Paul Basherian, M.E.P.C.A.D. - Welcome

advertisement

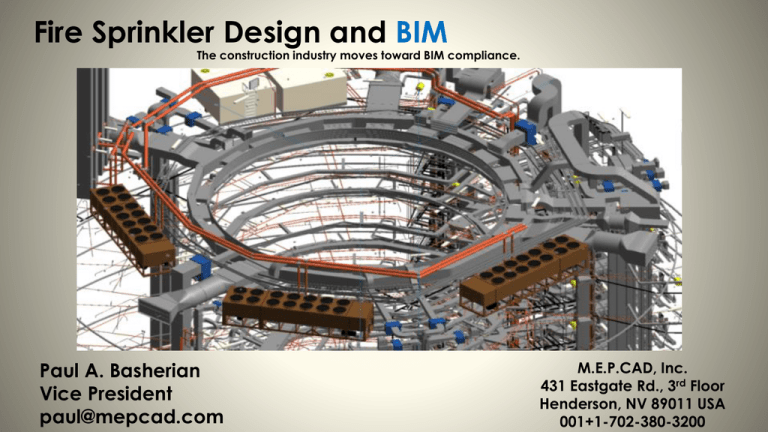

Fire Sprinkler Design and BIM The construction industry moves toward BIM compliance. Paul A. Basherian Vice President paul@mepcad.com M.E.P.CAD, Inc. 431 Eastgate Rd., 3rd Floor Henderson, NV 89011 USA 001+1-702-380-3200 Building Information Modelling (BIM) Becoming common for projects to be designed in 3D BIM Ready or not, the construction industry is rapidly moving away from traditional 2D CAD design tools and toward this modern method of design UK market is moving toward BIM compliance Building Information Modelling (BIM) 3D: intelligent object building model for spatial coordination 4D: Construction Time and Scheduling 5D: Cost 6D: As-Built Working Model for Maintenance and Building Life Cycle Possibly More Levels to Come Level of Detail(LOD) Typically, Too Much Information (detail) is provided for sub-contractors in the working model High LOD = very large files (> 1GB!) Requires a significant investment in hardware and training Ideally, Extract only Trade-Specific information from model No industry standard for BIM Levels! Other standards and levels: COBie (0 – 3), 1-4, G0 – G3, & more… Why Change? Why should our industry move away from traditional design tools? Why should we abandon years of investment in software and training? Mainstream Architectural BIM software is very powerful, but somewhat limited for a fire sprinkler designer No welded outlets No complex hydraulic calculations involving unlimited loops, pumps, multiple water sources, and more No curved pipe No stocklisting for fabrication Massive file sizes : workflow slows to a crawl Limitations of 2D CAD – “The Hammer” “When all you have is a Hammer, everything starts to look like a Nail” Dependent on a command-driven, layer-dependent 2D CAD engine, which is not BIM The 3rd dimension must be constantly thought about since it is not on the screen during design and within the design program Requires training for 2D CAD engine, the fire sprinkler design add-on program, a separate coordination program, and possibly the program used to create the building model No internal intelligence of elements Draw with lines, blocks, and attribute tags (electronic hand drafting) CAD = Computer Aided (Hand) Drafting Limitations of 2D CAD • • No immediate feedback for spatial coordination – info must be sent to: External coordination program does not allow modifications, hydraulic calculations, or fabrication stocklisting • Time consuming back and forth (2D – 3D) process FLOWCHART Traditional Coordination 2D Design Repeat Create 3D model, then open and view in coordination program All revisions must be made in 2D design program – repeat process as many times as necessary until design is collision-free Yes Collisions? Design Repeat Convert Check No 2D Design 3D Design Maintain 2 versions of the same system (2D and 3D)! FLOWCHART BIM-Compliant Coordination Design Complete! Analysis Revisions 3D Design Collisions? Yes No Done! All revisions made in design environment for immediate hydraulic and cost analysis Maintain only 1 version of the system (3D BIM) Automobile Design Analogy Back to the Old Drawing Board Good Not Good Definitely Not Good Brilliant The challenges of 3D building plans • • Increasingly complex buildings Reveals the limitations of 2D CAD The challenges of 3D building plans The same building in 2D BIM for your Business Model • Resisting this only serves to stifle innovation and limit your company’s flexibility. Both are bad news for a Business Model. • • What does all of this mean for your Business Model? Transitioning to modern technology before your competition does will allow you to acquire or maintain a competitive advantage. Business Model Analysis – The Kodak Corp. • • • • • • Perfect example of a company resisting change. Initially ignored the shift away from film and toward digital imaging Ultimately cost them their position at the top. Massive legacy costs in hardware Skepticism and dismissal of new technology Instead of a bigger and better hammer, a completely different tool was required Benefits of 3D BIM – “The Anti-Hammer Device” a.k.a. The Right Tool for the Job • • • BIM is more than just nice looking 3D pictures or models. Improved system design through better collaboration with all trades Coordination becomes a Team Effort Benefits of 3D BIM – “The Anti-Hammer Device” a.k.a. The Right Tool for the Job • • • Risk is reduced by eliminating unknowns Increased accuracy in ordering materials and fabrication Delivery of products and services are accelerated through better efficiency • Fewer changes on job site – less wasted material and labor (Increased Profits) • Better predictability of costs and scheduling – again, due to the elimination of unknowns BIM for Fire Sprinkler Design • Instead of lines representing pipes, blocks for fittings, inherent properties instead of attribute tags, full BIM compliance requires intelligent parts in a threedimensional model. This is the “I” in BIM. Without this, the model is just a 3D picture. • Intelligent parts contain the product data sheet, hydraulic properties, weight, cost, and more. BIM for Fire Sprinkler Design Water Flowing • No Water Flow Each parameter can be changed, which changes the object’s appearance and behavior. For example, a check valve would behave exactly as its real world counterpart would. If it’s oriented in the wrong direction, the clapper within the valve should close and not allow the flow of water in the opposite direction. BIM for Fire Sprinkler Design • Fire pumps, water storage tanks (including water level information to establish QMax and QCap data), fire sprinklers, hose valves, etc. should all know their role in the system and interact with each other appropriately. Fire Sprinkler Design and BIM – Q&A The construction industry moves toward BIM compliance. Kevin Maddux, PE President kmaddux@mepcad.com M.E.P.CAD, Inc. 431 Eastgate Rd., 3rd Floor Henderson, NV 89011 USA 001+1-702-380-3200 Paul A. Basherian Vice President paul@mepcad.com