Ventilation of Confined Spaces

advertisement

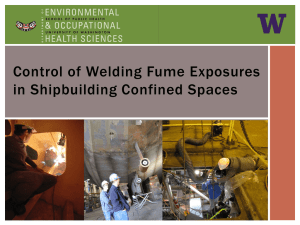

Ventilation of Confined Spaces Confined Space Ventilation Confined spaces are not normally designed for convenient ventilation Must take steps to: • ensure air is breathable before entering confined space • maintain acceptable air quality in the confined space during entry Hotwork in Confined Spaces Presents additional ventilation challenges in confined spaces Includes torch cutting, welding, brazing and soldering, arch gouging Hotwork in Confined Spaces Remember… confined spaces concentrate hazards! Hotwork can create atmospheric hazards in confined spaces from fumes, gasses and vapors Effective ventilation sometimes may only be accomplished by mechanical ventilation Natural Ventilation in Confined Spaces “Chimney Effect” • convection process created by temperature changes Occurs by sunlight heating vessel walls and air within If there is an opening in bottom and top of vessel, upward draft created Natural Ventilation Problems Confined spaces rarely experience uniform thermal conditions Various sources of heat in confined spaces • human bodies • lighting • hotwork processes Natural Ventilation Problems Factors such as sunlight, body heat, lighting and hotwork are usually not sufficient to move enough air to provide an acceptable atmosphere Overcoming Natural Ventilation Problems Must establish techniques and procedures to provide adequate ventilation It is easier to work with than against natural convection. Use of Mechanical Ventilation Properly installed, can reduce or eliminate respiratory protection requirements Effective engineering controls usually less dependent on worker attention than respiratory protection 29 CFR 1910.134 When feasible, effective engineering controls must be used rather than respirators When is ventilation necessary? If atmosphere: • contains insufficient oxygen or is oxygen rich • contains flammable dusts or vapors • contains hazardous or toxic vapors, mists, fumes, gases, or fibers When is ventilation necessary? If atmosphere: • is subject to activities that may generate hazardous mists, vapors, fumes or gases, or may create either an oxygen deficiency or oxygen excess, and • increases heat stress on workers to unacceptable levels CAUTIONS Many people resist wearing PPE, including respiratory protection Tangle of supplied air hoses in vessel with many welders can present a hazard Ventilation- 29 CFR 1910.252(c) Spaces that require ventilation • work space less than 16 feet high • volume less than 10,000 cubic feet per welder • work areas with partitions, structural barriers, or other barriers that significantly obstruct airflow Ventilation- 29 CFR 1910.252 Ventilation options: • provide at least 2000 cfm of airflow for each active welder; or • provide each welder with a local exhaust device – local exhaust devices must be capable of maintaining a velocity of 100 fpm toward the air intake Ventilation Requirements 29 CFR 1910.252 and 29 CFR 1926.353 require use of local exhaust ventilation or supplied air respiratory protection when performing hotwork using certain substances Ventilation Requirements Fluorine compounds Zinc Lead Cadmium Mercury Beryllium (local exhaust and supplied air respirators are required) Ventilation Requirements Construction : • chromium • stainless steels (if using MIG processes) Air Moving Devices Two types: • Fans • Venturi-type eductors Can be air, steam or electrically driven Eductors Sometimes called “air horns” Air powered and rely on venturi effects to move air Criteria for Rating Air Movers Free Air Delivery Effective Blower Capacity Quantity of air and air pressure required (air-driven devices) Electrical power requirements (electrically driven devices) Factors Reducing Performance Equipment components in confined space Maintenance/construction materials erected in space Obstructions in make-up air manway Insufficient number of make-up air manways Factors Reducing Performance More restrictions to overcome = less air moved Air moving into space equals amount of air leaving the space Air Driven DevicesPoor Performance Reduced pressure and volume to air driven devices from multiple users Excessively long air hoses Increasing Performance Supplemental air compressors dedicated to air mover use (air driven devices) Supplemental air compressors connected directly to plant air system Eliminate “short-circuiting” of airflow Designing Ventilation Systems Configuration, contents and tasks determine type of ventilation • opening configuration • properties of expected atmospheric hazards • type of work being performed Electrically Driven Centrifugal Fans Designed to overcome higher static pressures Usually heavier than air-driven equipment Can be used remotely to reduce noise Due to power, can suck up debris Local Exhaust Single manway vessels Interior obstructions that create “dead spots” Lack of feasible way to attach air-moving device Work with toxic metals Local Exhaust Effective only when it captures and removes welding fumes and gasses at the source as they are emitted 100 fpm capture velocity at the source of fumes or gasses Local Exhaust- Considerations Long runs reduce airflow Airflow loss minimized by use of smooth ducting with large radius bends Run flexible ducting as straight as possible Consider using plenums for multiple welders Field test flow/personal air monitors Make-up air quality Mechanical ventilation uses surrounding air Make sure the make-up air is not a source of airborne contaminants