Case 3

advertisement

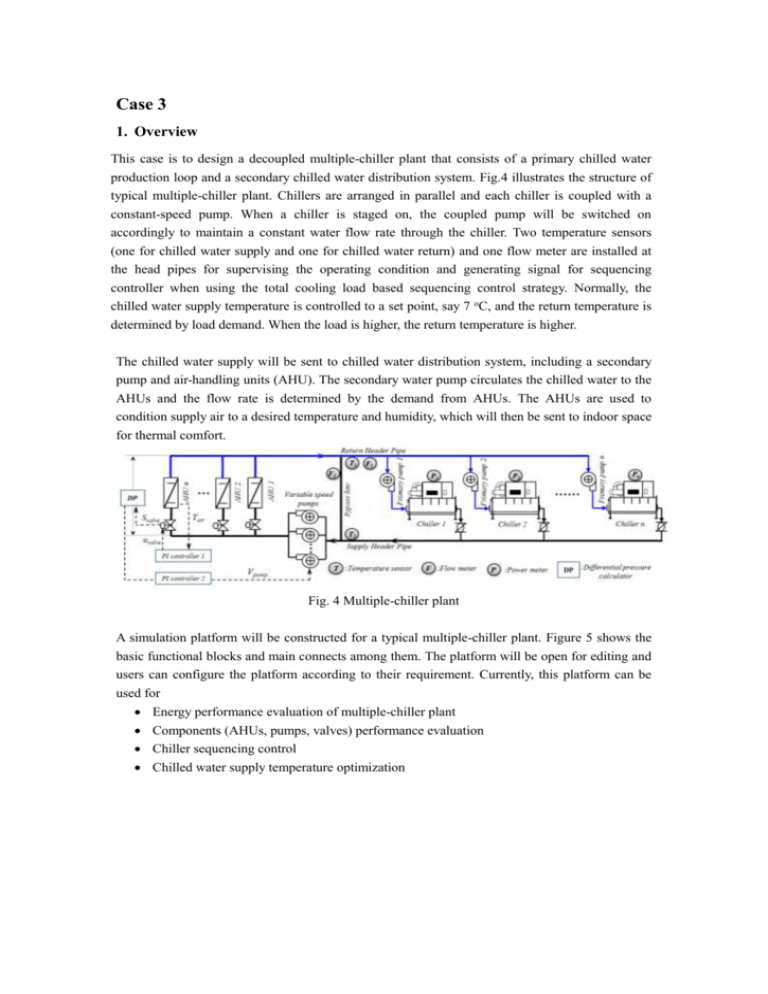

Case 3 1. Overview This case is to design a decoupled multiple-chiller plant that consists of a primary chilled water production loop and a secondary chilled water distribution system. Fig.4 illustrates the structure of typical multiple-chiller plant. Chillers are arranged in parallel and each chiller is coupled with a constant-speed pump. When a chiller is staged on, the coupled pump will be switched on accordingly to maintain a constant water flow rate through the chiller. Two temperature sensors (one for chilled water supply and one for chilled water return) and one flow meter are installed at the head pipes for supervising the operating condition and generating signal for sequencing controller when using the total cooling load based sequencing control strategy. Normally, the chilled water supply temperature is controlled to a set point, say 7 oC, and the return temperature is determined by load demand. When the load is higher, the return temperature is higher. The chilled water supply will be sent to chilled water distribution system, including a secondary pump and air-handling units (AHU). The secondary water pump circulates the chilled water to the AHUs and the flow rate is determined by the demand from AHUs. The AHUs are used to condition supply air to a desired temperature and humidity, which will then be sent to indoor space for thermal comfort. Fig. 4 Multiple-chiller plant A simulation platform will be constructed for a typical multiple-chiller plant. Figure 5 shows the basic functional blocks and main connects among them. The platform will be open for editing and users can configure the platform according to their requirement. Currently, this platform can be used for Energy performance evaluation of multiple-chiller plant Components (AHUs, pumps, valves) performance evaluation Chiller sequencing control Chilled water supply temperature optimization Fig. 5 Simulation platform (TRNSYS) 2. Simulation Platform This project is constructed on TRNSYS 17 and the chiller sequencing control strategy is coded in Matlab 2010. Figure 1 Simulation platform in TRNSYS 17 3. Mode Used: Type Name Functions Route Type 9c Cooling load To read the load profile from .txt documents Utility->Data readers->Genetic Data files-> Free format Equation Air Flow rate Calculate air flow rate with thermal balance equation Manu-> Assembly-> Insert new equation Type 744 Variable speed fan To supplying return air to the coils Hydronic Library[TESS] ->Fans-> input the flow rate Type 646 Return air diverter To divert return air to different coils Hydronic Library[TESS] ->Valves->Diverting valve->air Type 648 Supply air mixer To mix supply air from different coils Hydronic Library[TESS] ->Valves->mixing valve->air Type 52a coil To cool the return air HVAC->cooling coils-> detailed Type 23 Tempt controller /DP controller To control the supply air at the setpoint Controllers->PID controller Type 741 Variable speed pump To distribute chilled water to coils Hydronic Library [TESS] ->Pumps -> variable speed-> Power from efficiency and pressure drop Type 155 Chiller sequencing controller To implement a link with Matlab (.m). Utility-> Calling external programs ->Matlab Type 654 Constant pump To provide constant flowrate to chillers Hydronic Library [TESS] ->Pumps-> sets the mass flowrate -> single speed ->constant power Type 666 chiller To provide cooling and maintain the chilled water supply temperature at setpoint HVAC library[TESS] ->chillers -> water-cooled chiller Type 65c Outputs To online plot and output the required data Output->Online plotter with file -> not units Please Note that: All the parameters setting can be seen when double click the component in the simulation platform. Therefore, no parameters setting will be introduced in this guidebook. The design of this platform is based on a typical system with real cooling load. For different cases, the configuration can be modified and tests for different chiller plants are flexible. All the parameters of the used components can be modified and the performances of the components can be evaluated according to the parameter setting. The input documents for Data reader and Matlab linker should be put in the same folder of the project. 4. Examples 1) PID controller performance evaluation The temperature controller tends to control the supply air to its setpoint, 16oC. But the control performance is determined by the tuning conditions of the PI controller. When the parameters of the PI controller are changed, the tracking setpoint responses are different. As shown in Figure 2, the red curve illustrates the controlled supply air temperature and the blue curve is the load condition in a week. It is clear that when the gain constant is set to be -0.03, the control result is much better than that when the gain constant is -0.01. Figure 2. a) Supply air temperature when the PI gain constant is -0.03; b) Supply air temperature when the PI gain constant is -0.01. 2) Chiller sequencing control The control performance of chiller sequencing control strategies can be evaluated in this simulation platform. For instance, the total cooling load-based control strategy was coded in Matlab with an “.m” document (Q_basedControl.m) and link to the simulation platform. Figure 3 shows that this control strategy can stage chiller on or off according to the cooling load condition. Figure 3. Chiller sequencing control results