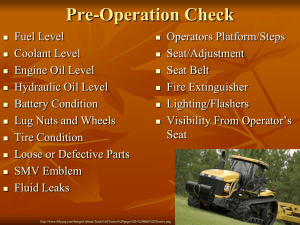

Daily Prestart Check

advertisement

Nicholas Alvarado - AgEd 410, Spring 2013 • • • • • • • Daily Prestart Check Starting a Gasoline Engine Starting a Diesel Engine Selecting a Tractor Forward Speed Selecting an Engine Speed Selecting a Gear Preventing Accidents CLF 2801 Check for coolant, lubricant, fuel, and air leaks Check fuel tank level • • • • • Never let a diesel run out of fuel Drain water and sediment from fuel sediment bowl on gasoline engines Do not mix gasoline and diesel! http://media.treehugger.com/assets/images/2011/10/gasolin e-and-diesel-fuel-photo.jpg Think Why do you think a diesel should never run out of fuel? • Check coolant level in radiator • • a. Coolant should be about one inch below the top of radiator cap Make sure the percentage of antifreeze in the water is adequate by measuring the specific gravity with a radiator hydrometer http://pad3.whstatic.com/images/thumb/6/61/Check-and-AddRadiator-Fluid-Step-5.jpg/550px-Check-and-Add-Radiator-FluidStep-5.jpg http://www.wirthco.com/images/products/21043_ LR.jpg • • Check V-belt (fanbelt) tension and condition Check engine crankcase oil level Make sure oil is not greyish (water in oil) • Add proper engine oil as needed • Some engines can be checked while running • Some older engines have plugs in place of dipsticks • http://mydwsexport.jddistrib.moonda.com/var/plain_site/storage/images/media/productimages-teamsite-commonfolder/salesmanual/sales/salesmanual/images/na/tractors/6d/484601_oil_chec k_gloved_hand_jpg/1353216-1-eng-GB/484601_oil_check_gloved_hand_jpg.jpg • • • • • • • Check transmission and hydraulic oil level Check and clean air cleaner Check condition of air intake hoses and system Check water level and terminals of battery Check tire pressure and condition Check for loose bolts and nuts, tighten as required Grease all lube points http://www.enfostuff.com/images/GreaseGu n.jpg • • • • • • Provide adequate ventilation if engine is to be started inside Check that fuel supply valve is turned on Place transmission shift lever in neutral or park Set speed control lever (hand throttle) at 1/4 to 1/3 open Depress clutch pedal Pull out choke control if engine is cold Click Here if Video Doesn't Play • • • • • Turn ignition switch to on position and crank engine no more than 30 seconds at a time Push in choke control after engine has started and warmed Allow engine to run at a moderately fast speed (1200 rpm) and slowly release the clutch while the transmission still in neutral Check all gauges and warning lights Allow the engine to warm up before work • • • • Provide adequate ventilation if engine is to be started inside Check that fuel supply valve is turned on Put transmission shift lever in neutral or park Be sure fuel stop control is in the non-stopping position (usually pushed in) http://www.oldfordtractors.com/acc/47dash.jpg • • • • Depress clutch pedal, then turn key on to start Crank the engine several revolutions and then open the throttle to at least 1/3 open until engine starts After engine has started, let the engine operate at approximately 1/3 speed for several minutes Immediately after engine starts, release clutch and check gauges and warning lights for normal readings Check For Understanding • What is the reason for checking all of the fluid levels before operating a piece of equipment? • What are the major differences between a diesel and gasoline engine starting procedures? • • • • • • Safe operation is an important determining factor Plowing too fast wastes energy Plowing too slow does not adequately turn over soil Cultivating too fast may cover and bury crop Adequate power capability of tractor is a determining factor Timeliness of completing the job is a determining factor • • • • Selecting engine speed (RPM) For heavy loads, run engine at rated speed (normally 2000 to 2500 RPM) For light loads, engine speed can be lower (usually not less than 1500 RPM) RPM –Revolutions per minute http://www.tractorpart.com/tach.jpg • • • • • Choose gear to keep the engine at desired RPM See the chart on the tractor, or See the tachometer on the tractor or See the chart in the operator's manual Remember, for economical operation, shift up and throttle down http://agriculture. newholland.com/u s/en/Products/Ag riculturalTractors/TV6070BidirectionalTractor/images/T V6070_Transmissio n_chart_fullsize.jpg Check for Understanding • What is the best engine speed to run with a heavy load? • What is the rule of thumb for economical operation? • • • • • Set wheel width at widest setting Lock brake pedals together before operating at transport speeds, or on roads Restrict speed according to operating conditions Do not let the tractor bounce Drive slowly when slippery http://informedfarmers.com/wpcontent/uploads/2011/07/4AzCO-FRUaE3T.jpg • • • • • Pull heavy loads, equipment, and trailers slowly Do not depress a turning brake when turning at high speed Use engine braking when going downhill If possible, avoid crossing steep slopes; turn downhill if stability becomes uncertain Stay a safe distance away from ditch and river banks • • • Hitch towed loads only to the drawbar or drawbar attachment of a three-point hitch When using a drawbar attachment to a threepoint hitch, keep the drawbar attachment as low as possible and use stay braces if possible Use front-end weights or tire ballast to counteract heavy rear loads • • • Start forward motion slowly and change speeds gradually, especially when moving uphill Back up steep hills Back out of ditches or when stuck in mud http://www.me.psu.edu/so mmer/projects/tractor5.jpg • • • • • • Keep steps and platforms clean, dry, and free of oil Do not jump from the tractor Be aware of overhead obstructions such as low hanging limbs Operate the tractor from the operator's platform only Wear the seat belt if the tractor has rollover protection Do not carry riders unless the tractor is equipped to handle them or the passenger is being trained • • • • Place transmission levers in neutral or park and set the parking brake before leaving the tractor Start engine or operate controls only when seated in operator's seat Stay clear of tires when assisting others Stay out of area behind tractor when backing http://www.cdc.gov/niosh/face/images/04mi108a. jpg • • • • On roads, use flashers and lights according to local laws Keep the Slow Moving Vehicle (SMV) emblem clean and visible from the rear of the tractor Pull over to let faster traffic pass Remember that extra weight increases braking distance http://www.semissouri an.com/photos/12/87/ 69/1287695-L.jpg • • • • Always disengage the PTO before getting off the tractor Keep the master shield and implement guard shields in place Check to see that integral shields are in good condition Never step across a rotating powershaft http://web.extension.illinois.edu/agsafety/images/pto_ima ge008.jpg • • • Lower or block hydraulically or mechanically elevated implements before servicing or leaving the equipment Make sure raised equipment does not come in contact with power lines Elevated implements should be lowered before uncoupling remote hydraulic hoses • • • • • Drive in straight lines to decrease wear and to enable precise operation Minimize overlap to decrease cost and time Observe performance of implement Check and listen for proper tractor operation Check gauges and warning lights periodically http://ipcm.wisc.edu/wpcontent/uploads/2013/01/overlappic.jpg http://manuals.deere.com/omview/OMAL2 00158_19/graphics/LX1045005.gif ACTIVITY • Perform a prestart check on a tractor, agricultural machine, or industrial engine • Safely operate three different types of tractors, agricultural machines, or industrial engines