过程动态特性的数学描述及其经典测试法

advertisement

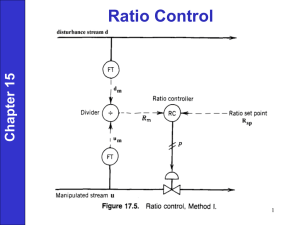

Introduction for Process Control Systems 过程控制系统概论 Shen Guo-jiang Institute of Industrial Control, Zhejiang University Contents Origin of Process Control Systems Important Terms and Objective of Process Control Systems Description of Process Control Systems Types of Control Strategies Course Tasks Systems and Control Systems Outputs Z U Y Inputs Systems D Control Systems examples ? Application of control system The military: flight control Mechanical engineering: centrifugal governor (Watt) Electricity and electronics Process industry (including: petroleum, chemical, metallurgy, pharmaceutical, environmental protection, etc.) Economy and management system: CPI levels of control Other… Origin of Process Control Systems Purpose: To maintain the level at a desired operating value, when the inlet flow(输入流 量) changes. Manual Operation: (1) Measure the level by a water gauge and the eye (水位表); (2) Compare the level to its desired value in the brain; (3) Based on this comparison, decide what to do to correct for any deviation (偏差); (4) Manipulate the outlet valve (输 出阀) to correct for the deviation. Limitations with Manual Control Require the operator to look frequently at the level to take corrective action whenever it deviates from the desired value; Different operators would make different decisions as to how to move the outlet valve, resulting in inconsistent operation (操作的不一致 性); Require a large number of operators to maintain hundreds of variables in most process plants at a desired value. Solution ? Automatic Control System Solution: Design a control system to accomplish this control automatically without requiring intervention from the operator. Qi hsp h LT 21 Qo LC 21 Three basic components of all control systems: • a sensor / transmitter: the “eye” of the control system, • a controller: the “brain” of the control system, • final control element: often a control valve. Feedback Control Process 1. Measure the level by a sensor (传感器) and convert the output from the sensor to an electric signal by a transmitter (变送器) ; 2. The controller(控制器/调节器) then receives the signal and compares it with the value desired; 3. Depending on this comparison, Qi the controller decides what to do to correct for any deviation; LT h 21 4. Based on this decision, it sends a signal to the final control element(执行单元), e. g., a Qo control valve. hsp LC 21 Three basic operations in every type of control system Measurement (测量,M) Measuring the variable to be controlled is usually done by the combination of sensor and transmitter. Decision (决策,D) Based on the Measurement the controller decides what to do to maintain the variable at its desired value. Action (动作/执行,A) As a result of the controller’s decision, the system must then take an action. This is usually accomplished by the final control element. The action taken must come back and affect the measurement. Important Terms of Automatic Process Control Controlled Variable (CV, 被控变量/受控变量) Setpoint (SP,设定值/给定值) Manipulated Variable (MV,操纵变量/操作变 量) The variable that must be maintained or controlled at some desired value. The desired value of the controlled variable. The variable used to maintain the controlled variable at its setpoint. Disturbance (DV,扰动/扰动变量) Any variable that causes the controlled variable to deviate away from its setpoint. Objective of Process Control Systems The objective of an automatic process control system is to adjust the manipulated variable to maintain the controlled variable at its set point in spite of disturbances. Why automatic control is important: 1) Safety. Prevent injury to plant personnel and damage to the process equipment, and protect the environment by minimizing wastes. 2) Product Quality. 3) Minimum Cost. Example 1.1 Psp Pm PC 51 PT 51 u F1 P2 f2 P P1 f1 F2 Variable relations are as follows: dP V K1 F1 K 2 F2 dt F1 KV 1 f1 P1 P f1 100 u For the above pressure control system, please describe its CV, F2 KV 2 f 2 P P2 SP, MV, DVs, control diagram as well as control objective. Discuss the solution ? Control Diagram #1 for Example 1.1 f2 P2 Controlled Process KV 2 f 2 P P2 P1 Psp e(t) + PC 51 u(t) Control Valve f1 P F2 KV1 f1 P1 P _ F1 P(t) dP K 1 F1 K 2 F2 V dt P Pm PT 51 Point out its MV, DVs ? Control Diagram #2 for Example 1.1 Psp + PC 51 _ u(t) Control Valve P1 P2 f2 Disturbance Path (干扰通道) f1 Control Path (控制通道) + + Controlled Process Pm PT 51 P(t) Control Diagram #3 for Example 1.1 P1, P2, f2 Disturbance Path Psp + PC 51 _ u(t) Control Valve F1 Control Path + + Controlled Process Pm PT 51 Discuss its correctness P(t) Ex. 1.2: Temperature Control System for a Heat Exchanger Tsp u(t) TC 22 Steam RV Problem: point out CV, SP, MV, DVs, its block diagram and objective ? Tm TT 22 RF , Ti T Process Fluid Condensate Block Diagram for Heat Exchanger Heat Exchanger RF (t), Ti (t) Tsp + TC 22 _ Tm u(t) Steam Valve TT 22 RV (t) Disturbance Path Control Path + + T(t) General Feedback Control Systems Controlled Plant DVs ysp u(t) + ym(t) Controller Final Control Element _ MV Disturbance Path Control Path + + y(t) Sensor & Transmitter CV: temperature, pressure, flow, level, composition( 成份含量) and property(属性) of process fluid; General Control Systems Controlled Plant DVs ysp u(t) + ym(t) Controller Final Control Element _ MV Disturbance Path Control Path + + y(t) Sensor & Transmitter Controller: Hardware & Software Control Strategies / Algorithms (控制策略与算法) Hardware of Controllers Analog control instruments (DDZ-II, III) Digital control instruments (数字控制器) Programmable logic controllers (可编程逻辑 控制器,PLC) Distributed control systems(集散控制系统 或称分布式控制系统,DCS) Fieldbus control system (现场总线控制系统, FCS) Ethernet for Process Automation (过程自动 化以太网,EPA) Types of Control Systems Regulatory Control(“定值控制”或“调节控 制”)and Servo Control(”伺服控制”或“跟 踪控制”) Examples:continuous processes and batch processes or flight control. Feedforward Control(前馈控制)and Feedback Control (反馈控制) Examples:temperature control system in a heat exchanger. Feedforward Control & Feedback Control Tsp Steam RV u(t) Tm Feedforward Controller RFm FT 31 TT 22 RF T TC 22 Steam RV Tm Tim TT 22 TT 32 RF , Ti Ti Process Fluid Condensate Tsp u(t) Process Fluid T Condensate Compare the advantages and disadvantages of both strategies. Feedforward Feedback Control Steam RV Tsp Tm u(t) Feedforward Controller RFm TC 22 FT 31 TT 22 RF T Tim TT 32 Ti Process Fluid Condensate Types of Control Systems Switch Control(开关量控制)and Continuous Control(连续量控制) Examples: air conditioner control Continuous-Time Control(连续时间控制)and Discrete-Time Control(离散时间控制, 也称 “采样控制”, Digital Control, “数字控制”) Examples: control systems based on computers or analog instruments Types of Control Systems (cont.) Multi-input-multi-output Control(MIMO,多 输入多输出控制, or “多变量控制” ), Singleinput-single-output Control (SISO, 单输入 单输出控制)and Multi-loop Control(多回路 控制) Examples: distillation column control Linear Control(线性控制)and Nonlinear Control(非线性控制) Examples: pH control Multi-loop Control for Distillation TC LC FC Processs Fluid FC Distillation Column Product LC Steam Residue Basic Process Control Strategies Single-loop PID (单回路PID控制) Cascade Control (串级控制) Ratio Control (比值控制) Override or Selective Control (超驰或选择 控制)etc. Features: PID based, simple, no model needed, easy tuning, and for SISO systems. Advanced Process Control (先进控制,APC) Strategies Feedforward Control (前馈控制) Dead-time Compensation (纯滞后补偿) Decoupling (解耦), Predictive Control (预测控制) Adaptive Control (自适应控制), etc. Features: Model based, complicated, computer needed, and most for MIMO or SISO systems with long dead-time. Primary Task of the Course Controlled Plant DVs ysp u(t) + ym(t) Controller Final Control Element _ MV Disturbance Path Control Path + + y(t) Sensor & Transmitter To analyze, design and implement the control strategies or controller for continuous controlled processes Techniques Correlative to Process Control Engineering Control Theory System Simulation Optimization Process Control Engineering Chemical Engineering Computer & Networks Measuremental & Control Instruments Next Lecture Defined the types of processes: selfregulating and non-self-regulating processes, single- and multi-capacitance processes ; Discussed the modeling from process dynamics; Discussed process characteristic parameters K, T,τ, and their obtaining methods from process data.