Agricultural Tractor and Machinery Safety Training

advertisement

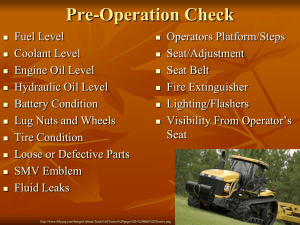

Agricultural Tractor and Machinery Safety Training Chapter 4 Tractors The student will be able to: - demonstrate proper procedure for mounting and dismounting an agricultural tractor. - identify and locate controls on an agricultural tractor. - identify symbols used on agricultural tractors and machinery - perform a pre-operational check on an agricultural tractor. - perform start-up and shut down procedures. The student will be able to: (cont) - describe and demonstrate safe operating procedures. - identify conditions which cause roll over and demonstrate how to avoid roll over situations. - describe and demonstrate procedures for transporting loads. - describe and demonstrate procedures for highway travel. GENERAL MOUNTING AND DISMOUNTING SAFETY PRECAUTIONS - face the tractor at all times. - use the three point contact method. - never mount or dismount a moving tractor. - always use the designated hand holds and steps. - never use control levers as a hand hold and do not step on foot controls when mounting and dismounting. Safety Precautions cont: - never mount or dismount a tractor from the rear. - clean your shoes and wipe your hands before mounting. - never jump off a tractor. - remove any trash or obstructions on the steps or operator’s compartment before mounting. Mounting procedures: 1. Clean shoes of any mud, oil or any other residue preventing firm contact with the steps. 2. Be sure hands are free of any oil or other residue preventing a firm grip of hand holds. 3. Face the tractor operator’s compartment and secure a firm grip with both hands. Mounting procedures cont: 4. Place one foot on the first step, then while using both hands and foot to pull yourself up, place the other foot on the next step. 5. With both feet firmly on the steps, move one hand to secure a second hold and then move the lowest foot on the steps to the next step. Repeat this procedure until you have both feet on the operator’s platform. Mounting procedures cont: 6. With both feet on the operator’s platform and a firm grip with both hands, turn and move one foot to the opposite side of the operator’s platform having the seat behind you. 7. You can now sit in the operator’s seat, and lock the seat belt if the tractor is equipped with a ROPS. Procedures for dismounting a tractor are: 1. Unlock the seat belt, if provided, secure a firm grip with both hands and stand in front of the seat. 2. While still maintaining a firm grip with both hands, move both feet to one side of the operator’s platform. 3. Turn facing the operator’s compartment and while looking at the steps, place one foot on the top step, keeping a firm grip with both hands. Dismounting Procedures cont. 4. Obtain a new grip with one hand if necessary, then move the other foot down to the next step. 5. Repeat step 4 until you have both feet firmly on the ground. 6. Release both hand holds, turn facing away from the tractor and walk away. Controls are devices (typically levers and switches) designed to give the operator a means of communication with the tractor and the ability to regulate and command the tractor to perform all desired responses. The controls are located within reach from the operator’s seat. Agricultural tractors have three basic type of controls. Control Types: 1. Foot controls - these controls are operated by the operator’s feet. 2. Hand controls - these controls are operated by the operator’s hands. 3. Combination controls - these controls can be operated by the operator’s feet and/or hands. The most common is the engine speed control. The nine basic controls common to all agricultural tractors are: 1. Brake control - this gives the operator control over stopping, turning, and parking. 2. Clutch control - this allows the operator to engage or disengage power to moving parts of the tractor. A clutch control can be considered the go-no-go control. This includes: traction controls, combination traction and brake controls, PTO controls, and field implement controls. Basic Controls cont: 3. Engine speed control (throttle)- this allows the operator to regulate the revolutions per minute (RPM’s) of the engine. 4. Ground speed and directional controls (transmission gears)- these controls give the operator control over ground speed (how fast you are traveling) and direction (forward or reverse). 5. Differential lock - this control locks together the rotation of the main drive wheels.Control types continued: Basic Controls cont: 6. Steering control - better known as the steering wheel - gives the operator the ability to turn right or left while moving in either a forward or reverse direction. 7. Electrical controls - these controls are either on or off. Electrical controls activate accessories such as the engine starter and lights. Basic Controls cont: 8. Engine stop controls - on gasoline engines, it stops the spark going to the spark plugs; on some gasoline and all diesel engines, it shuts off the fuel to the engine. Stop controls can be either electrically or manually (push-pull) activated. 9. Lift controls for implements or equipment these are typically hand type controls and give the operator the ability to position or maneuver any attachments into a desired position. NOTE: To find out the specific types and the operation of controls on your tractor, read the operator’s manual. Instruments are the devices that allow the tractor to communicate with the operator and notify him/her of safe and/or unsafe conditions. Instruments may be in the form of a warning light, analog gauge, or digital display. Most Common Instruments used include: 1. Engine speed indicator (tachometer)- this indicator identifies the engine speed in revolutions per minute (RPM). 2. Oil pressure indicator - the oil pressure indicator will either tell the operator the actual oil pressure or warn of low oil pressure during engine operation. 3. Engine temperature indicator- the engine temperature indicator will either indicate actual operating temperature or notify the operator of an unsafe operating condition. Most Common Instruments cont. 4. Electrical system condition - this is commonly referred to as the battery condition indicator. However, it’s actual purpose is to indicate if the electrical charging system is supplying adequate voltage to maintain all electrical components while in operation. 5. Miscellaneous instruments - some manufacturers include a variety of other instruments. Some additional indicators may include: fuel gauge, coolant level, air filter condition, transmission temperature, hydraulic oil level and many more. Operator symbols are visually recognized figures used to transmit information free of words of explanation (ASAE, 1995). The operator symbols are used to identify operator controls, instruments, and servicing locations and/or devices. Hand signals are used when the operator is being assisted by another person. The hand signals become the method of communication between the operator and assistant when noise or distance prevents the use of normal voice communications. Safety signs are a visual alerting device in the form of a decal, label, placard, or other marking such as an embossing, stamping, etching, or other process that advises the observer of the nature and degree of the potential hazard(s) that can cause injury or death. Safety signs can also provide safety precautions or evasive actions to take, or provide other directions to eliminate or reduce the hazard (ASAE). Three basic types of Safety Signs: DANGER - indicates a threatening hazardous situation that, if not avoided, will result in death or serious injury. The signal word “DANGER” is to be limited to the most extreme situations, typically for machine components that, for connection purposes, cannot be guarded (ASAE). Safety Signs cont. WARNING - indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury, and includes hazards that are exposed when guards are removed. The signal word “WARNING” may also be used to alert against unsafe practices (ASAE). Safety Signs cont. CAUTION - indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate injury. The signal word “CAUTION” may also be used to alert against unsafe conditions (ASAE). Pre-operational Check Battery condition - when checking the battery, safety has priority over everything you do. When checking the battery the operator should: Pre-operational Check (battery safety) - wear the proper safety equipment. (gloves, apron, face shield, etc.) - keep fire or flame away from the battery. - inspect for loose and/or corroded connections. Pre-operational Check (battery safety cont.) - inspect electrolyte level (fluid level). (not required on maintenance free batteries) - inspect battery hold down. -- Battery should be secure and unable to move around. Pre-operational Check (battery safety cont.) - inspect condition of cables (cracked, chaffed, torn, or melted insulation). - look for cleanliness of the battery top. --No build-up of trash such as leaves. Pre-operational Check (Fuel, coolant and oil levels) maintaining adequate fluid levels is important to keeping the agricultural tractor running. Fuel level - check the fuel level by removing the fuel cap and visually checking the level in the tank. The fuel level may also be read from a fuel gauge if the tractor is so equipped. Pre-operational Check (Fuel, coolant and oil levels cont.) Coolant - check the coolant level by removing the radiator cap and visually checking for the proper level. WARNING - NEVER REMOVE THE RADIATOR CAP IF THE ENGINE IS HOT. Allow the engine to cool until the radiator is cool to the touch. Pre-operational Check (Fuel, coolant and oil levels cont.) Oil (engine) - check the oil level by removing the dip stick and reading the level indicated on the dip stick. Oil (hydraulic) - Check the transmission and hydraulic oil levels according to the operator’s manual. Pre-operational Check (Fluid leaks) check for any wet or damp areas on the machinery as well as any puddles on the floor or ground under the agricultural tractor. WARNING: When a fluid leak is identified, have the problem corrected before operating the tractor. Pre-operational Check (Tire condition and pressures) check tire condition by looking for cuts, bruises or breaks in the sidewalls, excessive weathering, uneven tread wear, damp spots on tires filled with fluid, and air pressure. See the operator’s manual for correct air pressure. Pre-operational Check (Tractor Tires Servicing procedure:) attach an unpressurized air hose to the tractor tire valve stem. stand to the side, not in front of the tire, and slowly add air pressure using a regulator to avoid excess pressure. with the desired air pressure registering on the gauge, shut off the flow of air to the tire and remove the air hose form the valve stem. Note: some air may escape while removing the air hose depending on the type of connector used. Pre-operational Check (Defective and/or loose equipment) Check for any loose or missing bolts, pins, wiring, or shields. Tighten all loose accessories and guards and replace anything found defective. Air filter - check the air filter every day. Pre-operational Check (Safety devices) this can include fire extinguishers, first aid kit, and safety signs or warning labels. Also check for any safety switches that have been disconnected or bypassed. If a safety switch is not working, have it corrected before operating the tractor. Pre-operational Check (Operator’s compartment) consists of the platform, seat, controls, instruments, and ROPS. Platform - should be clear of any trash, mud or other clutter and have an anti-slip surface. Seat - should be adjustable and positioned to where the operator can reach all controls comfortably. The seat should also be equipped with a seat belt if a Roll Over Protective Structure (ROPS) is attached to the tractor. Pre-operational Check (Operator’s compartment cont.) Controls - should all be identifiable and within comfortable reach of the operator and functional. Instruments - should all be identifiable, functional, and readable from the operator’s seat. ROPS - should be attached according to the operator’s manual with no unauthorized modifications. Pre-operational Check (Cab, if equiped) check for clean, cracked or broken windows. Also check for functional wipers, doors, and clutter that may block your view from any angle. Check mirrors for adjustment and cleanliness. Pre-operational Check (Equipment setup) Check for proper ballasting (weights), Check for properly attached connections, and that you have the proper size tractor for the job. Pre-start Checklist (includes:) 1. Make sure everyone is clear: no one else should be on or next to the agricultural tractor. 2. If parked inside a building, open doors to allow for adequate ventilation during starting. 3. Properly mount the tractor and adjust the operator’s seat. 4. Fasten seat belt if tractor is equipped with a ROPS. Pre-start Checklist cont. 5. Check all controls: place hydraulic controls in a neutral or static position. place three point lift control in a down or locked position. put PTO in an off or disengaged position. place brakes in a set or locked position. set ground speed and directional controls in neutral or park position. Pre-start Checklist cont. 6. Clutch pedal is in disengaged position. 7. Turn ignition switch to “On” position and check gauges and warning lights for operation.Starting a tractor from the ground can result in the tractor riding you instead of you riding it. Pre-start Safety DANGER: NEVER START A TRACTOR WHILE STANDING ON THE GROUND. ALWAYS START FROM THE OPERATOR’S SEAT. DANGER: NEVER BYPASS START A TRACTOR FOR SAFE OPERATION OF TRACTORS: Safe Operating Procedures Watch where you are going, especially at row ends, on roads, and around trees and low hanging obstacles. When backing, use a spotter to guide you when your vision is blocked. To avoid upsets drive the tractor with care and at speeds compatible with safety, especially when operating over rough ground, when crossing ditches or slopes, and when turning corners. Safe Operating Procedures cont. Avoid operating the tractor near ditches, embankments, and holes. Stay off slopes too steep for safe operation. Travel straight up or down a steep slope rather than across it. A bare tractor or tractor with rear mounted attachments should be backed up the slope in reverse and travel forward downhill. Safe Operating Procedures cont. A tractor with a front-end bucket (loader) should travel forward uphill and backed downhill with the loader bucket as low as possible at all times. Lock tractor brake pedals together when transporting on roads to provide two wheel braking. Keep brakes evenly adjusted to provide even braking when brakes are locked together. Safe Operating Procedures cont. Keep the tractor in the same gear when going downhill as used when going uphill. Do not coast or free wheel down hills. Any towed vehicle whose total weight exceeds that of the towing tractor must be equipped with brakes for safe operation. When the tractor is stuck or tires are frozen to the ground, back the tractor up to prevent upset. Safe Operating Procedures cont. Always check overhead clearance, especially when transporting the tractor or towing high objects. When operating at night, adjust lights to prevent blinding an oncoming driver. Make sure seat belt is fastened if ROPS is installed. Do not permit others to ride on the tractor. Tractors have only one seat for one person. Safe Operating Procedures cont. Operate the tractor smoothly - no jerky turns, starts or stops. Hitch only to the drawbar and hitch points recommended, and never above the center line of the rear axle. When the tractor is stopped, be sure the brakes are securely set. Never use attachments unless they are properly matched to your tractor. Operate controls only from the operator’s seat. Safe Operating Procedures cont. Never leave the tractor unattended with the engine running. Pay attention to what you are doing, don’t let a day dream turn into a permanent dream. Never operate nor allow anyone else to operate agricultural tractors or machinery while under the influence of alcohol or drugs. Safe Operating Procedures cont. Do not let your tractor bounce. You may lose steering control. Do not brake suddenly. Apply brakes smoothly and gradually. Never use a tractor to round up farm animals. Prevent Roll-overs by: operating the tractor with care and at speeds compatible with safety, especially when operating over rough ground, when crossing ditches or slopes, and when turning corners. avoiding operation of the tractor near ditches, embankments, and holes. staying off slopes too steep for safe operation. traveling straight up or down a steep slope rather than across it. Prevent Roll-overs by (cont.): backing a bare tractor or tractor with rear mounted attachments up the slope in reverse and travel forward downhill. traveling forward with a front-end bucket (loader) uphill and backing downhill with the loader bucket as low as possible at all times. staying away from ditches and embankments a distance equal to or greater than the depth of the ditch or embankment. Roll-over Warning DANGER - Carelessness on hillsides, around ditches, near embankments and holes can lead to serious injury or death. TRACTOR TO EQUIPMENT CONNECTIONS Connections can be classified as a(n): - single point connection (drawbar connection) - three point connection - PTO connection - hydraulic connection - electrical connection - multiple connection consisting of two or more individual type connections. TRANSPORTATION OF EQUIPMENT AND LOADS - never exceed the rated load capacities of your tractor. - be sure the tractor is properly ballasted for the equipment and/or load. - select a safe ground speed. - always let the engine assist with braking when going down hills. TRANSPORTATION cont. - lock the brakes together. - slow down when making turns and make wide gentle turns. - place all implements into their narrowest transport configuration. - avoid transporting equipment and loads along hillsides and near ditches and holes. TRANSPORTATION cont. - use proper safety hitch pin with safety clip retainer. - raise all implements to their transport position and lock them in place. - allow sufficient clearance for oversize loads. - watch overhead clearance when moving high loads or equipment. PREPARING FOR HIGHWAY TRAVEL - Refer to the operator’s manual for transporting instructions. - Lock the brake pedals together. - Raise all implements to their transport position and lock them in place. - Place all implements into their narrowest transport position. - Disengage PTO and differential lock. HIGHWAY TRAVEL PREPARATION CONT. - Make sure tractor and towed equipment are equipped with SMV(slow moving vehicle) emblems. - Make sure any required clearance flags or hazard lights are in place and in working order. - Make sure you use a proper safety hitch pin with safety clip retainer. - Make sure any towed implements are equipped with a safety chain linking tractor and implement. HIGHWAY TRAVEL PREPARATION CONT. - Clean off all reflectors and road lights, front and rear, and be certain they are in working order. - Familiarize yourself with -- and obey-- all local, state, an federal laws appropriate to your class of equipment. Allowing passengers to ride can become a deadly mistake. RULES OF THE ROAD WARNING: Do not allow any riders on the tractor or towed equipment. Know the route you are going to travel. Use flashing lights when traveling on roads, day or night, unless prohibited by law. RULES OF THE ROAD CONT. Use caution when towing a load at transport speeds. If the towed equipment is not equipped with brakes: DO NOT TOW equipment weighing more than twice the tractor weight. Do not exceed 10 MPH (16 KPH) if the towed equipment weighs more than the tractor. Do not exceed 20 MPH (32 KPH) while towing equipment that weights less than the tractor. RULES OF THE ROAD CONT. Use extreme caution when transporting on snow covered or slippery pavement. Wait for traffic to clear before entering a public road. Beware of blind intersections. Slow down until you have a clear view. Make wide, gentle turns. Signal your intent to slow, stop, or turn. RULES OF THE ROAD CONT. Shift to a lower gear before going up or down hills. Keep tractor in gear. Never coast with clutch disengaged or transmission in neutral. Stay out of the path of oncoming traffic. Drive in the right hand lane as close to the edge as possible. RULES OF THE ROAD CONT. If traffic builds up behind you, pull off the road and let it go by. When pulling off the road, pull completely off the road staying away from ditches and embankments. Drive defensively. Anticipate what other drivers might do. When towing a load, start braking sooner than normal and slow down gradually. Watch out for overhead obstructions.