, programs in order to manage, implement activities. Areas related to energy consumption in company Purpose: Provide methods, programs clearly to implement energy savings in order to achieve planned objectives. Increase the effectiveness of other management system Maintain effective energy savings Attract the participation of personnel Have objectives to pursue 7 Continual improveme nt Cost Year No energy management Không có hệ thống QLNL system With energy management Có hệ thống QLNL system 8 PROCESS FOR ESTABLISHING ENERGY MANAGEMENT SYSTEM Current assessmen t • • • • • • Energy policy Organizational structure Motivation Measurement/Monitoring Communication –Training Investment of energy Design • • • • Establish energy team Train to enhance awareness Define energy policy Design documentation of energy management system Deploy • • • • • • • 9 Identify areas, equipment of significant energy use and parameters need to test. Monitor and record data of energy consumption. Conduct energy audit (energy performance, energy savings solution) Establish objectives and plan Implement plan Motivate and communicate energy savings Evaluate efficiency of energy management system STANDARD ON ENERGY MANAGEMENT SYSTEM ISO 50001: 2011 STANDARD International standard on energy management system, issued in 6/2011 Old energy management system Present energy management system Future energy management system Countries/Scope Standard Denmark DS2403:2001 Sweden SS627750:2003 Ireland IS 393:2005 Spain UNE 216301:2007 UE-27 EN 16001 Effect from 07/2009 China GB / T 23331-2009 Effect from 11/2009 United State ANSI/SME 2000 Effect from 2008 From 2010 World ISO 50001 (from EN 16001) Issued in 06/2011 STRUCTURE: 1. Scope 2. Normative references 3. Terms and definitions 4. Energy management system requirements 4.1. General requirements 4.2. Management responsibility 4.3. Energy policy 4.4. Energy planning 4.5. Implementation and operation 4.6. Checking 4.7. Management review Annex provide guidance for using standard 10 EFFECT OF ENERGY CONSERVATION OF BEMS Primary energy consumption (X103GJ) Primary energy consumption of 201 building whole 8.4% Reducing by 11.2% Source:NEDO Actual Result BEMS are installed in 80% of large buildings. Introduction of V-BEMS in Vietnam Cooling Tower A A A T T T T T T T A A A secondary chilled water pump T T Chiller condenser Water pumps T Chiller T A AHU FCU Chiller T A A A A T A Methods of energy savings: Optimization of the chiller number control. Optimization of chilled water temperature. Chilled water pump variable control. Condenser water pump variable control. Management of performance of chiller COP. primary chilled water pump T Data Analysis Cooling load Vs. Outdoor air temp Chiller COP Vs. Cooling load Chiller COP Vs. Condenser Ent water temp Chiller COP Vs. Evap Lvg temp. Water transportation Factor Cooling Load Vs. WTF Condenser water temp Secondary chilled water Temp System power consumption Cooling load Vs. occupancy rate Source:Hibiya Introduction of V-BEMS in Vietnam Typical: Legend Hotel In Ho Chi Minh City: 280 rooms Content Cost Equipment 20,000 Install Total 5,000 USD 25,000 Expected savings 13,000USD/ye ar Payback < 2 years Source:Hibiya TELEVISION CENTER BUILDING Objectives In 2011, 100% lamps are replaced to high efficiency lamps Area of 20,000m2 1 basement, 1 ground floor, 14 floors Inaugurated in 2006 Save more than 10% of electricity consumption of cabinet air conditioner – 217 units Reduce 10% of capacity utilization of water chiller system Save 3-5% from the existing transformers Research on using solar power to supply electricity for small loads in early 2013 Deploy the project to upgrade and expand BEMS for entire building SOFTWARE FOR MANAGING AND MONITORING ENERGY • • • • Manage electrical system Measure electricity Attach additional measuring equipment MacPiu of Ducati, measure electricity in the old building. WINCC (Siemen) INSIGHT (Siemen) Energy • Manage air conditioning systems, electrical system of daily activities, Gaz system, CO2 pollution levels, pumping system, pressure fan. Monitor electricity at loading branch SIPASS (Siemen) • • • • • Statistic materials & components. Manage equipment Set maintainence schedule. Record history of equipment • QLBT&SC (HTV) Manage lighting system (monitor & remote control). Manage entrance RESULTS Reduce 16% of electricity consumption in 2009 against to in 2008. The average electrical performance from 7.16 kWh/m2 (2008) to 14.34 kWh/m2 (2009) Electricity (kWh) THE RESULT Chart of electrical consumption of building in 2008 - 2009 Month Thank you for your attention