ECHM 451 Chemical Engineering Process Dynamics and Control

advertisement

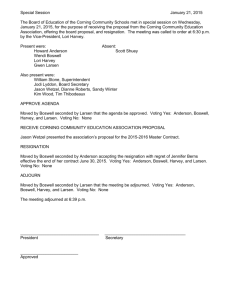

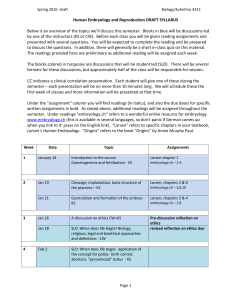

ECHM 451 Chemical Engineering Process Dynamics and Control Spring, 2014 REID 104 What is Process Control? • Techniques and technology to control a process. • Example: light switch • Example: coffee maker • This class will focus on automated control About me… • • • • Office: COBL 310 Phone: 406-994-7902 Email: jeff.heys@gmail.com Office hours: – Tuesday 11:00am – 12:00pm – Thursday 1:00pm – 2:30pm – Open office policy, but focus on TTh About this class • Meet twice per week on Tuesday and Thursday. • Scheduled time 9:25-10:40 (typically less) • http://www.coe.montana.edu/jeffrey.heys/web451 • “Typical class”…. Lectures, homework, 2 exams including the final, and a project • Lecture capture? History • 1995: Ron Larsen took a sabbatical with Dow focused on process control • 1996: I took the course from Dr. Larsen the first time he taught it • 1996 – 2011: Dr. Larsen refined and improved the course and wrote a textbook along the way. • 2011-12: Dr. Larsen promoted to associate provost 2013 • I’m teaching this course for the third time (some experience at Stone Container). • We will use Dr. Larsen’s book (pick up in main office…$14.50) • Read the syllabus and schedule • Homework policy (boxes, staple, 1 or 2 per page, etc…) • Check your MSU email account frequently Chapter 1 • Example #1: Thermostat (On/Off control with set points (SP)) • Example #2: Cruise control (proportional control) 𝑚𝑔𝑎𝑠 = 𝑘 ⋅ 𝑣𝑆𝑃 − 𝑣𝑎𝑐𝑡𝑢𝑎𝑙 + 𝑚𝑠𝑒𝑡 • Determining 𝑘 is difficult Why? 1. Convenience (and lower labor costs) 2. Safety (many industrial accidents could have been prevented with better process controls) 3. Consistent quality (computers are just better at mundane details) Why? • Most chemical and biological engineers are not process control experts, but they need to understand the basics! • Production engineering: responsible for day-today operations. Need to understand process controls to deal with daily issues. • Process engineer: longer term view toward continuous process improvement…these improvements often involve new or modified process controls. Specialists • Some chemical and biological engineers become process control engineers – focus on improving process control systems and implementing standard systems • Even fewer become process control specialists – implement solutions for specialized, nonstandard, control situations. Types of Process Controls 1. 2. 3. 4. Manual control (open loop) On/Off control (closed feedback loop) PID control (chapters 2-9) (closed feedback loop) Dynamic model-based control (closed feedforward loop) 1. Empirical models (e.g., cold shower) 2. Phenomenological models This book… • Focus is on information needed by process and production engineers (i.e., not specialists) • Other books focus on process modeling and Laplace transforms first, and then they discuss PID controls for those processes (and the result are engineers that cannot tune a controller without a model). Larsen vs. Luyben, Riggs, etc. Traditional • Process Modeling • Convert model to Laplace space • Learn about hardware/software (briefly) • Analysis of hardware/software in Laplace space Larsen • Learn about hardware/software (briefly) • Learn basics for analysis of hardware/software • Process Modeling • Convert model to Laplace space • Analysis of hardware/software in Laplace space Basic Control System • Oil heater that uses steam Basic Control System • #1 – we need a sensor (and we cannot measure everything, like entropy or fugacity) Basic Control System • #2 – we need a controller (e.g., PID controller) Basic Control System • #3 – we need something to control (and we cannot control everything like steam T and P)