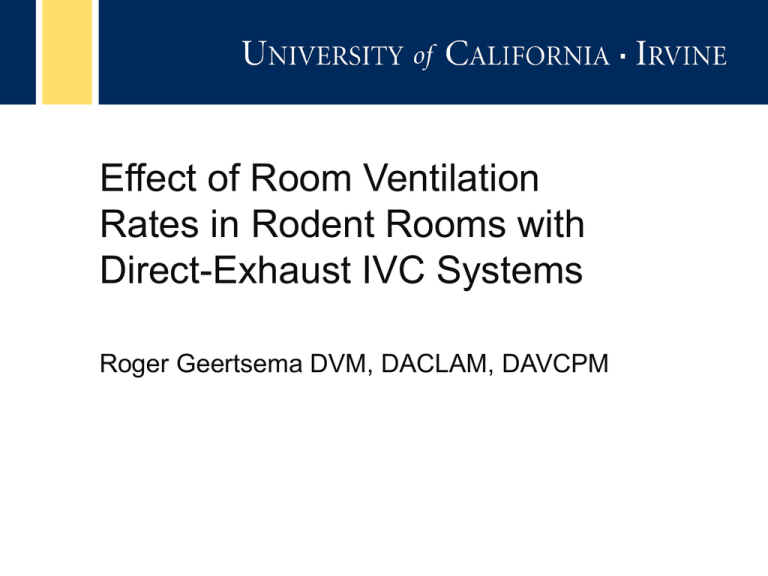

Effect of Room Ventilation Rates in Rodent Rooms with Direct

advertisement

Effect of Room Ventilation Rates in Rodent Rooms with Direct-Exhaust IVC Systems Roger Geertsema DVM, DACLAM, DAVCPM Background • Vivarium with Individual Ventilated Cages (IVC) for rodents with cage exhaust directly ventilated out of room • Tecniplast IVC with positive pressure cages (70% cage exhaust rate) Specific Aims • Can room ventilation rates be safely lowered in rodent rooms utilizing direct exhaust individually-ventilated caging (IVC) • Air quality within the room that could have an occupational health or animal wellbeing effect • Changes in intracage environmental conditions that could impact animal wellbeing or complicate research results Study Design 8 rodent rooms 7 mouse rooms 1 rat room 2 ventilation rates Low: High: 5 – 6 ACH 10 – 12 ACH Period Rats (140) Density of Room in cages/sq.ft. (# of cages in room) 1.2 1.2 0.8 0.6 0.6 0.2 (280) (540) (175) (190) 170) (65) 0.1 (25) 1 High Low Low High High Low Low High 2 Low High High Low Low High High Low 3 High Low Low High High Low Low High 4 Low High High Low Low High High Low Air Flow Room Volume 2800 cu.ft. Room Pressure Differential Positive Cage Pressure Differential Positive Room Ventilation Rate High Low CFM Supply 500 250 ACH 10.7 5.3 CFM from Racks (2) 100 100 CFM for Pressure Offset 100 100 CFM from Room Exhaust 300 50 Ventilation Cost ($3.50/cfm) $1750/year $875/year Study Design Compare Low vs. High room ventilation rates for: • Room CO2 (difference between supply - exhaust air) • Room Dew Point Temperature (difference between supply - exhaust air) • Room Mouse Allergen (Mus m1) • Room Endotoxin • Intracage Ammonia, CO2, Temperature, and Humidity • Create a controlled spill of EtOH in room • Evaluate the peak level and amount of time to return to baseline at Low vs. High ventilation Demand-Controlled Ventilation (DCV) • Computer controlled Phoenix valves in supply and room exhaust • Monitoring of room air quality for temperature, dew point temperature, CO2, dust particles, and Total Volatile Organic Chemicals (TVOC) • Sample taken every 15 min. from room exhaust, not the cage exhaust • Ability to increase ventilation rate based on monitoring parameters Room CO2 Level - Difference between Supply Air 140 * 120 High CO2 (ppm) 100 Low 80 60 40 20 0 Rats 1.2 1.2 0.8 0.6 0.6 Density of Room (cages/sq.ft.) 0.2 0.1 Room Dew Point Temperature - Difference between Supply Air 1.4 1.2 Hi Lo 1.0 °F 0.8 0.6 0.4 0.2 0.0 Rats 1.2 1.2 0.8 0.6 0.6 Density of Room (cages/sq.ft.) 0.2 0.1 Room Level of Mus M 1 Allergen 0.6 0.5 ng/m3 High 0.4 Low 0.3 0.2 0.1 0 0.6 1.2 Density of Room (cages/sq.ft.) Room Level of Endotoxin 0.03 0.025 High ng/m3 0.02 Low 0.015 0.01 0.005 0 0.6 1.2 Density of Room (cages/sq.ft.) CO2 Level within Cages 1400 Hi 1300 Lo ppm 1200 1100 1000 900 800 A B C Cage D Ammonia Level Within Cage at 2 Weeks 35 30 Hi ppm 25 Lo 20 15 10 5 0 A B C Cage D Temperature Difference Between Cage & Room 6.0 5.0 Hi Lo °F 4.0 3.0 2.0 1.0 0.0 A B C Cage D % Humidity within Cage 70% 60% Hi Lo 50% 40% 30% Period 1 Period 2 Period 3 Period 4 Room EtOH Level After a Spill 9 8 7 High Low ppm 6 5 4 3 2 1 0 -5 10 25 40 Minutes After Spill 55 70 85 9 EtOH Level After a Spill with Demand-Controlled Ventialtion (DCV) ppm 8 7 High - without DCV 6 Low - without DCV 5 Low - with DCV * 4 3 2 1 0 -5 10 25 40 55 Minutes after spill 70 85 Summary of Results • • Low ventilation rate: • Slightly increased level of CO2 • Slightly increased Dew Point Temperature • Increased time to clear a VOC spill (demand-controlled ventilation will mitigate this) No difference in: • Mus m1 • Endotoxin • Intracage ammonia, CO2, temperature, and humidity Conclusions • It is safe to lower the room ventilation rate to 5 – 6 ACH both for human workers and animals with a direct exhaust IVC system that is properly designed and maintained - This may not apply to all IVC systems • Although some statistically significant effects were observed, air quality still well within acceptable guidelines (ASHRAE limit for CO2 in room air is 1000 ppm) • With a demand-controlled ventilation system, the air is cleared of a spilled VOC faster (assuming the VOC is able to be detected by the system) Acknowledgements • ACLAM Foundation Grant • Dr. Lindsell, Matthew Gudorf, Alvin Samala, Scott Smith, & Michael Phelan