skogestad-education-mexico2012-admidiq

advertisement

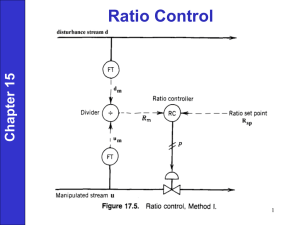

PSE and PROCESS CONTROL Sigurd Skogestad Department of Chemical Engineering Norwegian University of Science and Tecnology (NTNU) Trondheim, Norway PSE Education Session AMIDIQ 2012, Mexico, May 2012 1 PROCESS CONTROL Theory Left side of brain = logical 3 PROCESS CONTROL Control structures + Practise Right side of brain = creative 4 PROCESS CONTROL Theory & practise Combine both sides! 5 Process control course. Four main elements: 1. PROCESS – – Process dynamics: Step responses, simulation Process control structures: Flowsheet (P&ID*). PID tuning 2. CONTROL – theory: Feedback idea, block diagrams, stability, transfer functions (Laplace), feedforward/cascade/frequency response, identification, multivariable control (MPC) 3. PRACTISE – – Laboratory Simulation (Aspen, Hysys/Unisim..) 4. SYSTEMS – Modelling principles, Solution. State space models, linearization (ABCD), optimization 6 *P&ID: Process and Instrumentation Diagrams Difficult course • Many new concepts – Inputs and outputs, causality – Feedback – Stability • New mathematics – Laplace – Frequency analysis – System theory (ABCD) • • 7 And all of this combined with practise: operation of real plants Too much for one course? I teach the course in two parts 1. ”Process control” crash course (3 weeks) – Focus on process control structures (P&ID) 2. Standard process control course (11 weeks) – 8 Focus on theory Crash course process control Sigurd Skogestad Institutt for kjemisk prosessteknologi Rom K4-211 skoge@ntnu.no More information (literature, old exams, etc.): • www.nt.ntnu.no/users/skoge/prosessregulering_lynkurs 9 Why control? • • Until now: Design of process. Assume steady-state Now: Operation Actual value(dynamic) Steady-state (average) time “Disturbances” (d’s) 10 Example: Control of shower temperature MVs, CVs and control 11 CLASSIFICATION OF VARIABLES flow in Hs H LC flow out OUTFLOW: INPUT FOR CONTROL INFLOW: DISTURBANCE 12 BLOCK DIAGRAMS d FEEDBACK (measure output): ys Desired value Setpoint ys-ym Controller u error input (MV) (brain) ym measured output measured disturbance d Measurement device Controller (brain) 13 output (CV) Measurement device FEEDFORWARD (measure disturbance): dm y Process (shower) u input (MV) Process (shower) •All lines: Signals (information) •Blocks: controllers and process •Do not confuse block diagram (lines are signals) with flowsheet (lines are flows); see below y output (CV) Most important control structures 1. 2. 3. 14 Feedback control Ratio control (special case of feedforward) Cascade control Process and instrumentation diagram (P&ID) (flowsheet) T (measured CV) Ts (setpoint CV) TC MV (could be valve) 2nd letter: C: controller I: indicator (measurement) 15 1st letter: Controlled variable (CV). What we are trying to control (keep constant) T: temperature F: flow L: level P: pressure DP: differential pressure (Δp) C: composition X: quality H: enthalpy/energy Typical distillation control: Two-point composition control LV-configuration with inner T-loop LV CC Ts TC CC 16 xB xD Process dynamics (response) • “Things take time” • Step response (step in u): – k = Δy(∞)/ Δu – process gain – - process time constant (63%) – - process time delay • • Time constant : Often equal to residence time = V[m3]/q[m3/s] (but not always!) Can find (and k) from balance equations: – 17 Rearrange to match standard form of 1st order linear differential equation: Pairing of variables Main rule: “Pair close” The response (from input to output) should be fast, large and in one direction. Avoid dead time and inverse responses! 18 Model-based tuning (SIMC rule) • From step response – k = Δy(∞)/ Δu – process gain – - process time constant (63%) – - process time delay • Proposed SIMC controller tunings 19 k = Δy(∞)/ Δu Process Control crash course (3 weeks): 1. Process operation: Why do we need process control? 2. Classification of variables (inputs, outputs, disturbances, measurements) 3. Feedback versus feedforward control 4. Block diagram representation (information diagrams, causality) 5. Flowsheet representation (process & instrumentation diagrams) 6. Single-loop control: Pairing of input and outputs 7. More advanced control: Ratio control, Cascade control, 8. The control hiearchy (optimization, advanced control, basic control) 9. Process dynamics (basics): first- and second order systems, time delay, identification 10. Process modelling: balance principle 11. PID control and tuning 12. Simulation 20 Control theory (11 weeks) “standard course” 13. Laplace transforms, transfer functions 14. Closed-loop response, derivation of PID tuning rules 15. Pros and cons of high gain feedback. Stability. Change dynamics. Biological systems 16. Dynamic systems (theory). poles, zeros, state space, observability, controllability 17. Control systems (theory), frequency analysis, stability conditions, robustness 18. Controller implementation: discrete control, windup, bumpless transfer 19. Identification (theory) 20. Multivariable control: interactions, MPC 21 + 3. Practise • LAB ?!! – At least have demonstration • SIMULATIONS ?!! – Time consuming 22 + 4. Systems engineering • General modelling principles, DAE-system • Solution of dynamic models (integration) • Linearization, State space models (deviation variables) • Optimization 23 Conclusion: Process systems engineering (PSE) and process control • Process control is a key course – Engineers must know some control! • Usually too little time to focus on systems issues – Need advanced course to cover process systems aspects of process control 24