Mr. Tony Young, VP Facilities Planning and Operations Mr. John

advertisement

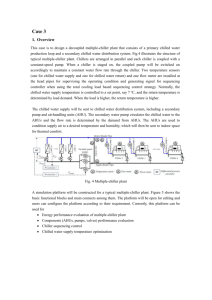

Mr. Tony Young, VP Facilities Planning and Operations Mr. John Lyon, Manager of Operations Carnegie Museums of Pittsburgh 4400 Forbes Avenue Pittsburgh, PA 15222 Introduction This report is intended to share the discoveries and solutions that arose during the summer 2015 commissioning of the new chilled water plant designed by CJL Engineering at The Carnegie Museum of Art & Natural History in Pittsburgh, PA. The commissioning for this project was executed during the month of June, from June 1st thru June 30th, and was conducted by Joe Ruis of CJL Engineering along with CS&E building automation technicians Jason Lanz and Joe Patz. The overall plant system narrative provided by CS&E as a CJL requirement of the commissioning process will lay the framework of the system provided for better understanding of the commissioning troubleshooting, discoveries, suggestions and solutions. Carnegie Museum Chiller Plant System Narrative Cooling for the chilled water system at Carnegie Museum of Natural History is provided by three distinctly different chillers in order to satisfy the overall load for the site. Chillers #1 and #3 are new Trane centrifugal chillers (1,250 tons and 850 tons respectively) that were installed during this project and operate with variable primary flow through their evaporators. Chiller #1 is the larger of the two, and as such typically serves as the lead chiller in high load conditions with the smaller chiller (#3) used to supplement in order to match required load. In conditions with lower cooling loads, most notably swing months, chiller #3 will serve the building until it reaches its maximum output. In winter months, free cooling will be available to the facility due to a heat exchanger installed in this project. In some cases, existing chiller #2 will operate to meet the plant load, but this will be done in order to provide adequate runtime for the machine and verify its proper operation. The plant is put into “high” mode, “low” mode, and “chiller #2” mode by an operator selection made through the BAS color-graphic user interface based on environmental load conditions that can also be accessed through the BAS user interface. All scenarios for staging, loading, and unloading chillers with varying loads are described within the sequence of operations, and all logic decisions are made in order to optimize the performance of the plant by minimizing the energy consumption of the entire system while maintaining the necessary chilled water system supply water temperature set-point. One major system contributor to the reduction of system energy is the variable flow of chilled water through the facility, originating in this case with the system primary pumps at the chiller (variable primary as opposed to decoupled pumping). The primary pumps modulate their GPM supplied to the system based on maintaining a remote differential pressure set-point, and five remote bypass valves 1 modulate their position to ensure that the minimum amount of flow passes through the evaporators of the operating chillers at all times. This configuration, along with the efficient new chillers, enables a low temperature of supply water temperature to be pumped throughout the facility to satisfy required load using as little pumping energy as necessary. On the condenser water side, only one of the pumps (condenser water pump #2) is equipped with a VFD, which means that variable condenser water flow is capable as well but only when low load conditions allow for chiller #3 to run alone or to supplement required flow when a constant volume condenser water pump can no longer satisfy flow requirements alone. Flow is measured and validated by means of Onicon flow meters (insertion type and inline type) installed throughout the system, including flow meters serving Zones A, B, and C, which are used to generate and provide billing reports to the Carnegie Library, The Carnegie Museum of Art, and The Carnegie Museum of Natural History. Heat is rejected from the chilled water system by means of existing cooling towers equipped with new control devices, valves, and variable speed fans. CWFT temperatures have been set to provide water that is 7 degrees warmer than the outside air wet bulb temperature, which is a solution that aims to minimize how hard the cooling tower must work to reject heat, as the new chiller componentry in the project performs at very high efficiencies. With the chilled water, pumping, and cooling tower contributions all being considered in one system, plant energy performance will be monitored and trended over the varying cooling loads it will experience over the course of a calendar year. Once actual plant performance has been observed and considered in actual practice, results may indicate that setpoints or conditions may need to be altered in order to further optimize plant performance in either allocating cooling requirements or enhancing energy optimization. The end result will provide a chiller plant system that is controlled to create a preferred environment for the art and installations at The Carnegie Museum and a comfortable experience for its guests in all seasons, while providing considerable energy savings by means of a system approach at the chilled water plant utilizing efficient new equipment and improved engineering methodology. Commissioning Discoveries and Solutions Commissioning checkout procedures were provided by CJL Engineering and executed by CS&E in the presence of CJL and The Carnegie Museum over the month of June. The satisfactory results of those procedures, as well as the accompanying notes, have been documented and provided as a part of this project. This process involved check-outs for point-to-point graphic capabilities, sequencing performance, manual observation of actuator performance, sensor calibration, etc. and is covered in great detail with the commissioning documents. The intent of this report is to supplement that information with discoveries and solutions that will hopefully improve The Carnegie Museum’s understanding of their plant and generate best practices for CJL Engineering’s and CS&E’s processes moving forward. 2 System Graphics System graphics are the building operator’s interface to the entire system, and as such it is very important that they are useful and intuitive. The design and commissioning requirements assured that The Museum will receive a useful system that programs and achieves the specification. Beyond this, CMNH will also benefit from several collaborations between CJL Engineering and CS&E during the commissioning phase that improved the ease of use and functionality of the BAS graphic screens. The first of these improvements during commissioning arose out of suggestions from Larry Sipe of CJL Engineering to standardize each screen so that the same, standard information could be found at the same location at each screen, even though they have different purposes. This suggestion was embraced by Joe Patz and applied for all screens, making it easier to get a grasp of the interface faster and to develop an intuitive nature for where certain access points are found. Larry also suggested the implementation of a “weather station” screen that allowed Joe to free up more space on each screen for access to and information about points more specific to the CMNH plant itself. CS&E will be implementing this standardized panel approach and weather station approach moving forward due to the benefits it created for The Carnegie Museum’s interface and because it makes for better, more efficient graphic creation. Another outcome from this could be for CJL Engineering to potentially create a graphic layout screen page in their specification that details how a panel should look that would ultimately be very similar to what has been done here at The Museum. This would be a progressive step and something that has not been done by any other engineering firm in Western Pennsylvania, but one that could assure that graphics are made to the high standards set here at The Carnegie Museum. In any event, the collaborative nature and discussion of the graphic designs during commissioning have yielded an improved and highly useful product for The Carnegie Museum. Flow Meters and Refrigerant Monitoring Onicon insertion Flow Meters FM-13 and FM-14 (Zone C and Total Condenser water flow, respectively) needed a good amount of troubleshooting and field-verification until the expected flow values were observed. FM-13 was installed perpendicular to the direction of flow, and there was confusion as to the actual pipe size where FM-14 was installed, so new programs were sent from the Onicon factory and installed via laptop in the field to load the proper flow curves. FM-14 is a previouslyexisting flow meter that was sent back to Onicon for re-calibration as a value-engineering measure. As for the startup and integration of refrigerant monitoring system into the BAS, Norm Mahfood of MSA was a good technical resource. This plant employs continuous refrigerant leak sensing at each chiller, which is a very accurate and thorough method of leak detection that benefited from the inclusion of Norm’s subject matter expertise. 3 CHWS Set-point Considerations The commissioning team tested chilled water reset and supplying slightly warmer (i.e. 42 degree Fahrenheit) water from the plant to the facility, and during days in the high 80’s humidity in the facility rose too quickly. John Lyon reported complaints of printers not being able to print and papers beginning to fold within 24 hours of the change, so the plant was reset again back to 40 degrees. According to John, the envelope of the building is very poor, and humidity has a tendency to build very quickly. A reset schedule of 40, 42, and 45 degree water was considered early in the process but seems inadvisable due to the quick rise of humidity issues experienced under operating plant conditions. Due to the sensitivity of maintaining this low supply water temperature, additional automatic programming was implemented during the commissioning process. Under almost all circumstances, the selection of “low”, “high” or “chiller #2” mode conditions is exclusively user-selectable. However, with how quickly plant supply temperature could rise during observation and how quickly higher supply water temperatures led to humidity concerns in the humidity-vulnerable environment that we find in a museum, an automatic transition from “low” mode to “high” mode was implemented. This automatic transition will occur if the plant, while operating with only chiller #3, fails to reach chilled water setpoint + 3 degrees F for 20 minutes. In this event, chiller #1 will stage on and the plant will find itself operating in “high” load. No other such reversal, for instance, an automatic shift from “high” mode to “low” mode has or should be implemented past what is called for in the specifications, as these changes are not critical to satisfying the museum’s temperature and humidity. “High” Load Chiller De-staging During high temperature and humidity demands observed throughout commissioning, chiller #1 and chiller #3 are very capable of maintaining chilled water set-point in “high” mode with two cooling towers, two chilled water pumps, and two condenser water pumps in operation. With set-point maintained, due to the nature of the facility, it becomes a bit cloudy to determine when the appropriate time arises to stage chiller #3 off. For instance, with set-point easily maintained and a plant load in tonnage that exceeds chiller #1’s capacity, if chiller #3 is staged off it will need to be brought on again very quickly to get the plant back down to the appropriate temperature. With 30-minute time delays for re-starts, this makes things more dangerous than necessary should plant temperature begin to rise. This would also lead to a scenario where chiller #3 experiences more starts that necessary, potentially adversely impacting the machine. With this said, there is no use in leaving both chillers in operation to maintain the setpoint when the total plant tonnage is steadily between 850 tons and 1,250 tons, as chiller #1 can handle that total alone. The commissioning team’s solution was to program that, when in high load with two chillers operating, chiller #3 shall be staged off when plant load drops below 900 (adj.) tons. This prevents risk of losing supply water temperature and repetitive staging on and off of chiller #3, but assures that CHWS temperature will be maintained consistently with the appropriate amount of energy consumed by the chillers. 4 The 30-minute time delay for chiller restarts, through discussions with Trane during the commissioning process, is also something that can be shortened if necessary during regular plant operation. It was built into the sequences as a safety measure to prevent cycling the machines, but became a bit of a problem during the commissioning process since more tests were being conducted and upon any types of failure the plant could be left without cooling for far too long. In fact, on certain occasions by the time chiller #3 would be called back on to recover load during tests, it would already be locked out due to the load being too high. Because of these operator seat troubleshooting issues, the commissioning team contacted Trane and learned that somewhere between 5 and 15 minutes is probably sufficient for their centrifugal chillers. Efficiency Gains in Cooling Tower Considerations The Carnegie Museum’s chiller plant kW/ton energy efficiency performance will benefit from continuous testing and trending, as has already been evidenced during the commissioning process. By flowing condenser water across two cooling tower cells as opposed to one, the commissioning team was able to create a situation where the CWFT was able to reach set-point and the VFD’s on the fans were set to around 75% each, as opposed to one cooling tower fan running full-bore 100%. This not only added redundancy to the system and allowed water to reach set-point back to the chiller, but consumed less energy at the tower fans and allowed the chiller to run more efficiently, consistently showing lower plant overall kW/ton readings than in the base case with which the team originally started. Upon completion of commissioning, it will be in The Carnegie Museum’s best interest to continue the consideration of different plant methods, particularly pump and fan speed outputs, to distribute more or less of the plant load to components that run at different efficiencies. The graphic interface gives a very clear real-time view, with kW readings at the chillers, pumps, and cooling tower fans as well as an overall plant performance in kW/ton on the main chilled water system screen. But the ability to trend energy consumption overtime as plant load varies will provide more opportunities to test theories. Surging Chiller #3 Under high load conditions with chillers #1 and #3 running, the plant experienced surging behavior from the smaller chiller #3. Trane came out to review the situation to determine the cause, whether the surging could be stopped, and the danger of the event. 5